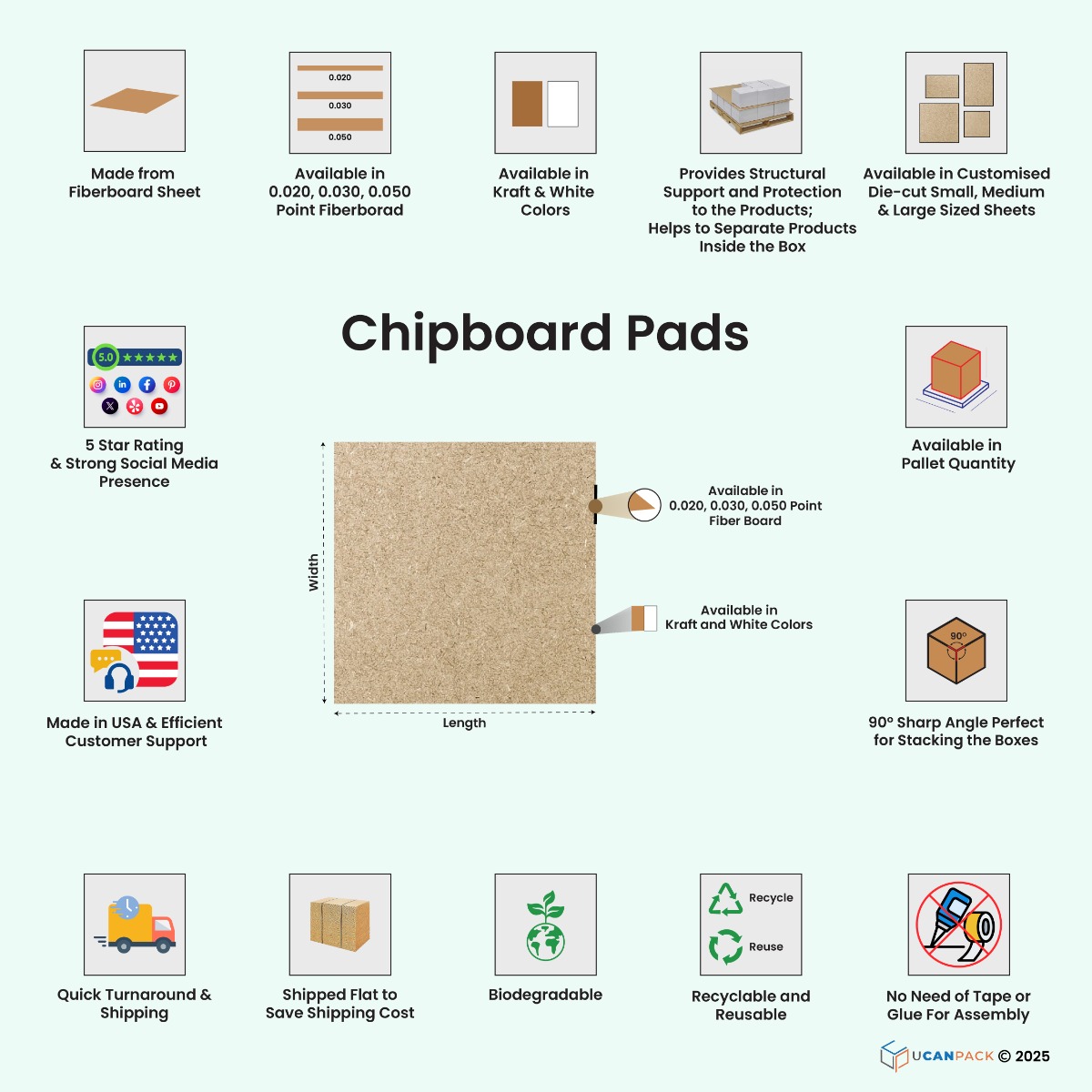

Chipboard Pads - Fiberboard and Corrugated Layer Pads

- Made from compressed layers of recycled paper fibers, they provide excellent protection to packages.

- They are versatile and can be used to create dividers or as a protective layer for fragile items.

- As an eco-friendly product, chipboard layer pads help promote sustainable businesses.

- With easy customization, the chipboard pads can be procured in any size or shape as well as can be printed with your company logo or names.

| Case quantity |

| |||||||

| 100 /Case |

| ||||||

| 1125 /Case |

| ||||||

| 100 /Case |

| ||||||

| 675 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 1050 /Case |

| ||||||

| 800 /Case |

| ||||||

| 100 /Case |

| ||||||

| 470 /Case |

| ||||||

| 750 /Case |

| ||||||

| 960 /Case |

| ||||||

| 960 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 640 /Case |

| ||||||

| 825 /Case |

| ||||||

| 490 /Case |

| ||||||

| 625 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 100 /Case |

| ||||||

| 575 /Case |

| ||||||

| 760 /Case |

| ||||||

| 530 /Case |

| ||||||

| 460 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 100 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 280 /Case |

| ||||||

| 350 /Case |

| ||||||

| 50 /Case |

| ||||||

| 50 /Case |

| ||||||

| 100 /Case |

| ||||||

| 375 /Case |

| ||||||

| 480 /Case |

| ||||||

| 100 /Case |

| ||||||

| 50 /Case |

| ||||||

| 420 /Case |

| ||||||

| 50 /Case |

| ||||||

Chipboard Pads: A Versatile Solution for Packaging Needs

With online shopping being the trend, it is essential for any e-commerce business to make sure that their customers receive products in perfect condition. That’s where UCanPack’s chipboard layer pads enter the chat. Also known as chipboard sheets or cardboard pads, they help businesses deliver their products in an unspoiled condition. They are best for ensuring that products such as electronic items, cosmetics, and other fragile goods remain intact during transit. Chipboard layer pads are also used to add a protective layer over items to prevent them from scratches or creases. Let’s explore some factors that make our chipboard pads a decent choice for your packaging needs.

Features

These pads make the packaging sturdier and also keeps the items intact against impacts, vibrations, or compression during the shipment process.

Chipboard layer pads cater to the needs of a wide range of shipments and can also be used to create dividers within a package to keep the contents from crashing into one another.

A very customizable product, chipboard pads offer a space that can be printed with company logos and names to improve brand visibility.

They are made from recyclable material and help our customers reach their sustainability goals.

Still Can’t Decide?

Need some more help to decide which one to pick? Don’t worry as our packaging experts are here to help you. Call us at (201)-975-6272 or send us an email and we’ll make sure all your queries are resolved.