Beyond the Box: Using Cardboard Sheets and Dividers to Protect Your Shipments

A box alone never tells the full story of safe shipping. Every business that packs and ships knows the uneasy moment before a delivery reaches its customer. Will everything inside arrive the way it left?

This is where protective packaging earns its reputation. While most conversations center on box strength or outer packaging, the real heroes of safe transit often stay hidden inside the box: corrugated cardboard sheets and shipping box dividers.

In fact, recent industry moves reflect this growing focus. Packaging manufacturers across the U.S. are pushing new standards for product safety, combining engineered dividers, corrugated/ inserts, and foam supports to minimize in-transit damage and make the customer experience better. This is a trend shaping packaging decisions far beyond the retail shelf.

Businesses shipping across the United States, whether handling delicate glassware, bulk industrial parts, or retail items, rely on these internal protectors every single day.

The Science Behind Internal Packaging Protection

Most products shift, settle, or face stacking pressures during shipping. Whether packed in heavy-duty shipping boxes or standard cartons, internal movement remains a constant threat.

A smart packaging strategy views the inside of the box as the first defense line, not an afterthought.

Cardboard sheets distribute weight evenly, protect against crushing forces, and act as moisture barriers inside boxes stacked on pallets or during long-haul transport.

At the same time, cardboard box dividers control internal movement. They compartmentalize, separate, and hold products steady even when handled roughly during multi-stop logistics routes.

These are not optional accessories; they are calculated tools in supply chain protection.

How Corrugated Cardboard Sheets Support Structural Integrity

You might see a flat sheet. We see load management.

When shipments stack, the pressure on the bottom box can easily cause crushing or collapse, especially under warehouse racking or during cross-country transport.

Sliding a corrugated cardboard sheet at the base or between product layers redistributes weight and reduces direct impact. This simple addition increases stacking strength without switching to higher-cost double-wall cartons.

Where sheets make the biggest difference:

- Palletized shipments with mixed goods

- Bulk stacking in warehouses

- Long transit routes with variable handling

Many U.S. manufacturers now request single wall kraft cardboard sheets for this purpose, maximizing both protection and cost efficiency which is a smart move for B2B shipping that values consistency over guesswork.

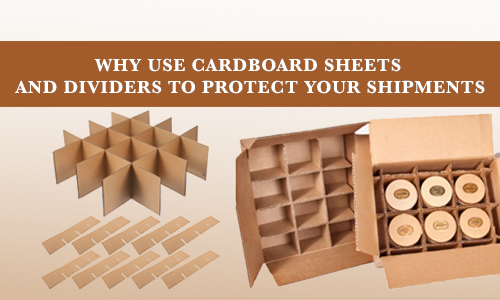

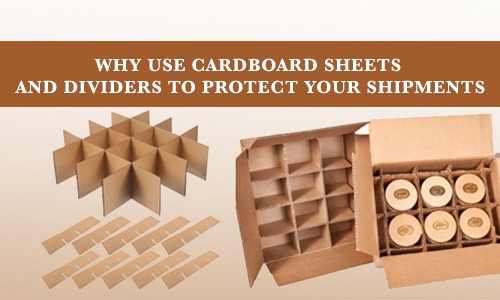

Why Dividers Matter More Than You Think

Internal dividers often get dismissed as "only for fragile items." That thinking limits your protection potential.

Dividers matter whenever movement within a box threatens product condition, even if the item itself is not breakable.

Think of it this way:

- Loose-packed products can shift, scratch, or crush each other.

- Box integrity weakens when items rattle against the walls.

- Dividers help balance the internal load, giving structural support from the inside.

From heavy-duty dividers for shipping industrial components to simple cardboard inserts for retail kits, businesses that integrate smart dividers reduce returns, complaints, and costly re-shipping.

Combining Sheets and Dividers for Maximum ProtectionLorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

No single packaging solution solves every transit challenge.

But pairing corrugated cardboard sheets with shipping box dividers turns any box into a multi-layer defense system.

Imagine a shipment of specialty glassware in heavy-duty shipping boxes:

- A base sheet supports the first layer

- Custom-fit dividers separate each item

- An interlocking top sheet secures everything in place before sealing

The result? Stable, protected shipments even on routes with multiple handling points. It minimizes both damage and claims.

The Overlooked Impact on Freight Efficiency

What protects your products can also protect your bottom line.

Correctly sized dividers and sheets reduce dead space inside cartons. That leads to better freight density, fewer required shipments, and lower dimensional weight charges which is a major factor with modern logistics carriers.

For example:

- Retail brands use custom cardboard box dividers to pack more units per carton

- Distribution centers optimize pallet loads by eliminating unused carton space

- eCommerce businesses cut down on void fill and unnecessary cushioning materials

Over time, these efficiencies save on both shipping costs and warehouse handling.

