Air Bubble Rolls: Everything You Need to Know

History of Air Bubble Roll :

The bubble roll was invented by Alfred Fielding and Marc Chavannes in 1957. It has no long history like paper, glue, plastic, or tape. But still, it made its place in the packaging market very prominent. At first, it was used only for greenhouse insulation, but bubble rolls transitioned into the packaging industry.

Functions of Bubble Rolls:

Bubble rolls are not only used in the greenhouse but also by the packaging industry for the protection of the packaging product. It has an outer layer that may be made of paper or plastic, which is flat. The inner layer is rough because of trapped air bubbles. These bubbles provide extra cushioning in transit when the product is wrapped with the bubble roll. It also absorbs shocks and impacts in transit. Thus, bubble roll is not only used to wrap fragile, delicate items like electronics, jewelry, gifts, medications, and documents but is also used for large items like car doors, windows, tables, frames, and paintings to avoid scratches and damage in transit.

How to choose the right bubble roll for the product?

The bubble roll can be chosen based on the length and width of the bubble roll, the different bubble sizes, and the functionality of the bubble roll.

Choosing the bubble roll based on the width and length of the bubble roll:

Selecting the bubble roll based on length and width depends on the following factors:

- What is the length of the product that needs bubble wrapping?

- What is the width of the product that needs bubble wrapping?

- How many products need to be wrapped determines the length of the bubble roll.

- Does the product need double wrapping? If the product is too fragile or has to be protected from scratches in transit, that will determine if it needs double wrapping or not. If yes, then the length of the bubble roll has to be accounted for double wrapping.

- Are the products small or large? This also determines the length and width of the bubble roll.

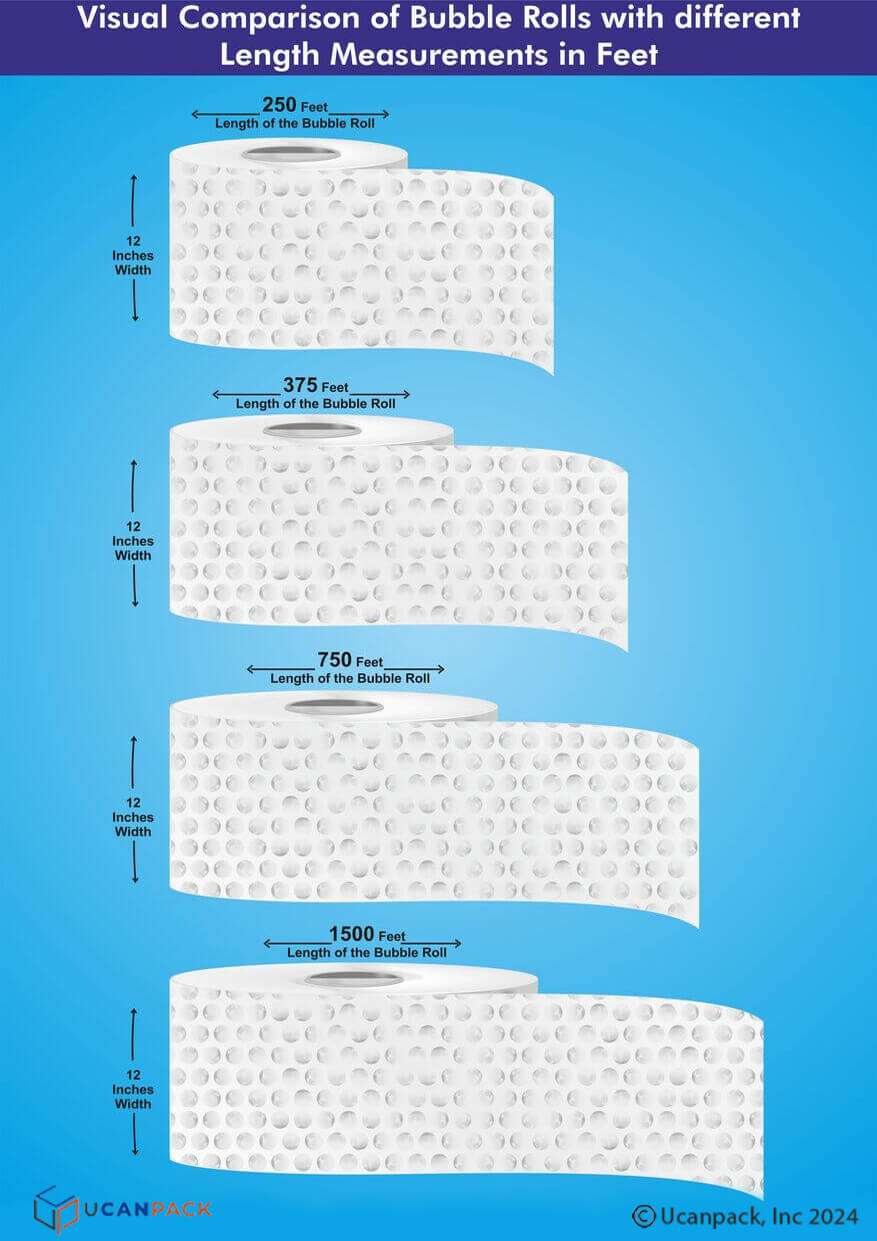

Note: The length of the bubble roll is measured in Feet in the USA.

