The Ultimate Guide to Box Maker's Certification and Box Strength Tests

Which Certification determines Box Strength made from different Corrugated Cardboard Sheets?

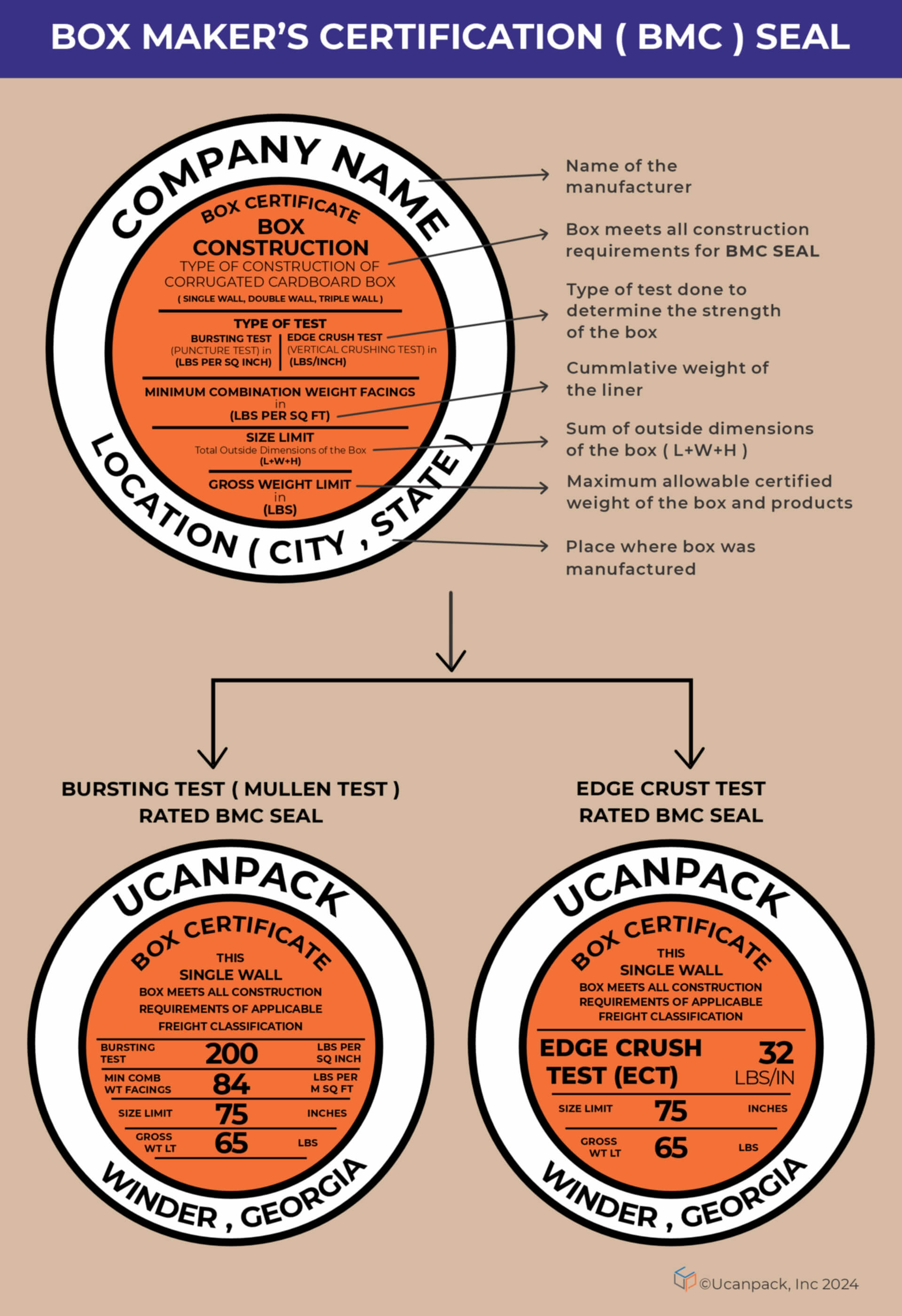

Box manufacturing companies stamp certified seals at the bottom of the box called the Box Maker's Certificate (BMC). The seals give information on the type of corrugated sheets used to make the box and its strength.

What is Box Maker's Certification (BMC)?