Automation Meets Packaging: Getting Your Inserts Right

Automated packing lines demand precision.

Your protective packaging must integrate seamlessly into fast-moving systems, whether it is box erecting machines, automated fillers, or sealing stations.

UCanPack works with businesses that run automated lines, supplying corrugated cardboard sheets and dividers crafted with machine-precision cuts and scoring.

This eliminates jams, reduces manual intervention, and keeps production moving at peak speed, something off-the-shelf solutions often fail to do.

When packaging aligns with automation, efficiency scales without sacrificing protection.

The Real Cost of Skipping Internal Protection

Internal packaging comes with a cost per unit but skipping it comes with costs that last much longer.

Returns, damaged goods, negative customer reviews, and shipping claims all chip away at profit margins and business reputation.

The table below shows how small savings on internal protection often lead to much bigger costs across operations and customer relationships.

| Scenario | Immediate Cost Impact | Long-Term Business Impact |

| Minor Product Damage | Replacement shipping cost | Lower customer trust |

| Major Product Damage | Full refund or claim cost | Risk of losing repeat business |

| Frequent Damaged Deliveries | Increased claims handling | Negative online reviews |

| Damaged Bulk/Wholesale Orders | Lost client account | Strained B2B relationships |

| Product Arrives Intact with Dividers | Slight packaging cost increase | Higher customer satisfaction, better brand perception |

So, smart businesses view internal packaging as a risk management tool, not a line-item expense.

Why Testing Matters More Than Guesswork

In packaging, assumptions cost money.

That is why professional-grade inserts and dividers are tested under real-world shipping conditions including compression, vibration, drop, and humidity standards.

Domestic packaging suppliers ensure that every corrugated cardboard sheet and divider meets established ASTM and ISTA performance standards before it reaches your production floor.

And if you want a clearer insight into how local suppliers compare with global sourcing partners, especially in areas like quality control, customization, and supply chain flexibility, you might find this comparison worth a look: Think Local or Go Global? Domestic vs Overseas Packaging Suppliers Explained.

The final result? Confidence that your packaging works as hard as your product does.

Building Packaging Strategy With Your Supplier, Not Around Them

Strong packaging decisions do not happen in isolation.

The best results come when you collaborate directly with your packaging supplier, working out protection needs, automation compatibility, and shipping conditions together.

Partnering with a reliable US packaging supplier, businesses can benefit from direct engagement with packaging engineers who understand both product behavior and supply chain demands.

So, if it's prototyping a custom divider set or crafting pallets with strategic sheet layering, these partnerships keep your shipments moving safely.

Situations That Demand Internal Protection: A Quick Checklist

Some products make internal packaging an absolute must.

If your business deals with any of the following, protective inserts are not optional, they are expected.

- Fragile items like glassware, electronics, or ceramics

- High-value products with sensitive finishes or surfaces

- Multi-SKU packs combining varied weights and shapes

- Long-haul shipments facing cross-docking or multiple handlers

- Brand experiences that rely on premium unboxing

In these cases, even a small investment in the right inserts protects your product, your reputation, and your bottom line.

Thinking Ahead: Protective Packaging as Part of Brand Experience

Today's customers, both retail and B2B, pay attention to how products arrive.

Internal packaging directly influences the unboxing experience, product presentation, and perceived value.

By using custom dividers and clean-cut sheets, businesses deliver a more organized, thoughtful package, reflecting professionalism before the product even gets used.

Customizing Inside the Box Builds Brand Impact

A tailored unboxing does not stop at branded outer packaging. Thoughtfully designed internal protection, be it is sized dividers, color-matched sheets, or branded inserts, can create a sense of care and attention that customers remember.

Even standard shipping items feel elevated when the packaging inside looks planned, clean, and consistent with your brand’s tone.

UCanPack supports this experience by offering customizable corrugated cardboard sheets, including color options, so businesses can align even their protective packaging with their brand identity, without compromising strength or functionality.

A Final Thought on Packaging Protection That Works with Your Business

Every shipment carries both your product and your promise.

The right combination of corrugated cardboard sheets, heavy duty shipping boxes, and shipping box dividers ensures that promise arrives intact, every single time.

Protection inside the box reduces risk outside it - for your reputation, your logistics budget, and your customer relationships.

If you are ready to strengthen your packaging strategy with a partner who understands the realities of modern shipping, UCanPack stands ready with tested solutions, hands-on support, and products built for business.

Ready for smarter packaging that protects your product and your promise?

Partner with ucanpack.com, your trusted domestic packaging supplier for practical, proven solutions.