Branded Packaging on a Budget: Custom Printed Boxes vs Stickers vs Branded Tape

Introduction: Branding Where Margins Matter

These days, people don’t just expect a product to show up. They expect it to show up with personality. Custom packaging designs, clean visuals, branded elements. It all adds up to how the product feels before it is even used.

And it’s not just a high-end expectation. A recent Store Brands report found that Gen Z places more importance on packaging design and labeling than any other age group.That may sound like a demographic footnote, but it reflects a broader shift. Design is no longer decoration. It is trust. And trust doesn’t have to come with a premium price tag.

So, how do you brand packaging when you're not working with luxury margins? That’s where strategy steps in. No need to customize everything. You just need to brand the right layer: box, sticker, or tape. Each option plays a different role depending on how your business runs and how your customer interacts.

That means looking beyond the surface. What does it cost to scale custom printed boxes across multiple SKUs? How long does branded packaging tape hold up across fulfillment zones? When are custom stickers more than a workaround?

This article unpacks all of that. You will get technical comparisons, cost logic, and performance insights that actually match how things move in real warehouses, not just design studios.

Let us get into the mechanics.

Three Branding Methods, One Packaging Layer

Every package has layers. Outer structure, inner contents, sealing components. Branding follows that same logic. It appears in different places, at different points in the shipping flow. Some are built into the box. Others get applied just before the shipment moves out. The decision is not only about cost. It depends on where the branding sits, how visible it is, and what function it is serving.

Start with the surface.

- Custom printed boxes turn the structure itself into the brand. The visuals are baked into the board. No extra handling, no secondary application. For high-volume SKUs or automated lines, that consistency matters. The box shows up the same way every time. The tradeoff is flexibility. Once printed, it is fixed. Any changes mean new tooling, lead times, and stock.

- Stickers work differently. They are modular, scalable, and easy to update. One sticker can carry a promotion, a QR code, or even batch-level data. They let you work with a neutral box and add brand identity only when necessary. For fast-changing catalogs, pre-orders, or seasonal drops, stickers give more control with less waste.

- Branded tape sits at the very end of the line. It is the last layer that gets applied but actually the first thing someone sees. It stretches across seams and wraps around corners, making the package instantly recognizable without needing a custom box at all. It is fast, universal, and works across shipping methods and materials.

Each method serves a different part of the fulfillment cycle. When chosen with intent, even a single branded layer can carry more weight than a full suite of printed assets.

When Custom Printed Boxes Make Business Sense

Custom printed boxes are not about dressing up a shipment. They are a system decision. If your product lineup stays consistent, and your order volumes repeat month after month, this option can help build structure into your workflow.

You print once. Every packaging box that moves through the line carries the same message, the same compliance marks, the same layout. No label applications. No rechecking batch numbers. No delay in sealing. When the packaging stays fixed, everything else around it moves faster.

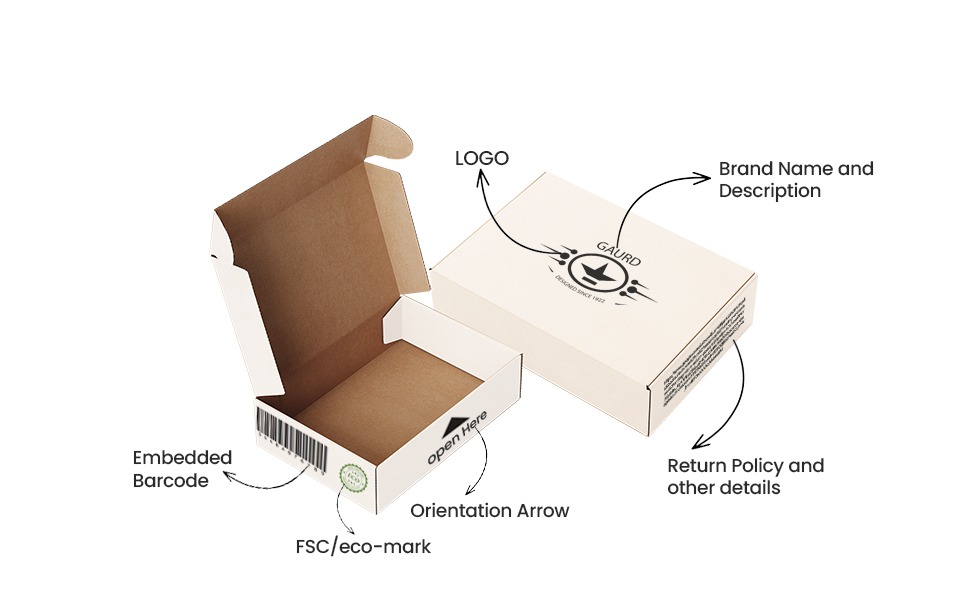

But the real value shows up when you stop treating the box as decoration and start using it for function. Look at this breakdown:

Each panel does something:

- Front-facing branding handles first impressions.