Box Manufacturer Certification is also called Box Maker's Certificate (BMC). Box Maker's Certification (BMC) is usually found as a label, print, stamp, or seal at the bottom of the box. BMC seal gives information about the manufacturing company and the box's strength. It provides information on the box manufacturer, size, weight, and limitations of the box.

What information does the Box Maker's Certificate (BMC) Seal give about the box?

Box Maker's Certification (BMC) has the following information:

- Box Manufacturer: The name of the company that manufactured the box is on top of the outer circle. The box may have manufacturer information, either in the form of a name or logo. This helps ensure complete knowledge of the box where it is manufactured, and thus, customers know whom to contact when they have any questions.

- Box Construction: Type of Corrugated Cardboard Sheet used in making the box, whether single-wall corrugated sheet, double-wall corrugated sheet, or triple-wall corrugated sheet and flute type. It gives information on the thickness of the box. This information can help select the right box size for the product for storing, stacking, and shipping purposes. To know more about different types of Corrugated Cardboard Sheets, please visit….The Ultimate Guide to Different Types of Corrugated Cardboard Sheets

- Strength of the Box: Which tests are done on the box to measure the strength or weight-bearing capacity of the corrugated cardboard sheet used to make the box: the Edge Crush Test (Crush Test) or the Mullen Test (Burst Test)? To know more about the Edge Crush Test and Mullen Test( Bursting Test), please visit: 200# and 32 ECT Boxes.

The Edge Crush Test shows the maximum weight pressure in pounds (lbs) the corrugated box can withstand per inch at the edge before it crushes. The edge crust test is done vertically on the corrugated cardboard sheet, thus measuring the crushing strength of that corrugated sheet. This can help determine the box's stacking strength.

The Mullen Test shows the maximum weight pressure in pounds (lbs), and the corrugated box can withstand per square inch without bursting or puncturing. The Mullen test is done horizontally on the corrugated cardboard sheet. Thus, it measures the busting strength of the corrugated cardboard sheet. This can help determine the box's containment strength or weight-bearing strength. This test is best used when shipping heavier products to ensure the correct strength is correct. The strength box packs heavy products so they are not damaged in transit.

It's essential to know which test is on the BMC seal. A box with a BMC seal with the Mullen test has more weight-bearing capacity than a box with the BMC seal of ECT. Thus, the box selection for BMC seals should depend on the product weight.

- Minimum Combination Weight Facings: The cumulative weight of the liner in pounds (lbs) per M Sq Ft. before constructing the box. This reading is only available in the Box Maker Certificate(BMC), where the box only has the Mullen Test reading. This information gives manufacturers leverage to design boxes with more customized weights. These readings are basically of the non-cut liner in pounds per meter square inch.

- Size Limit: The maximum total sum of the box's outside dimensions (length + width + height). The size limit helps determine the product's weight distribution in the box.

- Gross Weight Limit: The maximum weight of the product the box is certified to carry to prevent the box from rupturing or breaking in storage or transport. The gross weight limit is an approximate value only.

- Location of the Manufacturer: The manufacturer's location is at the bottom of the outer circle. The area provides information about the city and state where the box is manufactured, which can help trace shipping requirements.

What are the parameters of a BMC seal of a corrugated box?

Parameters of the BMC seal have information of Type of Corrugated Fiberboard Box, Bursting Test, ECT Test, Minimum Combination Weight Facings, Size Limit, Gross weight Limit. It is easier for customers to make correct choices for their product by using the standard parameters of the BMC seal of a corrugated fiberboard box.

Below is the Table that explains Parameters of the BMC seal of different Corrugated Fiberboard Boxes:

BMC Seal of Single-wall Corrugated Box with Edge Crush Test(ECT):

|

Gross Weight(LBS) Max Weight of Box and Products |

Edge Crush Test(LBS/INCH) (ECT) |

Size Limit(INCH) (L + W + H) |

|

20 |

23 |

40 |

|

35 |

26 |

50 |

|

50 |

29 |

60 |

|

65 |

32 |

75 |

|

80 |

40 |

85 |

|

95 |

44 |

95 |

|

120 |

55 |

105 |

BMC Seal of Single-wall Corrugated Box with Mullen Test(Bursting Test):