Note: The length of the bubble roll is measured in Feet in the USA.

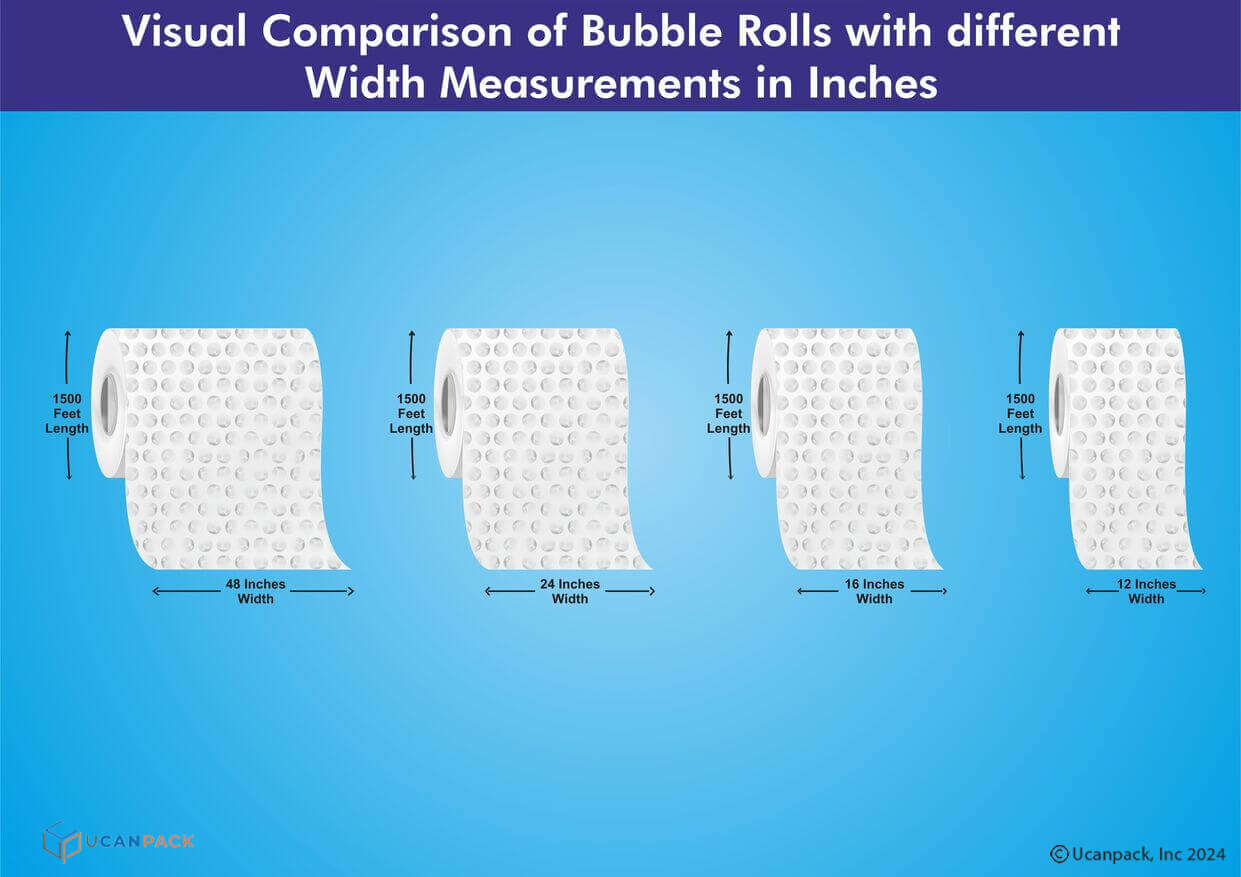

Note: The width of the bubble roll is measured in Inches in the USA.

Note: The width of the bubble roll is measured in Inches in the USA.

