What’s the Difference Between Mailer Boxes, Shipping Boxes, and Literature Mailers? When Should You Use Each?

Introduction

If you are sourcing packaging at scale, you have likely come across terms like mailer boxes, shipping boxes, and literature mailers. They sound similar. But they are built for very different jobs. Understanding the differences is not just about choosing the right fit. It is about protecting your product, optimizing cost per shipment, and delivering a consistent brand experience.

A study from L.E.K. Consulting shows switching from oversized corrugated boxes to more targeted packaging, like mailers, can reduce freight costs by up to 3%, and packaging material spend by as much as 50%. That kind of efficiency becomes possible when businesses match box type precisely to product size and purpose.

This guide breaks down each box type by structure, function, and best-use scenario. So you can select packaging that works as hard as your business does.

Understanding Box Categories by Design and Use

Different corrugated box types are designed for specific use cases. The material strength, folding style, and closure design all have an effect on how each box performs across different shipping and storage scenarios. Here is a breakdown of the three most common formats you will encounter when sourcing custom packaging.

Mailer Boxes

Mailer boxes are self-locking containers designed for fast fulfillment and polished presentation. They are often used for branded packaging where the unboxing experience matters.

- Structure: Single-piece fold with locking front flaps

- Function: Ideal for lightweight to medium-weight items

Common Uses: Subscription kits, DTC orders, custom mailer box printing

The typical corrugated mailer box is available in multiple mailer box sizes, making it easy to align with various product categories while still managing packaging costs.

Shipping Boxes

Shipping boxes are designed for protection and volume shipping. Designed from stronger board grades, these packaging boxes are a go-to for warehouse operations, B2B fulfillment, and national distribution.

- Structure: Regular slotted container (RSC)

- Function: Supports bulk shipping and higher weight loads

- Common Uses: Industrial packaging, packaging shipping box solutions, inventory distribution

Many businesses choose custom shipping box sizes to match their product SKUs and minimize dimensional weight charges.

Literature Mailers

Literature mailers offer a slim, rigid profile that protects flat products without the bulk of filler. They are efficient to stack and store, and well-suited for low-profile, high-volume items.

- Structure: Fold-over flap with edge protection

- Function: Designed for items like catalogs, manuals, or accessories

- Common Uses: Marketing kits, media packaging, white literature mailers

These are often chosen for wholesale corrugated box orders where product standardization and flat-packing efficiency are important.

You can also use the table below to quickly compare design features, strengths, and common applications across mailer boxes, shipping boxes, and literature mailers:

| Feature / Box Type | Mailer Boxes | Shipping Boxes | Literature Mailers |

| Structure | Self-locking, one-piece fold | Regular Slotted Container (RSC), requires tape | Fold-over design with edge protection |

| Best Use Case | DTC orders, branded kits, custom mailer box | Bulk shipping, B2B distribution, packaging shipping box | Catalogs, manuals, flat items, white literature mailers |

| Board Strength | Lightweight to medium-duty corrugated | Medium to heavy-duty corrugated | Lightweight but rigid |

| Unboxing Experience | High (ideal for mailer box printing) | Moderate | Moderate to low |

| Customization Options | Full-color printing, die-cuts, inserts | Custom sizing, strength, partial print | Limited to sizing, usually plain white or kraft |

| Common Sizes | Multiple mailer box sizes available | Custom shipping box sizes based on product dimensions | Standard flat sizes; fits most paper-format products |

| Fulfillment Speed | Fast to assemble, no tape needed | Slower; requires tape and void fill | Fast; folds quickly, no void fill |

| Storage Efficiency | Flat-packed; moderate stacking efficiency | Bulkier; requires more pallet space | Highly stackable; excellent for warehouse packaging |

Application-Specific Use Cases for Each Box Type

The type of packaging box you choose directly affects your cost per unit, shipping reliability, and how your customer experiences the product. Each packaging format, be it mailer boxes, shipping boxes, or literature mailers, is designed for a specific purpose.

