The Hidden Cost of Not Standardizing Box Sizes in Your Warehouse: A Guide for Operations Teams

Introduction

You walk into your warehouse Monday morning with your coffee still steaming. The weekend inventory report sits on your desk like a ticking time bomb. Your warehouse packaging storage system just processed 847 packages using 23 different box sizes.

Sound familiar?

Here is what that report does not tell you. Those 23 box sizes for shipping just cost you $3,200 in wasted shipping fees. Your warehouse staff spent an extra 14 hours deciding which box fits what product. Three pallets of medium boxes sit collecting dust while you rush-ordered small ones on Friday.

Most warehouse managers think more options mean better service. Wrong. More box sizes create a domino effect that hits your bottom line harder than a dropped pallet.

Your warehouse probably faces the same challenges. Boxes scattered across multiple zones. Staff playing guessing games with package dimensions. Shipping costs that make your accountant worried.

The problem runs deeper than you think. Every extra packaging box size multiplies your headaches. Storage space gets fragmented. Staff training becomes complicated. Inventory management turns into a juggling act.

The solution is not at all complicated. But it requires looking beyond the obvious.

This guide digs into something simpler yet more powerful: the packaging boxes themselves. We will show you how the right box standardization strategy can transform your entire packaging operation.

Ready to stop bleeding money on shipping? Let us explore.

The Hidden Costs of Poor Warehouse Packaging Storage

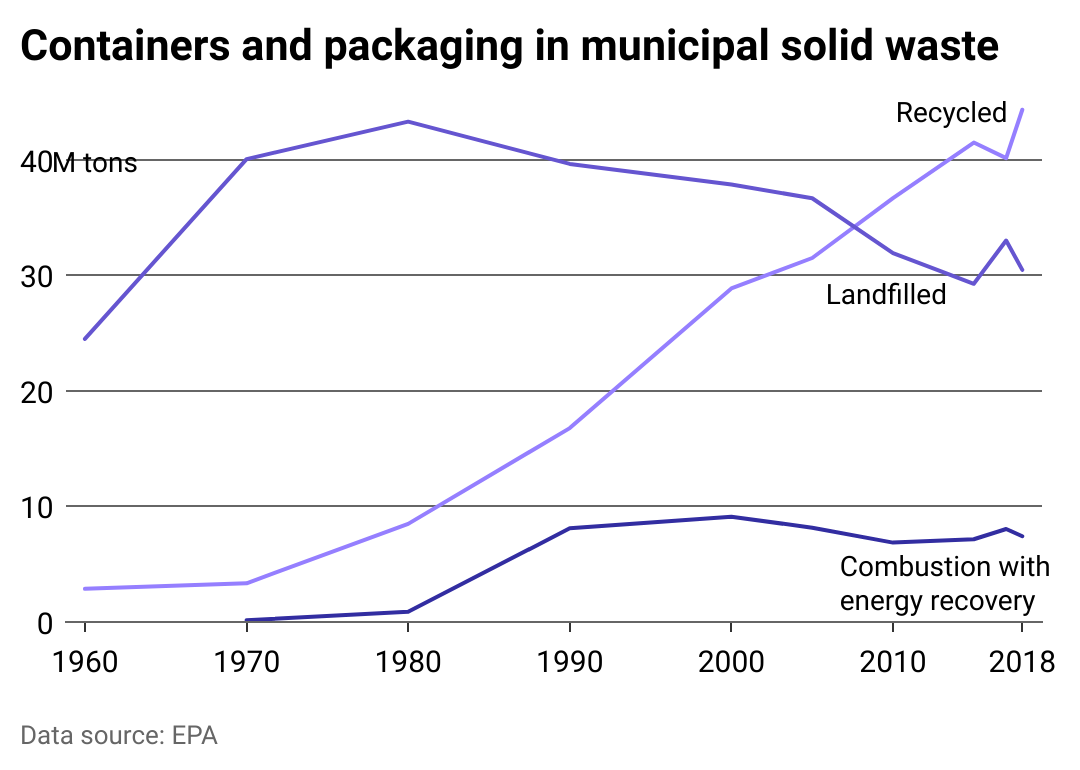

As per a report from the EPA, 82.2 million tons of packaging waste entered the U.S. municipal stream in a single year. That is 28% of all trash.

And much of that waste starts with poor packaging decisions inside the warehouse. Too many box sizes. Inefficient use of space. Shipping costs that get out of control. It is not just a storage problem. It is a supply chain leak rooted in how warehouse packaging is managed on the ground.

Every excess box SKU in your warehouse creates ripple effects:

- Storage Costs Go Up. You need more shelving, more picking lanes, and more buffer stock. That means paying for more square footage.

- Staff Efficiency Goes Down. When there are 20+ box sizes on the wall, workers pause to decide which one to use. That pause kills throughput. Add that up across shifts, and you are losing labor hours daily.

- Dimensional Weight Fees Pile On. Boxes that are too big for the product trigger oversized shipping charges. That one-size-up decision made at the packing table could be costing you 20% to 40% more per order.

- Inventory Forecasting Becomes Guesswork. It is harder to track which sizes are moving and which are collecting dust. You end up overordering some, underordering others, and expediting replacements at a premium.

And then there is waste, the actual waste. Every time you ship a small item in a packaging box that is too large, you are not just losing money. You are contributing to the 82.2 million tons of material that will likely never be recycled, despite the symbol printed on the flap. And if you are wondering how much of that is the result of greenwashed packaging claims, we have broken it down in detail. Read this blog to understand what actually makes a box eco-friendly and how to avoid falling for empty labels.

