What are 200# and 32 ECT Boxes?

Introduction:

Choosing the right packaging is essential when shipping your goods as it protects your goods and ensures that they reach their destination in good condition. Box sizes of 200# and 32 ECT are two common box types used for shipping. Although they may look similar at first glance, there are some important differences that affect functionality. To help you choose the package that best suits your needs, this blog post will explain the differences between these two types of boxes, including their rating system and the pros and cons of each.

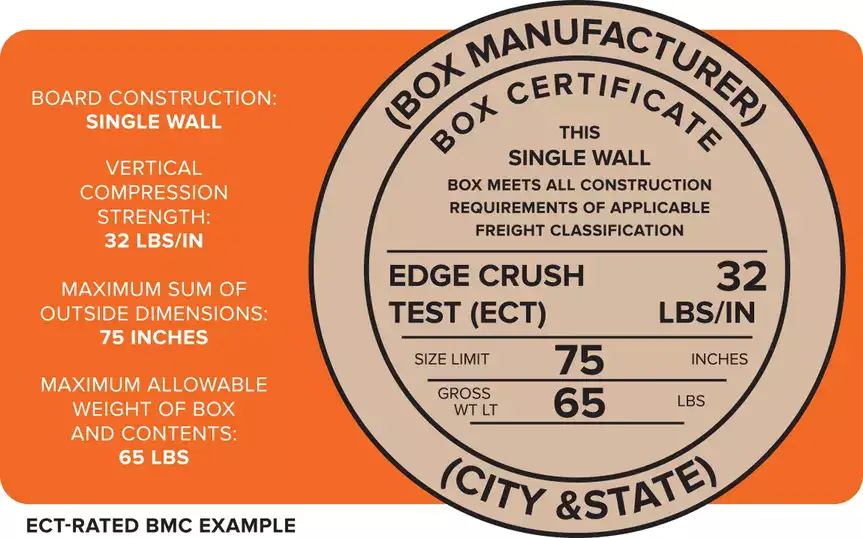

A "32 ECT" box is a corrugated cardboard box that has been tested and found to have an "edge crush test" strength of 32 pounds per inch of edge. This implies that the box can withstand up to 32 pounds of weight on each inch of its edges without being pulverized or collapsing.

While a "200#" box is also a corrugated cardboard box, but its strength is measured differently. The "200#" rating refers to the "burst strength" of the box, which is the sum of weight it can withstand some time recently it bursts or breaks. A box with a "200#" rating can withstand up to 200 pounds per square inch (PSI) of weight some time recently bursting.

What are 200# and 32 ECT Boxes?

When it comes to shipping and packaging, there are many different types of boxes available to choose from. Two common options are 200# boxes and 32 ECT boxes.

The box is stronger and can support greater weight when the PSI is higher. For instance, a 200# box can support up to 200 pounds per square inch. Several carriers utilise this rating system, which is well-known in the shipping industry, to determine if a cargo can resist the rigours of shipment.

200# boxes are made from a combination of materials, including cardboard and fibreboard, and are designed to be durable and sturdy. They are often used for shipping heavier items that require extra protection, such as furniture, electronics or machinery.

So where are these boxes used anyway? Firstly. We have to go through on what these 200# or 32ECT stuff mean anyway?

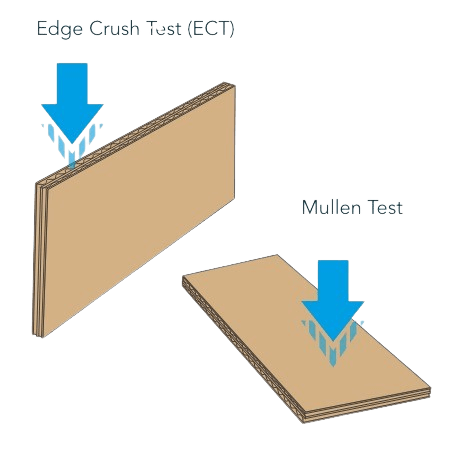

Edge Crush Test

Edge Crush Test, also known as ECT, is a testing procedure used to assess the durability of a box's edges. The amount of force that an ECT box can withstand before collapsing determines how highly rated it is. A box with an ECT 32 rating can withstand an edge crush force of up to 32 pounds per inch. Corrugated fibreboard, a type of material composed of a fluted layer sandwiched between two flat linerboard layers, is the material used to make ECT boxes.

Okay, and these 32 ECT Boxes are?

32 ECT boxes are a specific type of ECT box that are rated at 32 pounds per inch of edge crush. These boxes are suitable for a wide range of applications and are commonly used in industries such as e-commerce, retail, and food and beverage.