Understanding these use cases helps you make packaging decisions that support both your margins and your brand:

- High-Volume D2C Shipping: If your brand handles hundreds of individual daily orders, especially in fashion, cosmetics, or lifestyle products, mailer boxes streamline fulfillment. Their self-locking design reduces tape usage and improves pack-out speed. For subscription-based models, the unboxing experience becomes part of your product value.

- Bulk Distribution or Mixed-SKU Orders: When shipping inventory to retail partners, handling large B2B orders, or combining multiple SKUs, standard shipping boxes remain the most stable choice. Their stacking strength, compatibility with pallets, and protection against load shift make them essential in logistics-heavy environments.

You can alsocheck out this blog on how standardizing your box sizes can help streamline warehouse operations and reduce long-term costs. - Flat Product Fulfillment: Not all products are bulky or tall. If you regularly ship books, product manuals, certificates, or low-profile tech accessories, literature mailers offer efficient use of space while maintaining structure and presentation. They're widely used for welcome kits, branded stationery, and service-based business onboarding.

- Wholesale Procurement and Storage Planning: Regardless of product type, consistency in packaging dimensions becomes vital when ordering at scale. Businesses often prefer wholesale corrugated boxes that are optimized for rack compatibility and reduce SKU complexity in storage. Aligning packaging choices with shelving and pick-path layouts minimizes handling friction.

Printing Considerations Based on Box Type and Material

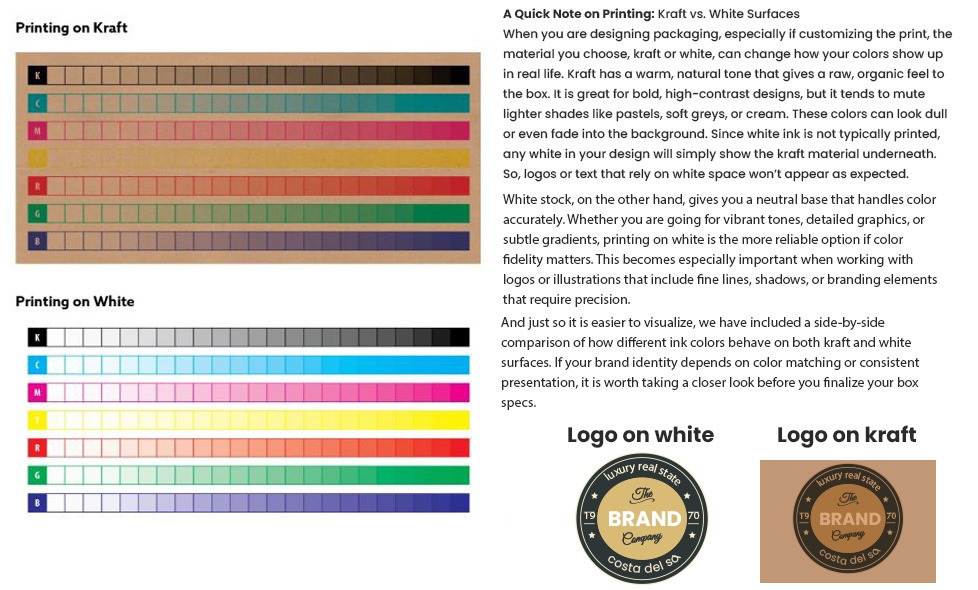

After selecting the appropriate packaging box style based on its application; mailer, shipping box, or literature mailer, the next step is to consider how your branding will appear on the chosen material. That is where material choice and print behavior come into help.

Different box types are commonly available in kraft or white finishes, and each reacts to ink in its own way. For example:

- Mailer boxes, often chosen for direct-to-consumer packaging, are typically printed on kraft. But light colors like pastels, greys, or yellows may not pop unless you use a white base. And if you’re looking for economical, reliable kraft or white mailers that ship flat and hold up in transit, you can check out ourcorrugated indestructo mailers here.

- Literature mailers, used for documents or slim items, are frequently white, making them a better option if your brand depends on accurate color reproduction.

- Shipping boxes are rarely used for visual branding, but if you are printing logos or handling info directly on the box, kraft limits color flexibility.