So, bad warehouse packaging decisions do not show up on a single line item. They bleed into shipping, labor, inventory, returns, and sustainability metrics. That is why operations teams cannot afford to treat box selection as an afterthought

Why Standardizing Box Sizes Improves Shipping Consistency

Standardized box sizes make shipping operations more predictable. When your packaging follows a consistent structure, it becomes easier to manage weight thresholds, reduce wasted space, and stay within dimensional weight guidelines set by carriers.

This directly impacts your shipping costs. A product packed in the right-sized box avoids unnecessary fees, reduces filler materials, and minimizes damage during transit. Over time, it improves your profit margins without requiring drastic process changes.

It also streamlines workflows on the warehouse floor. With fewer box types to manage, packing decisions are faster and more accurate. Your team spends less time choosing packaging and more time shipping orders efficiently.

For operations teams managing hundreds or thousands of daily shipments, standardization introduces repeatability. It helps you keep your packaging warehouse organized, your staff better trained, and your fulfillment performance more consistent.

Right-Sizing vs Over-Engineering: A Practical Guide to Box Design Decisions

Choosing the correct packaging box size is all about aligning protection, shipping cost, and operational ease. But too often, teams either over-design packaging or apply a one-size-fits-all mentality that leads to inefficiencies.

Here is how to design smarter:

- Start with dimensional data: Begin with the actual measurements of your top-moving SKUs. Map them against available box sizes to identify coverage gaps and overlaps. This ensures you are building a size matrix based on real shipping volume, not theoretical options.

- Optimize the balance between void and fill: Use less than 20% void fill on average per box. If you are using more, you are likely oversizing. If you are using none, check that fragile items are still adequately cushioned. Right-sizing aims to keep fill costs low without compromising damage rates.

- Avoid structural overkill: Double-wall boxes are not always necessary. Use edge crush test (ECT) data and historical claim rates to determine when lighter material grades can do the job. Many non-fragile items ship safely in 32 ECT corrugated with proper inserts.

- Segment your box design strategy by product class: Assign standard packaging types to common product categories (electronics, apparel, hard goods). This lets you streamline storage, training, and box ordering while still accommodating key variations.

The following table helps you better understand the difference:

| Factor | Right-Sizing | Over-Engineering |

| Box Fit | Closely matches product dimensions | Excess space or oversized box usage |

| Void Fill Usage | Minimal (≤20%) | High (wasted fill or unnecessary cushioning) |

| Material Grade | Based on ECT needs and product fragility | Often defaulted to thicker grades (e.g., double-wall) |

| Storage Footprint | Fewer SKUs, optimized for volume | More SKUs, fragmented warehouse packaging storage |

| Packaging Speed | Faster decision-making and packing | Slower due to size confusion or manual adjustments |

| Cost Efficiency | Lower shipping and material costs | Higher dimensional weight and material spend |

| Damage Rate | Low, if protection is calculated properly | May be lower, but with diminishing returns on protection |

| Inventory Planning | Predictable box reordering | Complex stock forecasting, potential deadstock |

| Sustainability Impact | Lower material waste, less shipping emissions | More waste, increased carbon footprint |

| Ideal Use Case | Most general-purpose shipping operations | Niche items, fragile goods, high-value equipment |

What Operations Teams Can Implement & Manage

Standardization is not just a packaging decision, it is an operational strategy. And operations teams are in the best position to implement systems that bring-in efficiency without disrupting day-to-day throughput.

Here is what can be realistically managed at the ground level:

Packaging SKU Rationalization

Start with a usage analysis. Track which box sizes are used most frequently and which sit idle. Eliminate or consolidate low-volume SKUs. A tighter SKU set makes storage cleaner, training faster, and replenishment more predictable.

Integration with WMS

Many warehouse management systems (WMS) allow you to link products to preferred box sizes. When an order is picked, the system recommends the optimal box. No guesswork, no waste. Use this to reduce decision-making time and packing errors.

Custom Die-Cut Box Programs

For high-volume or oddly shaped SKUs, explore custom die-cut boxes. These reduce fill material, improve unboxing, and protect better in transit. Operations teams can work with procurement to implement these options selectively, only where they create real value.

Real-Time Feedback Loops

Create a channel for packers to flag recurring issues, like products that don’t fit standard boxes or require excessive fill. These insights drive smarter purchasing decisions and ongoing optimization.

Onboarding & SOP Alignment

With standardized box sizes in place, update your training materials and standard operating procedures. When everyone follows the same process, you reduce variance and make performance measurable.

All in all, box size standardization is more than a one-time decision. It is rather a habit that must be maintained through data, discipline, and team feedback. And when operations leads the charge, the results show up in both cost savings and process clarity.

Your Warehouse Packaging Transformation Starts Here

Box standardization simplifies how your warehouse runs. From storage planning to shipping cost control. When you define a clear set of box sizes around your most common order profiles, everything from procurement to training becomes easier.

Start by reviewing your top 20 SKUs and mapping them to 5–7 efficient box sizes. Validate against dimensional weight thresholds and existing racking layouts. Then work with your packaging supplier to lock in specs and streamline inventory.

This small operational shift reduces decision fatigue, lowers per-order packaging costs, and frees up floor space. It also makes it easier to introduce automation and maintain quality as you scale.

And if you are exploring custom die-cut boxes for warehouses, or looking to improve warehouse packaging storage,UCanPack can support with durable, cost-efficient solutions tailored to your operation.

Smarter packaging starts with smarter structure.