The versatility of 32 ECT boxes is one of its key benefits. They can be used to ship a variety of goods, such as electronics, books, and clothing. Furthermore, 32 ECT are lightweight and simple to stack and store, making them a great choice for businesses that have limited storage space.

Another advantage of 32 ECT boxes is their cost-effectiveness. Because they use less material than other types of boxes, they are less expensive to produce and ship. This makes them an ideal option for businesses that want to save on packaging costs.

However, one of the main disadvantages of 32 ECT boxes is their strength. Because they are rated based on their edge crush strength, they may not be suitable for heavy or fragile items. Also, they may not be suitable for long-distance shipping because they may not be able to withstand the stress and pressure of being transported over long distances.

Cool, and what do you mean by 200#?

The "200#" in 200# boxes refers to the Mullen burst test rating that the box has received. The Mullen test is a test that measures the strength and durability of corrugated cardboard boxes by applying pressure to the box until it bursts. The test determines the amount of pressure that a box can withstand before it ruptures.

In the case of 200# boxes, the box has been rated to withstand a pressure of up to 200 pounds per square inch (PSI) before bursting. This means that the box is strong enough to protect heavy and bulky items during shipping and handling.

The Mullen test is just one of several tests that are used to measure the strength of corrugated cardboard boxes. Another common test is the Edge Crush Test (ECT), which measures the stacking strength of a box by assessing its resistance to crushing when it's stacked underweight.

While both Mullen rated and ECT rated boxes can be strong and reliable packaging options, they have different characteristics and are suitable for different applications. It's important to understand the specific needs of your product and business when selecting the right type of box for your packaging needs.

Mullen Test

200# boxes are corrugated cardboard boxes that are rated for strength using the Mullen test. The Mullen test measures a box's ability to resist external pressure and puncture, and the 200# rating means that the box can withstand up to 200 pounds per square inch of pressure without puncturing or breaking.

200# boxes are a popular choice for packaging heavy items that require extra protection during shipping. They are often used for items like machinery, equipment, and appliances, as well as fragile items like glassware or electronics.

One of the advantages of using 200# boxes is their strength and durability. They are designed to provide excellent protection for their contents, even under the most challenging shipping conditions. They are also available in a variety of sizes and styles, making it easy to find the right box for any application.

Another advantage of 200# boxes is that they are widely recognized in the shipping industry as a reliable choice for packaging heavy or fragile items. This means that they are often accepted by carriers like FedEx and UPS without the need for additional packaging or labelling.

At the same time, 200# boxes may not be necessary for all packaging applications. For example, if you are shipping relatively light items that don't require as much protection, a lighter weight box like a 32 ECT box may be sufficient.

Overall, 200# boxes are a strong and reliable choice for packaging heavy or fragile items, but it's important to consider the specific needs of your product and business when choosing a packaging solution.

Where are these boxes used?

When it comes to selecting the right type of box for your shipping and packaging needs, it's important to consider the specific requirements of your products. 200# boxes and 32 ECT boxes are two common options used in a variety of industries.

Where are 200# Boxes used?

200# boxes are commonly used in a variety of industries, including manufacturing, automotive, and retail. These boxes are ideal for shipping heavy-duty and fragile items, such as automotive parts, machinery, and glass products. The Mullen test rating system used to measure the strength of 200# boxes makes them a reliable option for shipping items that require extra protection during transport.

In the manufacturing industry, 200# boxes are often used to ship heavy-duty components, such as metal parts, machinery, and equipment. These boxes are strong enough to protect these items from damage during transport and can withstand the stress and pressure of being shipped over long distances.

In the automotive industry, 200# boxes are used to ship parts, such as engines, transmissions, and exhaust systems. These parts are often heavy and require extra protection during shipping to ensure they arrive at their destination undamaged.

Retailers also use 200# boxes to ship fragile items, such as glass products, ceramics, and electronics. These items require extra protection during transport to prevent damage and ensure they arrive at their destination in perfect condition.

Where are 32 ECT Boxes used?

A number of businesses, including e-commerce, food & beverage, and consumer goods, frequently use 32 ECT boxes. These boxes are a popular option for companies looking to lower their packing expenses and environmental impact because they are lightweight, economical, and green.

In the e-commerce industry, 32 ECT boxes are often used to ship small and light items, such as clothing, books, and electronics. These boxes are strong enough to protect these items during transport and are often used for shipping items directly to consumers.

In the food and beverage industry, 32 ECT boxes are used to ship food and beverage products, such as packaged snacks, beverages, and canned goods. These boxes are suitable for shipping these items because they are lightweight and can be easily stacked, allowing for efficient storage and transport.

