Top-Quality Inspection Tags: Maximize Compliance & Safety

Inspection tags facilitate efficient management of your inventory. They are made with a tear-resistant, durable material, and come in a convenient size to easily attach to different products.

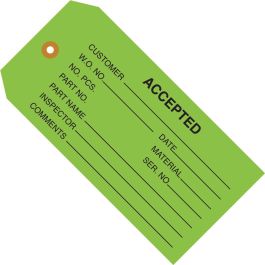

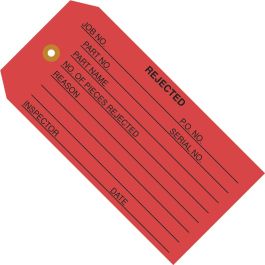

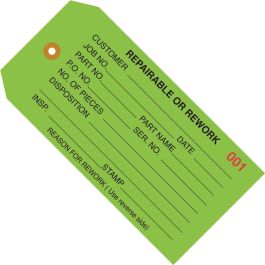

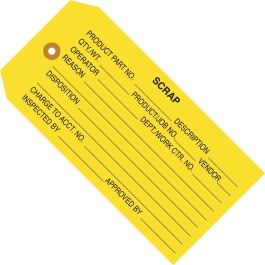

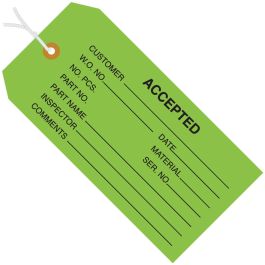

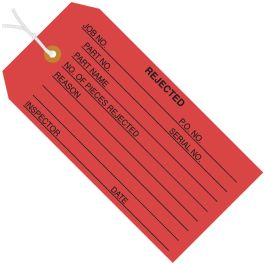

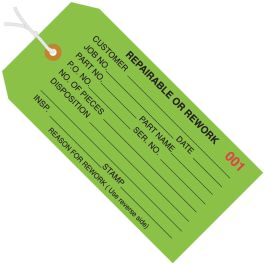

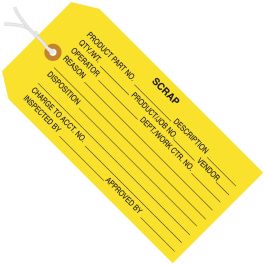

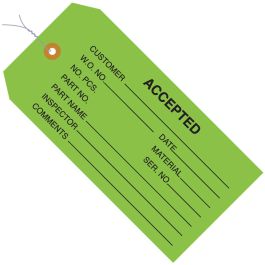

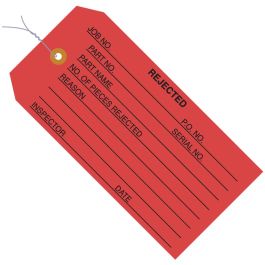

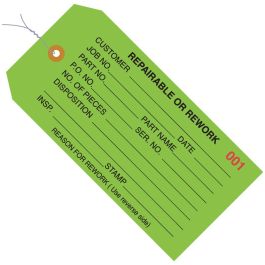

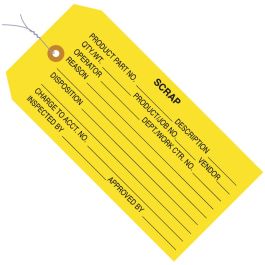

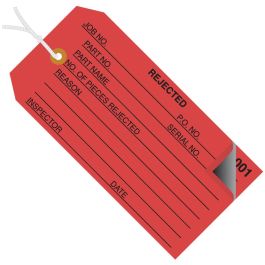

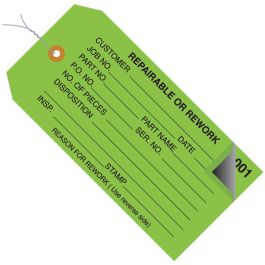

We provide pre-printed tags with ample space for adding essential information like inspection status, including the inspector's name and date of inspection, making them useful for various industries like automotive, construction, manufacturing, and utilities.

Benefits Of Using Inspection Tags: Monitor Status Of Products & Equipment

Color-Coding: Streamlines the inspection process by marking accepted or rejected items and provides efficient solutions for organizing and labeling the shipments. Color coding also makes for easy visual inspection to demarcate between products segregated by inspection status.

Easy-Communication: Using the tags communicates the status of accepted, under inspection, or rejected items to facilitate quick sorting. For instance, the Accepted Inspection Tags denote the inspected item has cleared quality and standard checks and received approval for the next process or shipping. It helps to understand the stages that need rework in quality control departments, warehouses, distribution centers, or manufacturing plants.

Minimizes Confusion: The easy identification lowers confusion risks or workflow errors, promoting efficiency and time management.

Large Quantity: There are 1000 tags in each case to ensure the supply is sufficient for the long run, without requiring frequent re-stocking.

Easy to Attach: They can be easily attached to shipment boxes, cargo, crates, and individual items with the pre-wire and stay securely in place.

Variety: Inspection tags are available in different types to suit multiple purposes. They include Accepted Inspection Tags, Rejection Inspection Tags, Rework or Repairable Inspection Tags, Scrap Inspection Tags, and Inspected Inspection Tags.