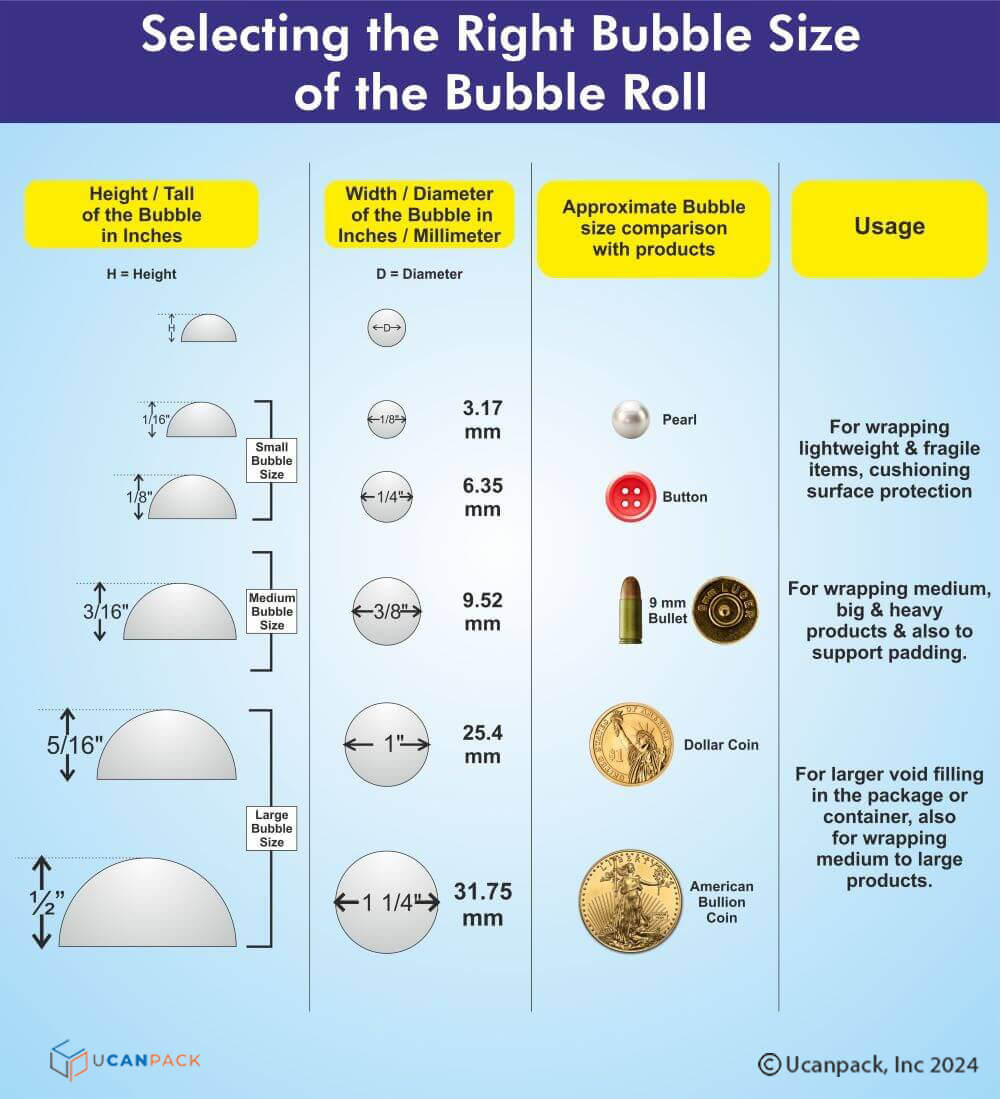

Choosing the bubble roll based on the bubble size:

The bubble roll should be selected based on the type of product that needs to be wrapped, whether fragile or strong. Bubble rolls are made of different bubble sizes. Bubble size is measured by the height of the bubble and the diameter of the bubble. The different bubble rolls with different bubble heights that are available in the market are ¹⁄₁₆”, ⅛”, 3⁄16”, 5⁄16”, and ½”.