The consumer goods industry uses 32 ECT boxes to ship a wide variety of products, including cosmetics, toys, and household items. These boxes are lightweight and inexpensive, making them suitable for businesses looking to save on packaging costs and reduce their environmental impact.

200 vs 32 ECT: Pros and Con

200# Mullen Pros and Cons

Superior strength: 200# boxes are designed to be strong and durable, making them an excellent choice for heavier items or items that require extra protection during shipping. They can withstand higher levels of pressure and are less likely to collapse or rupture during transport.

Available in larger sizes: 200# boxes are often available in larger sizes, making them a good choice for shipping bigger items.

Industry standard: The Mullen Test is widely recognized in the shipping industry, making 200# boxes a reliable choice for businesses that want to ensure the safe delivery of their products.

Cons of 200# Boxes:

Heavier: 200# boxes are heavier than 32 ECT boxes, which can add to the shipping costs. The extra weight can also make them more difficult to handle and manoeuvre during the packaging process.

More expensive: 200# boxes are more expensive than 32 ECT boxes due to their increased strength and durability. This can add up for businesses that need to purchase large quantities of boxes.

Less environmentally friendly: 200# boxes require more material to produce, making them less environmentally friendly than 32 ECT boxes. Businesses that prioritize sustainability may prefer to use alternative packaging materials or opt for 32 ECT boxes instead.

A 32 ECT box can withstand a maximum weight of 32 pounds per inch of width, making it a suitable choice for shipping lighter items or items that don't require extra protection. 32 ECT boxes are made from a single layer of corrugated cardboard and are designed to be lightweight and easy to handle.

32 ECT boxes are a lightweight and cost-effective packaging option that are rated using the Edge Crush Test (ECT). The ECT measures the stacking strength of a box, which is its ability to resist crushing from external pressure. This rating system is expressed in pounds per inch of width (lb/in), and the higher the rating, the stronger the box.

32 ECT Pros and Cons

Lightweight: 32 ECT boxes are much lighter than 200# boxes, making them an excellent choice for shipping lighter items or items that don't require extra protection. The lower weight can also reduce shipping costs.

Cost-effective: 32 ECT boxes are less expensive than 200# boxes, making them a good choice for businesses that need to save on packaging costs.

Environmentally friendly: 32 ECT boxes require less material to produce, making them more environmentally friendly than 200# boxes.

Cons of 32 ECT Boxes:

Not as strong: 32 ECT boxes are not as strong as 200# boxes, making them less suitable for heavier items or items that require extra protection during shipping. They may not withstand the same levels of pressure and are more likely to collapse or rupture during transport.

Limited size options: 32 ECT boxes are typically available in smaller sizes, making them less suitable for shipping larger items.

Which One is Right for You?

Deciding between 200# and 32 ECT boxes ultimately depends on your specific packaging needs. Both types of boxes have their pros and cons, and it's important to consider these factors when selecting the right packaging solution for your business.

If you're shipping heavier items or items that require extra protection during shipping, 200# boxes may be the better choice. They are stronger and more durable than 32 ECT boxes and can withstand higher levels of pressure. However, 200# boxes are more expensive and heavier, which can add to your packaging and shipping costs.

If you're shipping lighter items that don't require extra protection, 32 ECT boxes may be the better choice. They are lightweight, cost-effective, and environmentally friendly, making them a good choice for businesses that want to save on packaging costs and reduce their environmental impact. However, 32 ECT boxes are not as strong as 200# boxes and may not be suitable for heavier items or items that require extra protection during shipping.

At a glance:

|

32 ECT Boxes |

200# Boxes |

|

|

Lightweight and easy to handle |

High burst strength, making them ideal for heavy or fragile items |

|

|

Pros |

Affordable price point |

More flexible than 32 ECT boxes, allowing for packing of irregularly-shaped items |

|

Good stacking strength, making them ideal for smaller, lightweight items |

Sturdier and more durable than 32 ECT boxes |

|

|

May not be suitable for heavy or delicate items |

More expensive than 32 ECT boxes |

|

|

Cons |

Lower burst strength compared to 200# boxes |

Heavier and bulkier, making them more challenging to handle and transport |

|

Limited flexibility, which can make it challenging to pack irregularly-shaped items |

Lower stacking strength compared to 32 ECT boxes, making them less suitable for lighter items |

Some in depth analysis:

While both are made from corrugated cardboard and designed to protect products during shipping, they have distinct differences in terms of their strength, weight, and price. In this article, we will take an in-depth look at the pros and cons of 200 vs 32 ECT boxes, with a focus on their price, stacking strength, and heaviness. By the end of this article, you will have a better understanding of which type of box is best suited for your specific shipping needs.

