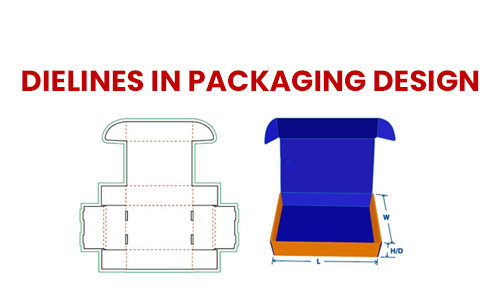

Dielines in Packaging Design

Designing packaging for products is a critical aspect of any business, as it not only protects the product but also plays a vital role in marketing and brand promotion. One of the essential elements of packaging design is the dieline, which is a 2D representation of a package that outlines the structure and layout of the final product.

In this article, we will discuss the importance of dielines in packaging design and how to use them effectively to create functional and visually appealing packaging for your products. We will cover the basics of dielines, including their types, essential elements, and best practices for creating them.

What is a Dieline?

A dieline is a template or blueprint that outlines the structure and dimensions of a package. It serves as a guide for the printer or manufacturer to cut, fold, and assemble the packaging. Dielines are typically created in 2D vector-based software like Adobe Illustrator or CorelDRAW and are provided to the printer or manufacturer as a PDF file.

Types of Dielines:

There are different types of dielines depending on the type of packaging you are creating. Some of the most common types include:

Folding Carton Dielines - These are the most common type of dielines and are used for creating cardboard boxes, such as cereal boxes, shoe boxes, and other similar packages.

Corrugated Box Dielines - Corrugated box & mailer boxes dielines are used for creating shipping boxes and other heavy-duty packages.

Flexible Packaging Dielines - Flexible packaging dielines are used for creating bags, pouches, and other non-rigid packages.

Blister Packaging Dielines - Blister packaging dielines are used for creating clear plastic packaging that encases products like batteries, toys, and electronics.

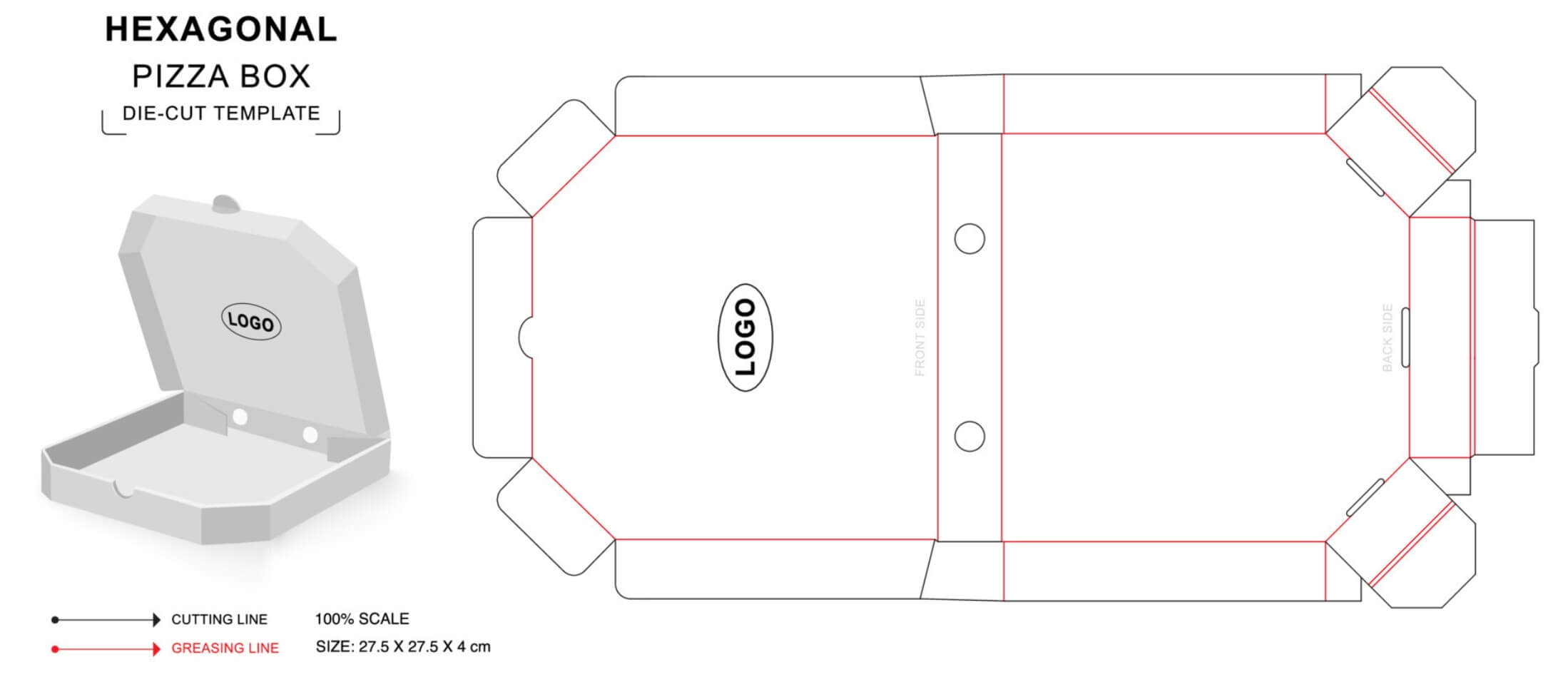

Essential Elements of a Dieline:

A dieline contains several essential elements that are necessary for creating functional and visually appealing packaging. These elements include:

Structural Design - This includes the overall shape and dimensions of the package, such as the width, height, and depth.

Flaps and Folds - Flaps and folds are used to create the structure of the package, and the dieline should indicate where they are located and how they should be folded.

