Packing the Heavyweights: How to Safely Package Heavy or Bulky Items

Introduction

Packaging heavy or bulky items is not a matter of simply upsizing a box. It requires structural precision, material integrity, and logistical foresight. In industrial, manufacturing, and B2B distribution environments, a poorly packaged 80-pound item can cause more than just damage. It can result in rework, injury, or freight non-compliance. When shipping products that exceed standard parcel weight thresholds, packaging must be engineered to withstand not only vertical compression but also lateral impact, flexion, vibration, and stress concentration over time.

In order to reduce product damage and improve handling efficiency, demand for heavy duty shipping boxes and reinforced packaging continues to grow across industrial sectors. According to recent industry analysis, heavy-duty corrugated packaging is seeing rapid adoption in markets such as automotive, electronics, and pharmaceuticals, specifically for applications requiring crush-resistant and puncture-proof materials. This shift reflects a broader movement toward structurally engineered packaging systems capable of withstanding dynamic freight and warehouse conditions.

In this article, we will examine the structural design principles, material choices, and packaging techniques required to ship heavy and oversized products safely. It also addresses practical applications of double wall corrugated and triple wall cardboard boxes, and how companies evaluating the best way to ship heavy items can reduce failure points at the packaging level itself.

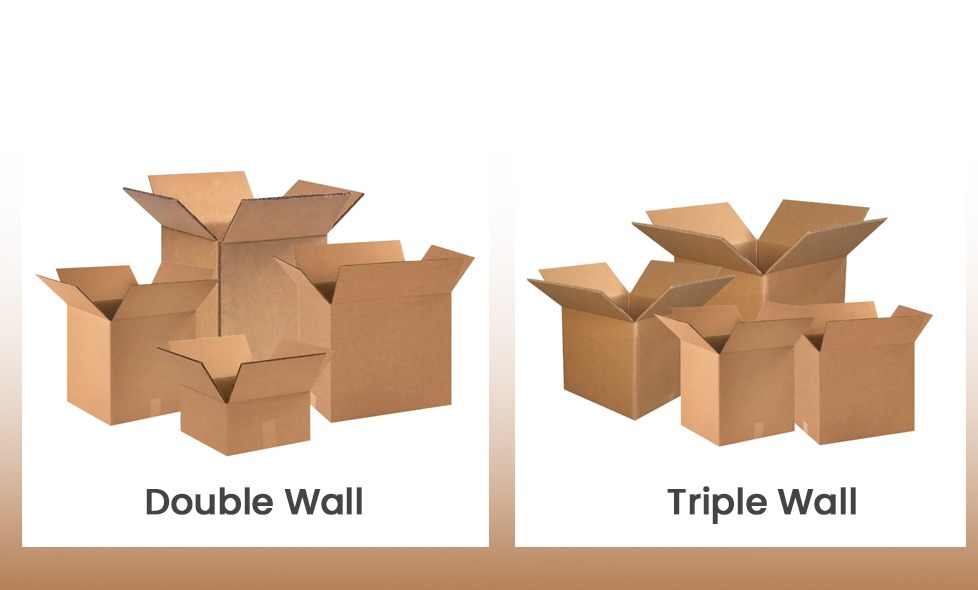

Material Engineering: Double-Wall, Triple-Wall, and Reinforced Packaging

Effective packaging for heavy or bulky items begins with selecting the right material composition, not just in terms of thickness, but in mechanical performance under stress. Standard single-wall corrugated board is insufficient for items exceeding 70 lbs. Instead, structural loads, impact conditions, and carrier handling requirements demand the use of double-wall corrugated, triple-wall cardboard boxes, or other forms of reinforced packaging.

Double-Wall Corrugated

Double-wall board consists of two corrugated mediums and three linerboards, typically arranged in BC flute or AC flute combinations. This construction offers a balance between stacking strength and puncture resistance, making it suitable for a wide range of medium to heavy-duty shipping applications. A double wall corrugated box rated at ECT-51 or higher can typically support items up to 120 lbs, depending on the perimeter and height of the box.

In many industrial applications, double wall corrugated cardboard sheets are also used as inserts or reinforcement layers to stabilize high-mass products within the packaging, particularly when shipping equipment with uneven weight distribution or sharp contact points.

Triple-Wall Cardboard Boxes

For heavier freight, triple wall cardboard boxes offer significant advantages. With three corrugated mediums and four linerboards, they function as a lightweight alternative to wood crates. Common flute combinations such as AAA or BAC provide extremely high Box Compression Test (BCT) values and excellent rigidity across all axes. A heavy duty triple wall cardboard box is typically rated to handle up to 300 lbs or more and is ideal for products with concentrated mass, such as electric motors, castings, or stacked metal components.

These boxes are also better suited to environments where load-bearing consistency is critical, such as pallet stacking, overseas freight, or automated warehousing systems.

Reinforced Packaging Beyond the Walls

Wall strength alone is not enough. Reinforced packaging includes internal and external elements such as:

- Die-cut load-bearing inserts made from high-density fiberboard or engineered pulp

- Corner posts and cradle channels to redistribute load and minimize shear

- Skid plates or laminated pads to prevent puncture or sag at contact points

These reinforcements not only preserve the structural integrity of the box but also protect the product from transit damage caused by vibration, tilt, or drop impact.

Structural Weak Points and Load Failure Modes

Even the strongest box can fail if its weak points aren’t addressed during design. Once weight crosses the 70 lb threshold, forces like shear, flexion, and torque don’t just show up. They start dictating how the packaging behaves in real transit conditions.