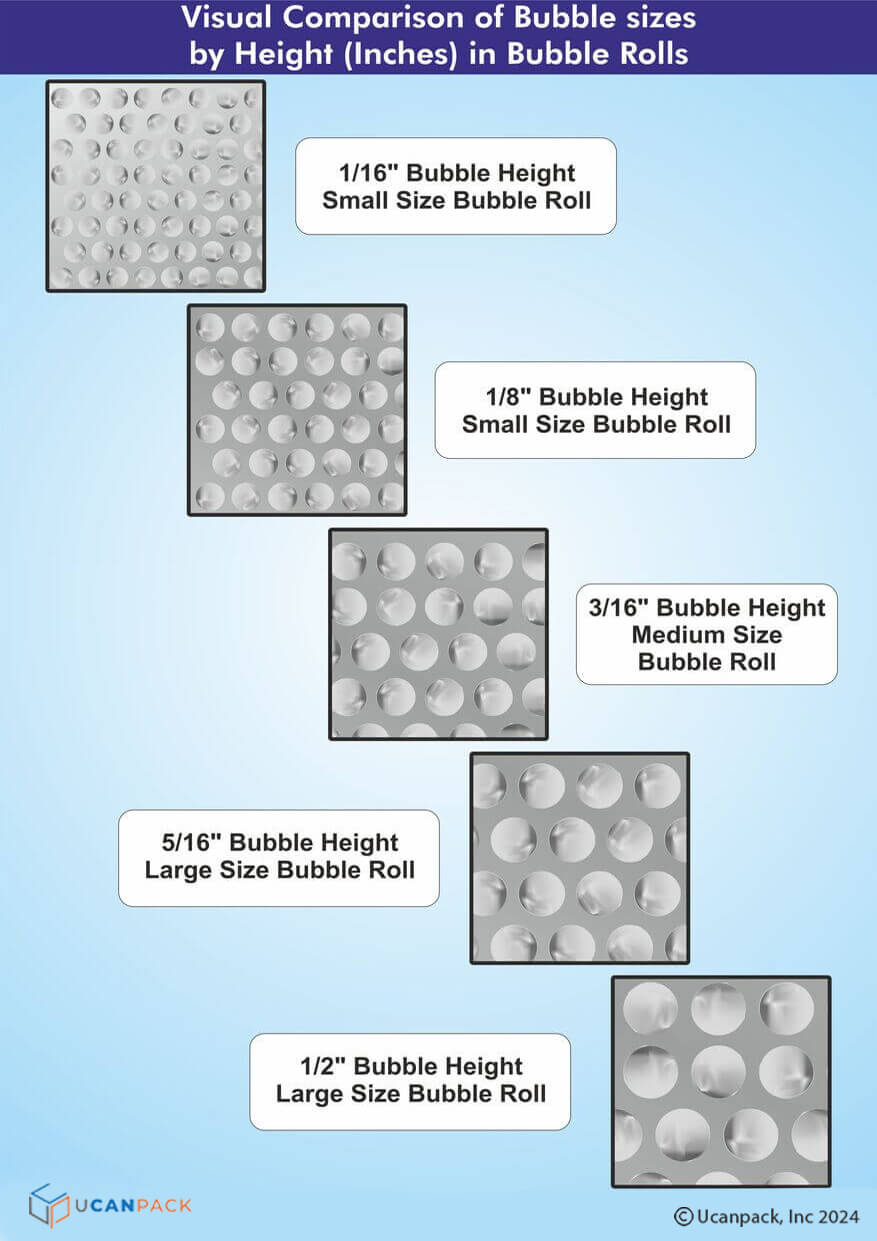

Visual comparison of bubble sizes:

Choosing the bubble roll based on the functionality of the bubble roll:

Choosing the bubble roll based on the functionality of the bubble roll:

Below are the Bubble Rolls based on their Functionality:

Standard Bubble Rolls:

Standard bubble roll protects products against shock, abrasion, vibration, and scratches. 3⁄16” bubble size bubble rolls offer light cushioning for small items; 5⁄16” bubble size bubble rolls provide cushioning for medium and general-purpose items; and ½” bubble size bubble rolls provide cushioning for large items. Standard bubble roll is also called single-layer bubble roll.

Heavy-Duty Bubble Rolls:

Heavy-duty bubble roll is mainly used to give double protection to the product. Heavy-duty bubble roll is stronger than standard roll and is usually used if the product is fragile or needs extra cushioning in transit. It has ½” bubble height and therefore gives extra protection to the packaging product. As a result, it resists tearing, stretching, and puncturing the roll, thus protecting sharp, fragile, as well as heavy products.

Extra Heavy Duty Bubble Rolls:

Extra heavy-duty bubble roll has three-layer bubble protection. It is also called the Super Duty 3rd web roll. They are puncture-resistant and cannot be torn. They are used for wrapping heavy items, parts, tools, sharp objects, metal, or wood products. They have smooth surfaces on both sides, so they can be written on or labeled on any side.

Perforated Economy Bubble Rolls:

Perforation is a row of holes punched into a sheet or roll, allowing for simple tearing at the perforated area without cutting with scissors. To facilitate tearing, perforated bubble rolls have tearing (cross or pre-cut lines) perforations every 12 inches that run at the width of the bubble roll at regular intervals. No use of scissors is required to cut the bubble roll while packing the product. Manufacturers can also create custom perforations for specific product packaging. Perforated bubble rolls save time and labor costs as they are easy to tear while packing the product.