You can refer to this side-by-side chart to get a sense of how your colors may actually show up in print depending on the box finish:

This is especially important if you are ordering in bulk. A minor mismatch in expectations can carry across thousands of units. Making informed print decisions at the material level helps maintain brand consistency, reduce design revisions, and avoid waste.

Bulk Procurement: What to Know Before Ordering

When you are ordering mailer boxes or shipping cartons in the thousands, you are not just buying packaging, you are locking in decisions that will shape your operations for months. Every choice, from dimensions to board grade, quietly influences cost, space, and fulfillment flow.

For example, if you are sourcing corrugated boxes, ask yourself: How many pallets can your facility realistically handle this quarter? It sounds basic, but overordering just to hit a price break can backfire fast when those pallets start eating into floor space meant for inventory.

Then there is lead time. A five-week turnaround might not hurt now. But what happens when your peak season hits and you are reordering under pressure? Smart bulk buyers stagger their runs or split volume across SKUs to keep flexibility built into the system.

And if you are investing in custom printing, remember: small adjustments can have big consequences at scale. A 1-inch difference in box size affects dimensional weight brackets. A slightly different ink formula can print duller on kraft than on white. That kind of detail matters when you’re shipping thousands of packages with your name on it.

Bulk is not just about volume. It is about predictability. It is about designing a system that keeps working quietly in the background, without surprises, and without inefficiencies slowing you down.

Choosing Based on Handling, Shipping, and Storage

How your packaging performs in the real world depends on more than just size and material. Handling, shipping, and storage all add their own pressure and smart businesses factor in these variables early in the decision-making process.

Handling

A box should feel effortless to work with. That means structural rigidity for stacking, smooth openings if your team packs by hand, and designs that reduce repacking errors. Literature mailers, for instance, are popular in warehouses with high pick-and-pack volume because they are quick to close and do not need tape

Shipping

Packaging must survive the journey, whether it is zone 2 or zone 8. A lightweight mailer box might save cost on dimensional weight, but only if it is properly fitted to the product. Shipping boxes are best when bulk orders or heavier goods are involved. But overbuilding adds cost with no extra value. Matching the box type with the shipping profile is where most cost-efficiency lives.

Storage

A box in storage is still costing you money; floor space, time, and attention. Flat-packed corrugated mailer boxes save room, especially when standardized. Custom sizing is also important. Even a half-inch variation multiplied by 5,000 units can make the difference between needing extra racks or not.

The right box matches how your business operates: how products move, how orders get packed, and how storage space is used. So, it is less about chasing perfection and more about making packaging work with your everyday flow.

Final Considerations for Business Buyers

So by now, you probably have a clearer idea of what each box type actually does. And more importantly, which one fits where in your business.

If you are ordering packaging at scale, here is what is worth thinking through before locking in your next batch:

- Start with your product line. What are you shipping most? Smaller, lighter items might work best with mailer boxes. Bulkier or heavier products? Shipping boxes might make more sense. And those flat, lightweight documents or kits? That’s where literature mailers come in handy.

- Check in with your team. The people packing orders every day know where things slow down. A beautiful box that takes too long to assemble? That’s real friction, and a cost.

- Stick to a core lineup. You do not need 15 box types. Most businesses get 80% of the job done with just a few well-selected sizes. That’s where wholesale corrugated boxes can help streamline your storage and ordering.

- Review what the data says. Look at your past shipments. Which sizes moved fastest? Where did damages happen? Any patterns in returns? Let those insights guide your box choices.

- Think practical, then brand. Yes, branding matters and we love a sharp custom printed mailer box. But it needs to support the customer experience, not slow it down.

As an expert, you probably know, packaging is not that complicated. The more clearly your packaging system matches your product flow, the smoother everything gets.

And if you are ready to explore size options or want to test a few samples, we’ve got you. At ucanpack.com, we manufacture and ship custom corrugated boxes right here in the U.S., with full control over sizing, printing, and order volumes.

Need a white literature mailer with a snug fit? A full-color printed mailer box for DTC delivery? Or standardized shipping boxes that stack like clockwork? You will find them all, ready to customize.