Price:

One of the main advantages of the 32 ECT box is its cost effectiveness. They are generally less expensive than 200# Mullen certified boxes because they are made from lighter materials and require less fibre to manufacture. This makes it popular with companies that ship lightweight products in high volumes.

On the other hand, 200# Mullen rated boxes are generally more expensive due to their higher quality and durability. They are made from heavier materials and require more fibre to manufacture, increasing their cost. However, they are more reliable and better protect heavy or fragile items in transit, making them suitable for businesses that need to ensure that their products reach their destination undamaged.

Stacking Strength:

Another important consideration when choosing between 32 ECT boxes and 200# Mullen rated boxes is stacking strength. Stacking strength refers to a box's ability to withstand the weight of other boxes stacked on top of it during transport or storage.

32 ECT boxes have limited stacking strength and may not be suitable for heavy items or items that require extra protection during transport. Perfect for stacking light to medium weight items such as clothing and paper products.

200# Mullen rated boxes, on the other hand, offer high stacking strength due to their thicker and heavier material. They are ideal for heavy, fragile, or high-value items that need to be stacked during transport or storage. They are also a good choice for international shipping, where boxes may be stacked on top of each other for extended periods of time.

Heaviness:

The weight of the boxes themselves is another consideration when choosing between 32 ECT boxes and 200# Mullen rated boxes. 32 ECT boxes are lightweight and easy to handle, making them a good choice for businesses that need to ship large volumes of products.

200# Mullen rated crates, on the other hand, are heavy and bulky to store. This can make handling difficult and increase shipping costs due to weight. However, their higher weight makes them more durable and better protects heavy or fragile items during transport.

Ultimately, the choice between 32 ECT boxes and 200# Mullen rated boxes will depend on the specific needs of your business and products. It's important to consider factors such as price, stacking strength, and heaviness when making your decision. If you're unsure which type of box is best for your needs, a packaging specialist can help you evaluate your options and select the right box for your products.

UCanPack's Packaging Services

UCanPack offers a variety of packaging solutions to meet the unique needs of your business. We understand that choosing the right packaging solution can be a challenge, so we offer expert advice and guidance to help you choose the right packaging for your product.

Our packaging solutions include both 200# and 32 ECT boxes and a variety of options to meet your exact needs. Our team of packaging experts can help you determine the right packaging solution for your business based on product type, weight, size, and destination.

We also offer custom packaging solutions to give our customers a unique brand packaging experience. Our team of designers can help you create custom packaging that showcases your brand and ensures safe delivery of your products.

Our 200 lb. test boxes, provide more strength and protection than 32 ECT box and have 50% greater bursting strength than 32 ECT boxes. Greater bursting strength means fewer crushed and damaged boxes during shipping.

A box with a bursting strength of 200 lb can withstand a force of 200 pounds per square inch (psi) without breaking open. 32 ECT, on the other hand, is a measure of the stacking strength of the box, which refers to the amount of weight the box can hold without collapsing when stacked on top of other boxes.

A box with an ECT rating of 32 can withstand a load of 32 pounds per inch of width without collapsing. The 32 ECT rating is a lower rating and is typically used for lighter-weight items such as clothing, books, and small electronics. These boxes are less expensive and are a good choice if you are shipping items that are not heavy or fragile. They are also easier to handle and can be stacked without crushing the items inside.

Apart from Mullen & ECT here are two other common tests for shipping box strength:

SCT: Short Span Compression Test is a type of compression test that measures the compressive strength of corrugated cardboard in the short span direction. The short span is the distance between the flutes of the corrugated cardboard, which is perpendicular to the direction of the flutes.

BCT: Box Compression Test: This test measures the amount of force required to crush a corrugated box when it is stacked. The box is placed on a compression testing machine and subjected to vertical pressure until it deforms or collapses. The force required to achieve deformation or collapse is recorded, and this is the box's box compression strength.

Results can be influenced by various factors related to the paperboard, corrugated board construction, moisture content, sample size, and shape, test conditions, and testing machine.

Conclusion

When it comes to packaging, selecting the right solution is essential for the safe and efficient delivery of your products. 200# and 32 ECT boxes are two popular options in the shipping industry, each with their own unique features and benefits.

While 200# boxes are stronger and more durable, they are also more expensive and heavier, making them less suitable for lighter items. 32 ECT boxes are lightweight and cost-effective, making them a good choice for lighter items, but may not be suitable for heavier items.