Non-Perforated Economy Bubble Rolls:

Non-perforated air bubble rolls are economical for wrapping products for single use. They are mostly used to fill voids in a package. They are not biodegradable. Non-perforated bubble rolls are bubble rolls with continuous length, and to tear the bubble roll, scissors or knives are required. Non-perforated bubble rolls have the advantage over perforated bubble rolls in that they can be cut to the desired width, unlike perforated bubble rolls, which are precut to 12 inches apart.

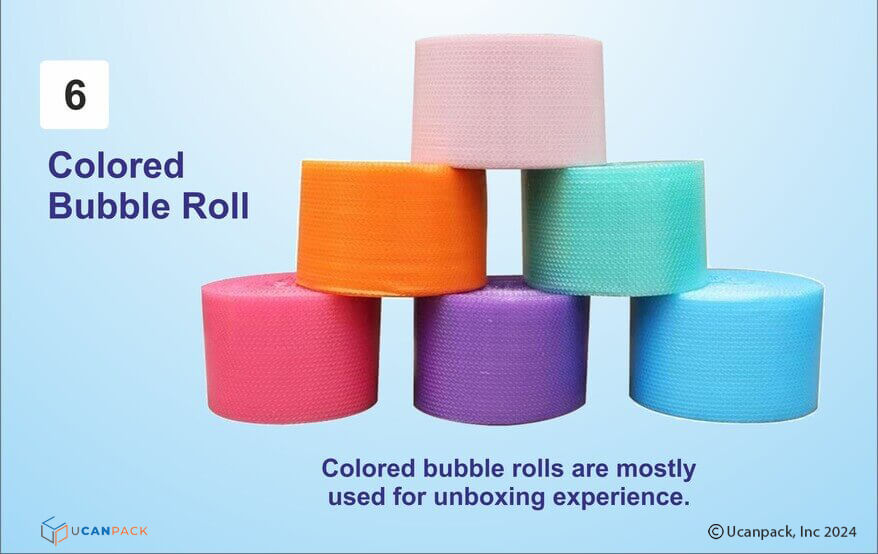

Colored Bubble Rolls:

Colored air bubble rolls not only provide cushion and protection for the packaging product but can also create a memorable unboxing experience for the end user. They come in many colors and sizes: blue, purple, red, yellow, green, and orange. Choosing the right-colored air bubble roll that complements the packaging product creates a memorable unboxing experience for customers.

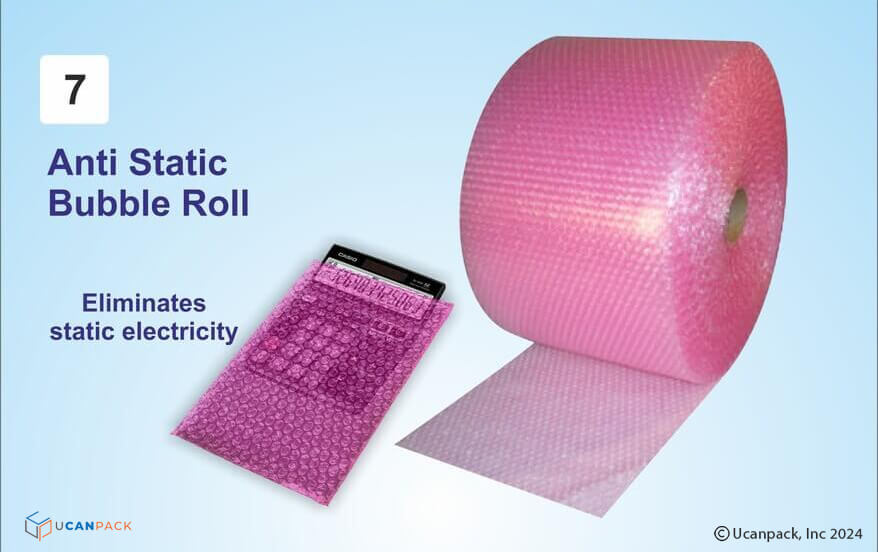

Anti-Static Bubble Rolls:

Anti-static air bubble rolls are low-cost, and they protect electronics from external damage by cushioning them, but they also eliminate static electricity during packaging, storage, and shipping. They are used for cushioning electronic products, gadgets, and parts from static electricity. Most of them are pink in color. They are available as perforated anti-static bubble rolls and non-perforated anti-static bubble rolls.

Eco-Friendly Bubble Rolls:

Eco-friendly bubble rolls provide cushioning and protection to the packaging product as well as support sustainable packaging. They mostly come in two colors: green and blue. Eco-friendly bubble rolls are made from recycled content and thus support environmentally-friendly packaging. They are available in both perforated, eco-friendly bubble rolls and non-perforated bubble rolls. They can be disposed of in curbside recycling.