- Side text carries return policies, care instructions, or regulatory details.

- The barcode integrates into the packaging flow.

- Orientation arrows help at the pallet build or dock handoff.

- The eco-mark signals sustainability without adding labels.

Nothing here is cosmetic. It is a design applied where it simplifies the process.

This matters most when boxes are touched by multiple teams—packing, scanning, loading, unpacking. Everyone gets the info they need from a single source. No relabeling. No reprinting. The box tells the story and does the work. If you are curious on how the whole custom printing boxes process works, you can check out this blog. From sketch to ship, it depicts the entire journey of a custom printed box.

Additionally, when you pair that with eco friendly custom printed boxes, it carries the message further. You do not need extra materials to show that your packaging aligns with sustainability goals. It is printed right into the fiber, with no coatings or plastic barriers to slow down recycling.

When Stickers Do More Than Just Save Cost

Stickers are often seen as a compromise. But in setups where flexibility matters more than fixed tooling, they can carry more weight than expected. They adapt fast, cost little to store, and don’t lock you into a single box design.

Let’s say you ship ten different SKUs, all in the same box size. A printed box locks in one message. A sticker lets you rotate messages, switch offers, apply seasonal versions, or even localize shipments, without touching the core packaging supply.

And they are not just branding badges. Stickers can signal tamper resistance when placed across seams. They can act as batch labels or internal handling cues when placed near flaps or corners. They work in fulfillment environments that move fast but still want brand visibility.

Application is low lift. Custom stickers can be printed in small batches, stored flat, and applied either manually or with dispensers. For teams that deal with variety more than volume, this matters.

And when you want something that carries your logo, key info, or even QR-based actions, custom mailing labels for your business from UCanPack give you that flexibility at scale. Printed in batches, easy to apply, and made for speed.

Branded Tape for Function-First Branding

You have probably seen Amazon’s iconic black-on-kraft tape, stretched tight across every packaging box they ship. It is not just a seal anymore. It is a well-thought strategy. That strip of branded tape travels across millions of doorsteps, sorting belts, and freight docks daily, carrying the message long before a customer even cuts it open.

That is the power of branded tapes when used with intent.

One roll can cover every box in your workflow. It works with multiple sizes, formats, and fulfillment speeds. If you are running standard RSCs one day and telescopic cartons the next, the tape still fits. And the branding stays consistent.

It also adds a layer of visibility in transit. Before a label is scanned or a barcode is read, tape gets seen. It becomes part of the delivery signal, especially in busy environments where boxes stack fast and shift quickly.

Of course, there is security in it too. Tape applied across the seam creates a visual check. A cut line, a loose edge, small signals that matter when shipments change hands more than once.

The best part? It doesn’t require redesigning your packaging. Just swap in a printed roll. There are many custom tape options available in materials like paper, masking, and polypropylene finishes. So, you choose what fits your product and shipping method best.

Comparative Matrix: Print vs Stickers vs Tape

Let’s break down how each option performs when mapped against real-world fulfillment needs:

| Feature | Custom Printed Boxes | Custom Stickers | Branded Tape |

| Best Fit | Fixed SKUs, repeat runs | Variable products, promos | Multi-size operations |

| Packing Speed | High (pre-applied) | Moderate (manual application) | High (inline use) |

| Cost Behavior | Scales well at volume | Low upfront, scales flexibly | Balanced across SKUs |

| Storage Simplicity | Bulkier (multiple sizes) | Compact (flat sheets/rolls) | Minimal (single roll fits all) |

| Tamper Visibility | None | Moderate | Strong visual cue |

| Material Flexibility | High (eco-stock available) | Easy to recycle | Options in paper, masking, poly |

Each of these tools brings clarity, control, and consistency, but in different formats. The smart move is choosing based on how your packaging system actually operates.

Final Considerations Before You Ship

Branded packaging plays a role far beyond presentation. It supports how your team packs, how products move through the system, and what the customer sees first. Be it custom printed boxes, logo stickers, or branded tapes, each format serves a specific purpose in your flow.

The key is to align your branding with your process. For businesses that rely on speed, tap into what integrates without delay. For product lines that change often, use tools that adapt fast and stay flexible.

UCanPack offers personalized options across various different formats. They are built for teams that want clarity, control, and consistency in how they ship. Choose based on function, not noise. Packaging works best when it fits the way you already operate.