|

GrossWeight(LBS) Max Weight of Box and Products |

BurstingTest(LBS PER SQ INCH) Mullen Test |

Minimum Combination Weight Facings(LBS PER M SQ FT) |

Size Limit(INCH) (L + W + H) |

|

20 |

125 |

52 |

40 |

|

35 |

150 |

66 |

50 |

|

50 |

175 |

75 |

60 |

|

65 |

200 |

84 |

75 |

|

80 |

250 |

111 |

85 |

|

95 |

275 |

138 |

95 |

|

120 |

350 |

180 |

105 |

BMC Seal of Double-wall Corrugated Box with Edge Crush Test(ECT):

|

Gross Weight(LBS) Max Weight of Box and Products |

Edge Crush Test(LBS/INCH) (ECT) |

Size Limit(INCH) (L + W + H) |

|

80 |

42 |

85 |

|

100 |

48 |

95 |

|

120 |

51 |

105 |

|

140 |

61 |

110 |

|

160 |

71 |

115 |

|

180 |

82 |

120 |

BMC Seal of Double-wall Corrugated Box with Mullen Test(Bursting Test):

|

Gross Weight(LBS) Max Weight of Box and Products |

Bursting Test(LBS PER SQ INCH) Mullen Test |

Minimum Combination Weight Facings(LBS PER M SQ FT) |

Size Limit(INCH) (L + W + H) |

|

80 |

200 |

92 |

85 |

|

100 |

275 |

110 |

95 |

|

120 |

350 |

126 |

105 |

|

140 |

400 |

180 |

110 |

|

160 |

500 |

222 |

115 |

|

180 |

600 |

270 |

120 |

BMC Seal of Triple-wall Corrugated Box with Edge Crush Test(ECT):

|

Gross Weight(LBS) Max Weight of Box and Products |

Edge Crush Test(LBS/INCH) (ECT) |

Size Limit(INCH) (L + W + H) |

|

240 |

67 |

110 |

|

260 |

80 |

115 |

|

280 |

90 |

120 |

|

300 |

112 |

125 |

BMC Seal of Triple-wall Corrugated Box with Mullen Test(Bursting Test):

|

Gross Weight(LBS) Max Weight of Box and Products |

Bursting Test(LBS PER SQ INCH) Mullen Test |

Minimum Combination Weight Facings(LBS PER M SQ FT) |

Size Limit(INCH) (L + W + H) |

|

240 |

700 |

168 |

110 |

|

260 |

900 |

222 |

115 |

|

280 |

1100 |

264 |

120 |

|

300 |

1300 |

360 |

125 |

BMC Seal of Solid Fiberboard Box with Mullen Test(Bursting Test):

|

Gross Weight(LBS) Max Weight of Box and Products |

Bursting Test(LBS PER SQ INCH) Mullen Test |

Size Limit(INCH) (L + W + H) |

|

20 |

125 |

40 |

|

40 |

175 |

60 |

|

65 |

200 |

75 |

|

90 |

275 |

90 |

|

120 |

350 |

100 |

What tests are used to determine the strength of the corrugated sheet of the corrugated box to make Box Maker's Seal (BMC)?

Below are the tests used to determine the strength of the corrugated sheets of the corrugated box in Box Maker's seal:

- Mullen Test (Burst Test)

- Edge Crush Test

- General Simulation Performance Tests

- ASTM Test, Standard Practice for Performance Testing

When must a box have a Box Maker's Seal (BMC)?

Below are the points where a BMC seal may be used on the box:

- When products are packed in a box, the box must meet quality and safety standards to reduce damage and loss in transit and storage.

- All hazardous products packed in the corrugated box require a BMC seal.

- Products shipped through Rail (UFC) and Motor (NMFTA) freight require a BMC seal on the corrugated box.

- Products requiring extra protection should be packed with a BMC seal in the box.

- Products that require consistent box packaging that aligns with standardized tests and measurements require a BMC seal on the corrugated box.

- Products made of glass, hardware, or fragile items may require a BMC seal on the box.

- All food-related products may need a BMC seal.

- Some shipping carriers may require a BMC seal on the box if the product inside exceeds a certain weight.

- If the government uses the box, it requires a BMC seal.

Which Organizations set the standards for the BMC seal?

In the USA, below are the organizations that certify the standards and regulations of the BMC seal:

- Technical Association of the Pulp & Paper Industry (TAPPI), which measures the paper/sheet quality of the box.