Self-Adhesive Bubble Rolls:

Self-adhesive air bubble roll when wrapped around the product, sticks to the product but does not leave residue on the product. They are easy to apply and remove, and they provide great cushioning to protect the packaging product. They are usually not recommended for wooden products. They are available in both perforated and non-perforated self-adhesive bubble rolls. No tape is needed when the product is wrapped with a self-adhesive bubble roll.

Cohesive Bubble Rolls:

Cohesive air bubble rolls are bubble rolls that have one side of the roll that sticks to itself when it is wrapped around the packaging product. It does not need tape, which saves packaging costs and packaging time. Cohesive air bubble rolls don't leave any adhesive residue on the wrapped packaging product. They are available in both perforated and non-perforated cohesive bubble rolls.

Cool Shield Bubble Rolls:

Cool shield air bubble rolls are mainly used for the thermal packaging of food, medical products, and plants to protect them from moisture, odor, temperature, and vapor. It has a metalized bubble cushion, which stops heat transfer to the wrapped product through radiation. They are usually a silver-metalized color and FDA-compliant for involuntary contact with food.

Black Bubble Rolls:

Black bubble rolls are used for wrapping fragile and expensive products, as they hide the product until the end user unwraps it. They come in UPSable sizes and in black matte and black glossy styles.

Kraft Bubble Rolls:

Kraft Air Bubble Rolls are made of Kraft paper at the top instead of plastic, like other air bubble rolls. It has laminated paper on top of the plastic bubble roll. Kraft bubble rolls are mostly used for wrapping fragile and small items. Because of the way the kraft bubble roll is constructed, packaging products can only be seen by the end-user when opened. Thus, not only does it provide privacy for the item that is shipped, but it is also water-resistant, strong, and flexible. Kraft bubble roll has one smooth side, so the label can be easily stuck to it.

Foam Bubble Rolls (Laminated Bubble Rolls):

Foam bubble rolls are also called laminated bubble rolls. Foam air bubble rolls are laminated with polyethylene foam backing on one side and a rugged plastic bubble surface on the other side. They are tear-resistant, puncture-resistant, flexible, and have convenient labeling. Most foam bubble rolls have an opaque-colored foam backing, thus protecting the wrapped product's privacy. When the foam side of the wrapped product is facing it, it protects the surface from scratching. Therefore, people typically use it when they suspect that a regular bubble roll's rough surface could harm the product. You can use foam bubble rolls to wrap both fragile and heavy products, such as jewelry, furniture, and everything in between.

Parcel Ready Bubble Rolls:

Parcel-ready bubble rolls are special rolls that have a length and width that meet UPS shipping guidelines. They are excellent choices for small businesses with low-volume packaging requirements. They are also referred to as UPSable bubble rolls, which are ideal for packaging small items. If the product's bubble wrap doesn't adhere to UPSable shipping guidelines, the customer may receive an LTL (less than a truckload) shipment. Therefore, products that fit a UPSable bubble roll while wrapping it are called parcel-ready bubble rolls.

Below is the table of the most common UPSable bubble roll sizes:

|

Bubble Size (Inches) |

Bubble Roll Size (width x length) (Inches x Feet) |

|

3⁄16” |

12” x 300’ |

|

3⁄16” |

24” x 300’ |

|

3⁄16” |

48” x 300’ |

|

3⁄16” |

48” x 190’ |

|

5⁄16” |

12” x 188’ |

|

5⁄16” |

24” x 188’ |

|

5⁄16” |

48” x 188’ |

|

½” |

12” x 125’ |

|

½” |

24” x 125’ |

|

½” |

48” x 125’ |

|

½” |

24” x 100’ |

FDA Approved Bubble Rolls:

FDA-approved bubble rolls are the rolls that are approved by the Food and Drug Administration. These bubble rolls can be used to wrap products that may come into contact voluntarily or involuntarily with food, plants, or medicinal products. These bubble rolls have certification and are made sure that their contact can do no harm to living beings.