A heavy product shifts, compresses, tilts, and in some cases, deforms the packaging from the inside out. This is why so many packaging failures happen not because the box was not strong, but because it was not built to counteract movement.

- Shear stress occurs when the internal load slides or tilts, pushing diagonally across box walls.

- Flexion happens when long or uneven items sag under their own weight, often bowing side panels.

- Torque failure can arise when off-center mass applies rotational pressure on corners and seams, especially during forklift turns or conveyor drops.

To mitigate this, structural reinforcements must align with the direction of expected load movement, not just the weight rating. For example, full-length fiberboard runners, corner braces, and crosswise inserts reduce flexion and stop internal sag. Even something as simple as increasing glue area at box seams can significantly reduce seam rupture under shear.

When you understand how load failure actually starts, packaging becomes less about resistance and more about smart redirection of force.

Cushioning Strategies for High-Mass Items

When you are packing something heavy, it doesn’t just sit there. It leans into corners. It settles during transit. It tries to move with every forklift turn or conveyor stop. So even if the box looks solid, what happens inside matters just as much.

This is where cushioning becomes more than just padding. It keeps weight from shifting. It spreads pressure. It creates stability around the product, so the load moves like a unit instead of fighting its own packaging.

For most heavy-duty setups, it starts with the base. Foam sheets give you a steady foundation and absorb shock from below. UCanPack’s Foam & Cushioning materials are easy to cut, layer, and press-fit inside larger formats like double wall or triple wall boxes.

Around the sides, especially for uneven or rounded parts, Bubble Roll & Wrap can fill the gaps. It keeps things from bumping around during transport and protects contact points that do not sit flat.

And if you’ve got sharp corners, dense loads, or vertical stacking pressure, Heavy Duty Edge Protectors can make a difference—not just outside the box, but even as internal spacers. They hold the shape and keep the structure from folding under stress.

The trick is to think in zones. What’s protecting the bottom? What’s blocking side movement? What’s keeping the top from collapsing during storage? If you can answer those three, the packaging will hold up, and the product will arrive the way it left.

Which Cushioning Material Works Best for Heavy Shipments?

Here is a table to better depict which cushioning material works best for heavy shipments:

| Material | Best Used For | Compression Resistance | Placement in Box | Reusability |

|---|---|---|---|---|

| Foam Sheets | Base support, flat surfaces, heavy loads | High | Bottom or full lining | Moderate |

| Bubble Roll & Wrap | Curved edges, surface cushioning | Medium | Side gaps and corners | Low |

| Molded Foam or Padded Forms | Irregular shapes, fragile components | Very High | Fully encasing product | Low |

| Corrugated Pads | Load spreaders, under pallets | Medium | Bottom only | High |

| Heavy Duty Edge Protectors | Corner stability, stacking pressure | Very High | Box corners (in/out) | High |

Carrier-Specific Constraints: Parcel vs Freight

So the box is packed, sealed, and reinforced. Now comes the part most teams overlook until it is too late: handing it off to a carrier.

Carriers care less about what is in the box and more about what the box does to their system. A parcel facility wants packages that ride belts, clear scanners, and drop cleanly into bins. A freight dock wants units that stack tight, shift minimally, and survive bumps from every side.

Here is where the split happens.

Parcel carriers—think ground or express—treat anything over 50 pounds with extra handling rules. Oversize fees kick in. Dimensional weight pricing applies in most cases, even when the box doesn’t look oversized. Some hubs assign special routing or require heavy-load labels. If the box flexes, catches, or pops open under motion, it is getting flagged. That means delays or added fees before it even reaches the truck.

Freight carriers care more about pallet footprint, vertical stacking limits, and shift behavior. They scan for unstable tops, soft sides, or lean. If the unit doesn’t hold its shape during forklift loading, it risks being set aside or repacked. That adds time, breaks chain of custody, and pulls the shipment out of flow.

The handoff point decides the constraints. A box moving through parcel hubs needs clean seams, compact dimensions, and reinforced corners. A unit moving through LTL freight networks benefits from tight wrapping, rigid load alignment, and pallet compatibility.

Companies trying to find the best way to ship large heavy items often start at the wrong end. You don’t figure that out at the dock. You figure it out by mapping how your box moves through their system.

Before you choose a carrier, walk the box through their world. How does it roll? How does it stack? What happens when it meets a belt, a cage, or a pallet jack? That’s where the cost either stays flat or starts climbing.

The Final Move in Packing the Heavyweights

Before the forklift arrives, everything must stay aligned. The seams need to stay shut. The weight should stay centered. The product must sit exactly where it was placed when the box was sealed.

At this heavy scale, the packaging does not just carry the product. It carries the responsibility for what happens next. Each layer, from the bottom pad to the outer wrap, has one job: keep the load intact, even when the route changes or the stacking gets tight.

No need to stack materials just for the sake of it. What works is structure, not excess. A box that holds shape, resists strain, and matches the product’s footprint becomes the foundation for smoother handling.

Teams looking for consistency often start with strong materials, but the real edge comes from building a setup that fits the operation. UCanPack supports that with heavy duty shipping boxes, structural formats, and packaging supplies that work across parcel and freight systems. For businesses comparing options, this can often become the cheapest way to ship heavy items without compromising the outcome.

Built right, it moves as one unit, clears every checkpoint, and arrives without surprises. That is what every heavyweight shipment deserves.