- The International Safe Transit Association (ISTA) measures the box's strength to determine whether it can tolerate different impacts in transit.

- The American Society of Testing and Materials (ASTM) practices uniform evaluation of shipping units' ability to withstand the distribution environment.

- Item 222 of NMFC and Rule 41 of UFC comply with the standard quality of the box.

- The National Motor Freight Classification (NMFC) complies with the freight class used for shipments less than a container.

Which Organizations require a BMC seal on the box for transit?

- The National Motor Freight Traffic Association, Inc. (NMFTA)™. NMFTA has all the standard freight classification codes, which classify everyday items and their shipment class.

- The National Railroad Freight Committee's Uniform Freight Classification (UFC). UFC complies with Rule 41 for fiberboard boxes, which is mentioned in section 2 and section 3 of Rule 41. For detailed information on rules, please visit... SUBJECT, EXCEPT AS OTHERWISE PROVIDED, TO INCREASES IN RATES AND CHARGES AS PROVIDED IN ITEM X8 (railinc.com). (pages 101 to 247).

What significance do Item 222 of NMFC and Rule 41 of UFC have on the BMC seal of the box? What are the standard requirements for a box to have a BMC seal?

Manufacturers and shippers use item 222 of NMFC and Rule 41 of UFC as guidelines to set box quality standards. The box's quality standards specify the type of material used to make it, its weight, and its dimensions. All this information is on the Box Maker's Certificate (BMC), which helps damage customers' claims when they use boxes with BMC seals. Thus, it reduces conflict situations and saves time. It complies with general packaging definitions and specifications for certain commodities.

Item 222 and Rule 41 adhere to the specifications that the manufacturers and shipping carriers must follow regarding the box's definition, strength, type of combined board used to make the box, and tests applied to determine the box's maximum weight capacity.

Thus, Item 222 and Rule 41 play an essential role in the BMC seal on the box.

Why do some manufacturers, shipping carriers, and logistics professionals not just make/use boxes with the BMC seal?

Many manufacturers and shipping carriers prefer to use boxes without BMC seals unless required by government law for product packaging or if the product demands using a box with a BMC seal because of its fragility or any other reason.

They prefer boxes that fit the product perfectly so there is no damage in transit instead of boxes with a BMC seal. They do not use BMC seal-certified boxes to avoid conflicts regarding box strength and durability between manufacturers and customers. Instead, they prefer using the correct box size and strength to reduce liability.

FedEx, UPS, USPS, and DHL don't require their boxes to have a BMC seal.

Manufacturers that make custom boxes or boxes on demand prefer not to seal with BMC certification.

What are the benefits of using BMC seal boxes?

- BMC seal boxes have information about their weight-bearing capacity; thus, the correct BMC seal box can be selected for product packaging. This information minimizes the box breaking in transit mishap just because the box could not bear the product's weight.

- BMC seal boxes work best for hazardous product packaging, thus making sure that the box will protect the dangerous content in transit.

- BMC seal boxes have information on the type of corrugated sheets used to make them, which can help customers select the correct box for their products.

- BMc seal boxes also have dimensions details, which help the customer choose the right box size for the product.

- BMC seal boxes undergo a strength test (Mullen Test or Edge Crush Test), which helps choose the correct product box.

- BMC seal boxes notify that the box meets all the transportation requirements for NMFTA(The National Motor Freight Traffic Association, Inc.) and UFC (The National Railroad Freight Committee's Uniform Freight Classification).

- BMC seal boxes can help the business with lower return rates and higher customer satisfaction.

- The BMC seal-certified box provides essential information that helps customers use the correct box for product protection and reduce damages and losses in transit and storage.

- Customers can select the correct box based on the product weight using a BMC seal on the box. The BMC seal provides the box's strength.

It's essential to know which test is on the BMC seal. A box with a BMC seal with the Mullen test has more weight-bearing capacity than a box with the BMC seal of ECT. Thus, the box selection for BMC seals should depend on the product weight.

Special thanks to Item 222 of the NMFC and Rule 41 of the UFC for their valuable insights into freight classification and packaging standards. We also acknowledge The National Motor Freight Traffic Association, Inc. (NMFTA)™ and The National Railroad Freight Committee's Uniform Freight Classification (UFC) for their contributions to maintaining quality and consistency in the industry. Your work ensures safer, more efficient freight transportation for businesses and customers.