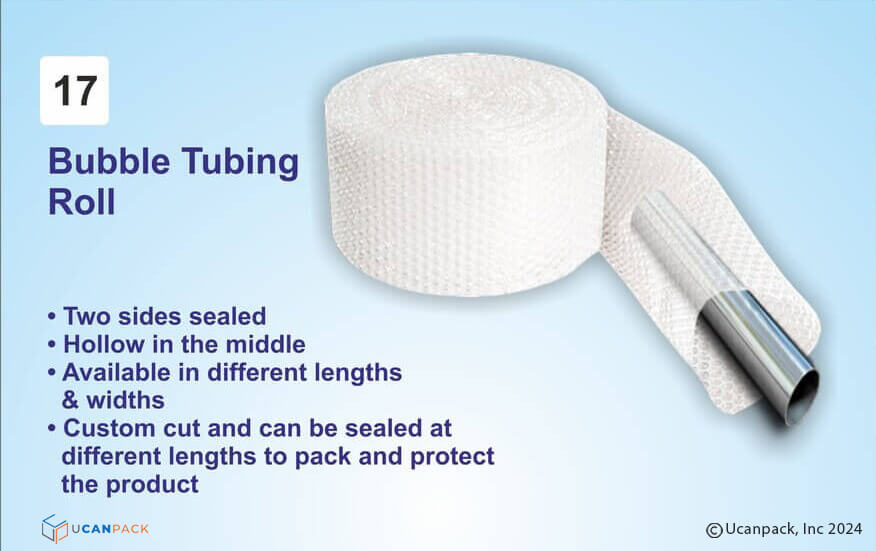

Bubble Tubing Rolls:

The two sides of bubble tubing rolls are sealed. This creates a tube. It’s hollow in the middle. The roll is available in different lengths and widths. They can be custom cut and sealed at different lengths to pack, seal, and protect the product. They are available in standard as well as anti-static grades. Thus, bubble tubing rolls save time and money as they don't have to be taped or sealed all four sides.

VCI (Volatile Corrosion Inhibitor) Bubble Roll:

VCI bubble roll is used for cushioning, protecting and wrapping metal and jewelry products. They are mainly used to prevent rust, moisture, and air from entering the product during shipping and storage. They are mostly blue in color.

Here's the detailed table for the different types of bubble rolls:

|

Type |

Characteristics |

Usage |

Color |

|

Standard Bubble Rolls (3/16") |

Light cushioning for small items |

Small items |

Clear |

|

Standard Bubble Rolls (5/16") |

Cushioning for medium items and general-purpose |

Medium items |

Clear |

|

Standard Bubble Rolls (1/2") |

Cushioning for large items |

Large items |

Clear |

|

Heavy Duty Bubble Rolls |

Stronger than standard rolls, used for fragile products |

Fragile, sharp, heavy products |

Clear |

|

Extra Heavy Duty Bubble Rolls |

Three-layer bubble protection, used for heavy, sharp items |

Heavy items, parts, tools, sharp objects, metal, and wood products |

Clear |

|

Perforated Economy Bubble Rolls |

Perforated every 12 inches, easy to tear |

Saves time and labor costs |

Any color |

|

Non-Perforated Economy Bubble Rolls |

Economical, used for single use |

Fill void spaces in a package |

Any color |

|

Colored Bubble Rolls |

Available in various colors: blue, purple, red, yellow, green, orange |

Creates a memorable unboxing experience |

Blue, Purple, Red, Yellow, Green, Orange |

|

Anti-Static Bubble Rolls |

Low-cost, eliminates static electricity, protects electronics |

Protects electronics from damage and static |

Pink |

|

Eco-Friendly Bubble Rolls |

Provides cushioning and supports sustainable packaging |

Sustainable packaging |

Blue, Green |

|

Self Adhesive Bubble Rolls |

Self-adhesive, leaves no residue, used for all products except wooden |

Cushioning all products except wooden |

Any color |

|

Cohesive Bubble Rolls |

One side sticks to itself when wrapped around the product |

All cushioning products |

Any color |

|

Cool Shield Bubble Rolls |

Thermal packaging, protects from moisture, odor, temperature, vapor |

Food, medical products, plants |

Silver-metallized |

|

Black Bubble Rolls |

Hides the product, available in black matte and black glossy |

Fragile and expensive products |

Black matte, black glossy |

|

Kraft Bubble Rolls |

Water-resistant, strong, flexible, used for small fragile items |

Small fragile items |

Brown |

|

Foam Bubble Rolls (Laminated) |

Tear-resistant, puncture-resistant, flexible, opaque colored backing |

Jewelry, furniture, heavy products |

Opaque |

|

Parcel Ready Bubble Rolls |

Meet UPS shipping guidelines, excellent for small businesses |

Small businesses with low-volume packaging |

Clear, Pink or any color |

|

FDA Approved Bubble Rolls |

Approved by FDA, safe for contact with food, plants, medicinal products |

Products that may come into contact with food, plants, medicinal products |

Clear |

|

Bubble Tubing Rolls |

Tube Rolls can have custom cut, to pack, seal and protect the product. |

For easy packing, it does not need all the four sides to be sealed or taped. |

Any color |

Featured Products

Check all our featured products

How to wrap the product with a bubble roll?