Cut Lines - Cut lines are used to indicate where the package should be cut, and they should be clearly defined on the dieline.

Bleed - Bleed is the area beyond the edge of the dieline where the artwork should extend to ensure that there are no white spaces or borders on the final product.

Safe Zone - The safe zone is the area within the dieline where important elements like text and logos should be placed to avoid being cut off during production.

Creating a Dieline:

Creating a dieline can be a challenging task, especially if you are new to packaging design. However, following these best practices can help you create a functional and visually appealing dieline:

Start with a Template - Starting with a pre-made template can save time and ensure that your dieline is correctly sized and structured.

Determine the Dimensions - Determine the width, height, and depth of the package and ensure that it is large enough to accommodate the product.

Create the Structural Design - Create the basic shape and structure of the package, including the flaps and folds.

Add Cut Lines and Bleed - Add cut lines to indicate where the package should be cut, and add bleed to ensure that there are no white spaces or borders on the final product.

Add the Safe Zone - Add the safe zone to ensure that important elements like text and logos are not cut off during production.

Test the Dieline - Before sending the dieline to the printer or manufacturer, test it by creating a mock-up to ensure that it is functional

Use Vector-Based Software - Use vector-based software like Adobe Illustrator or CorelDRAW to create the dieline. This ensures that the dieline is scalable and can be easily edited if necessary.

Keep it Simple - Keep the dieline simple and easy to understand. Avoid adding unnecessary elements or complicated structures that may confuse the printer or manufacturer.

Get Feedback - Get feedback from the printer or manufacturer to ensure that the dieline is accurate and meets their requirements.

Save the Dieline as a PDF - Save the dieline as a PDF file and ensure that all the necessary elements are included, such as cut lines, bleed, and the safe zone.

Tips for Using Dielines Effectively:

Using dielines effectively can help you create packaging that is both functional and visually appealing. Here are some tips for using dielines effectively:

Consider the Product - Consider the product and its shape and size when creating the dieline. The dieline should be designed to accommodate the product and ensure that it is protected during shipping and handling.

Use High-Quality Artwork - Use high-quality artwork when designing the packaging. The artwork should be in a vector-based format and should be high resolution to ensure that it looks sharp and clear on the final product.

Consider the Printing Method - Consider the printing method that will be used when creating the packaging. Different printing methods may require different types of dielines or artwork, so it is important to consult with the printer or manufacturer to ensure that your dieline and artwork are suitable.

Test the Dieline - Test the dieline by creating a mock-up of the packaging. This will allow you to identify any potential issues with the dieline and make any necessary adjustments before sending it to the printer or manufacturer.

Consider the Branding - Consider the branding when designing the packaging. The packaging should be consistent with the brand's visual identity and should communicate the brand's message and values.

Keep it Simple - Keep the packaging design simple and easy to understand. Avoid adding unnecessary elements or complicated structures that may confuse the customer or detract from the product.

Once you have the dieline its time to do the packaging design. There are two options here:

Doing Your Own Packaging Design:

Deciding whether to do your own packaging design or hire a packaging design agency depends on your business's needs and resources. If you have the time and expertise to design your packaging yourself, it can be a cost-effective option that gives you complete control over the design process. However, if you lack expertise or want to ensure that your packaging is professional and consistent with your brand's vision and values, hiring a packaging design agency may be the best option. While it can be more expensive and time-consuming, it can also be more efficient and result in a design that effectively communicates your brand's message and protects your product.

Pros:

Cost-Effective - Doing your own packaging design can save you money. Hiring a packaging design agency can be expensive, and by designing your packaging yourself, you can avoid those costs.

Control - Doing your own packaging design gives you complete control over the design process. You can ensure that the design aligns with your brand's vision and values and that it accurately represents your product.

Flexibility - Doing your own packaging design allows you to make changes quickly and easily. You can make adjustments to the design without having to wait for a third party to make those changes.

Cons:

Time-Consuming - Designing your packaging yourself can be time-consuming. It can take a significant amount of time to create a design that is both functional and visually appealing.

Limited Expertise - Unless you have experience in packaging design, you may lack the expertise needed to create a design that effectively communicates your brand's message and protects your product.

Lack of Professionalism - If your packaging design is not up to professional standards, it may be perceived as unprofessional and negatively impact your brand's reputation.

Hiring a Packaging Design Agency:

Pros:

Professional Expertise - Hiring a packaging design agency gives you access to professional expertise. These agencies have experience in packaging design and can create designs that effectively communicate your brand's message and protect your product.

Efficiency - Hiring a packaging design agency can save you time. These agencies are equipped with the necessary tools and resources to create a design quickly and efficiently.

Consistency - Hiring a packaging design agency ensures consistency in your brand's visual identity. These agencies are skilled in creating designs that align with your brand's vision and values and ensure that your brand is presented consistently across all packaging.

Cons:

Cost - Hiring a packaging design agency can be expensive. These agencies charge for their services, and the cost can vary depending on the complexity of the project. We at Ucanpack offer free design and graphics consultancy for your packaging project.

Limited Control - Hiring a packaging design agency means giving up some control over the design process. While you can provide input and feedback, the agency will ultimately be responsible for creating the design.

Time-Consuming - Hiring a packaging design agency can also be time-consuming. It can take time to find an agency that is the right fit for your brand and to communicate your brand's vision and values effectively.

Conclusion:

Dielines are an essential element of packaging design, and understanding how to use them effectively can help you create packaging that is both functional and visually appealing. By following the best practices for creating dielines, you can ensure that your packaging is accurately and efficiently produced. Additionally, by considering the product, printing method, branding, and keeping the design simple, you can create packaging that effectively communicates your brand's message and protects your product during shipping and handling.