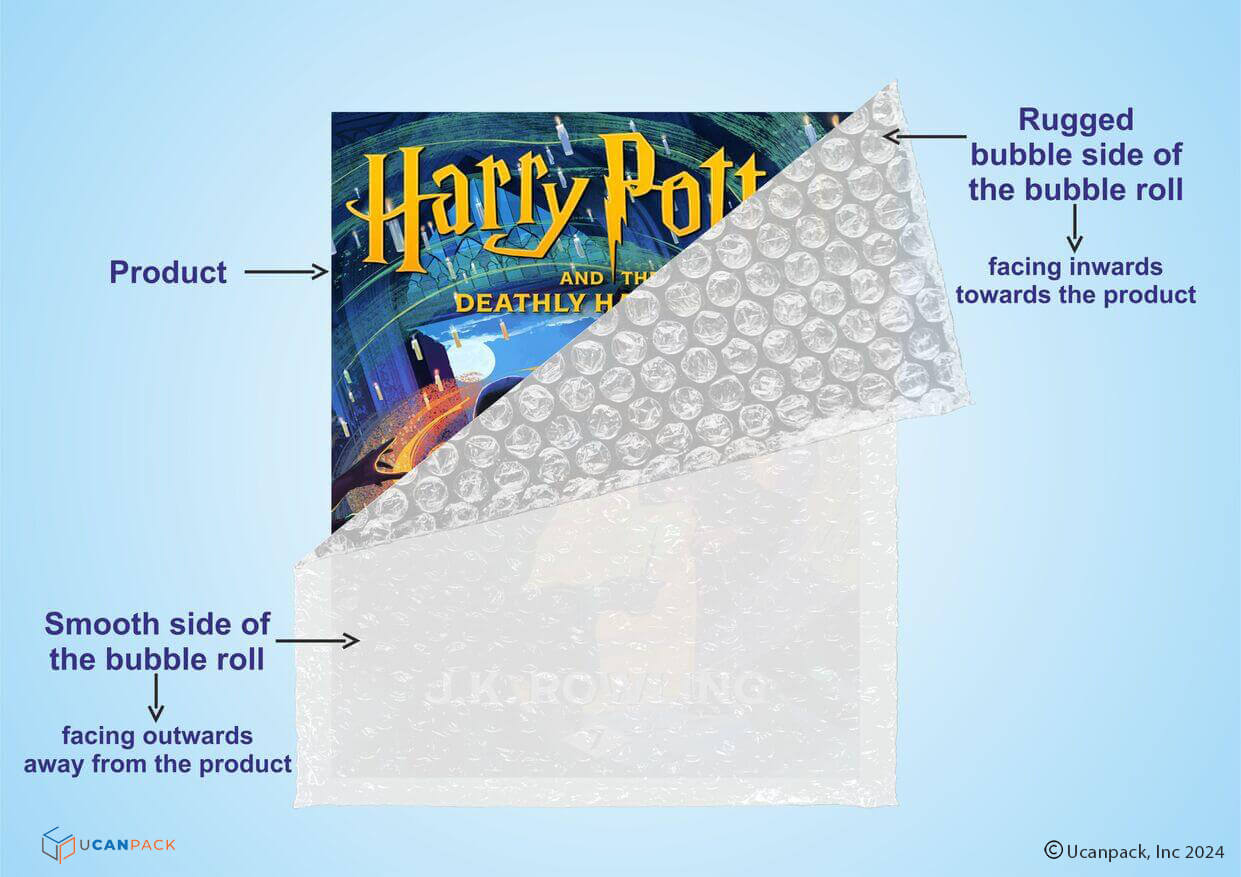

Bubble roll has two sides: a smooth side and a rugged bubble side. To wrap your product with bubble roll, follow the below steps:

-

- Measure the product's length and width.

- Purchase a bubble roll that aligns with the product length, width, and the right type of bubble roll required for the product.

- Place the product on a clean, flat surface.

- Cut the bubble roll to the right length and width that will fit the product when wrapped around it.

- Place the bubble roll on a flat surface on the side where the product is placed. Make sure the rough bubble side of the bubble roll is facing upwards and the flat side of the bubble roll is facing towards the flat side of the surface.

- Place the product on the bubble roll with the rough bubble side facing up. Wrap it around the product. Make sure that the bubble side of the bubble roll always faces towards the product.

- Make sure all of the product's corners and edges are covered, and tape it at the end. If it's a cohesive or adhesive bubble roll, there is no need to tape it; it sticks to the product or to the bubble roll itself.

- Finally, if the product is too fragile and requires double wrapping of bubble roll, then double wrap the product with extra bubble roll.