What Makes a Box ‘Eco-Friendly’- and How to Avoid Greenwashing in Packaging Supplies

Introduction

Everyone’s slapping green labels on their packaging these days. “Eco-this,” “Earth-safe that.” But ask five suppliers what makes their packaging boxes sustainable, and you will surely get seven different answers, and a few blank stares.

That’s a problem.

For U.S. businesses, especially those scaling direct-to-consumer or managing bulk packaging orders, this kind of vagueness does not just lead to confusion. It leads to bad deals, failed audits, and packaging that ends up doing more harm than good.

And most of it still lands in landfills.

With pressure mounting from retailers, regulators, and customers, the stakes around “eco-friendly packaging” have never been higher. But what actually makes a box sustainable? Not in theory. Not in marketing speak. But in the supply chain, on the dock, and at the recycling center?

This detailed guide cuts through the noise. We are unpacking greenwashing tactics, verifying real certifications, breaking down life cycle data, and showing you where most businesses slip up, before their packaging even ships.

The Mislabeling Crisis in Packaging

A staggering 95% of so-called “green” products were found to make misleading environmental claims, according to a study by TerraChoice. That includes everything from vague promises to outright falsehoods, slapped on with a recyclable sticker and called a day.

Packaging is no exception. In fact, it is one of the worst offenders.

Walk into any supplier’s catalog and you will see terms like:

- Eco-safe

- Earth-friendly

- Eco friendly packaging

- 100% natural

- Sustainably sourced

Nice words. But what do they actually mean? Legally, almost nothing. Most of these phrases are usually not backed by verified data, certified sourcing, or any measurable benchmarks.

And this isn’t just a branding issue. It’s a supply chain risk. B2B buyers relying on false eco claims end up with packaging boxes that cannot pass retailer compliance, cannot be recycled curbside, or fail LCA audits. Worse, some buyers unknowingly push packaging that increases emissions because it is greenwashed, not green.

Material Certification Isn’t Optional Anymore

Saying your box is “sustainable” without certification is like selling food without an ingredient list. Sure, it looks fine, but no one really knows what they are getting.

Today’s buyers, especially B2B procurement teams, don’t just ask what your packaging is made of. They want the actual proof. That means verified supply chains, trackable sources, and third-party validation.

Here is where real certifications come in:

- FSC (Forest Stewardship Council): Ensures that paper products come from responsibly managed forests.

- SFI (Sustainable Forestry Initiative): Combines forest certification with environmental conservation.

Cradle to Cradle Certified: Tracks health, recyclability, water stewardship, and renewable energy use across product life.

Now, here is the catch.

Many packaging box manufacturers claim their materials are certified… but that doesn’t mean their actual packaging is. Unless the end product is certified (and documented), that FSC logo means nothing. You are left with a vague promise and a big question mark.

Today, more U.S. packaging companies are losing bulk contracts because their packaging doesn’t meet sustainability compliance thresholds. Retailers and distributors are tightening their onboarding rules and they are not wasting time with unverifiable claims.

So if you are sourcing high-volume eco friendly packaging boxes, especially for regulated industries or retail-bound goods, choose suppliers who work directly with certified mills and transparent processing facilities.

Take pre-stretch films, for example. Businesses exploringbiodegradable wrap options are already moving toward lighter shipping loads and smarter disposability, while aligning with broader sustainability benchmarks.

When materials speak for themselves, you don’t have to.

Greenwashing Patterns Most U.S. Suppliers Still Follow

A certified-looking logo. A recycled badge slapped on a product sheet. And suddenly, a packaging supplier looks “green.” But when you dig into the process, many of these claims fall apart.

Here is how greenwashing is still baked into standard packaging sales in the U.S. And why B2B buyers need to spot it before it costs them:

1. Ambiguous Percentages with No Audit Trail:

You will often see “made with up to 50% recycled content” on box listings. But what batch? What grade? Post-consumer or post-industrial? If there is no chain-of-custody documentation (like from FSC or SFI), it’s just marketing filler. There is no standard enforcement unless you demand it.

2. Fake or Expired Environmental Seals

Yes, this still happens. Some suppliers still display expired certifications or outdated compliance logos (especially Cradle to Cradle, ISO 14001, and Green Seal). Others copy logos without proper usage rights. Unless the cert is traceable by lot or facility, it doesn’t count.

3. Hiding Behind “Recyclable” Without Location Context

A box can be labeled “recyclable” but still be unrecyclable in 80% of U.S. curbside systems. If your packaging uses coatings, foils, UV varnish, or laminated inserts, local MRFs (Material Recovery Facilities) might treat it as landfill. Ask for compatibility data, not just a word on a spec sheet.

4. Bulk Claims Without Breakdown

When a vendor claims, “All our packaging is eco-friendly,” dig deeper. Does that include your custom dieline? The specific board grade? The tape and inner components? Blanket claims are the #1 greenwashing red flag in wholesale sustainable packaging sales.

Life Cycle Analysis: The Only Benchmark That Matters

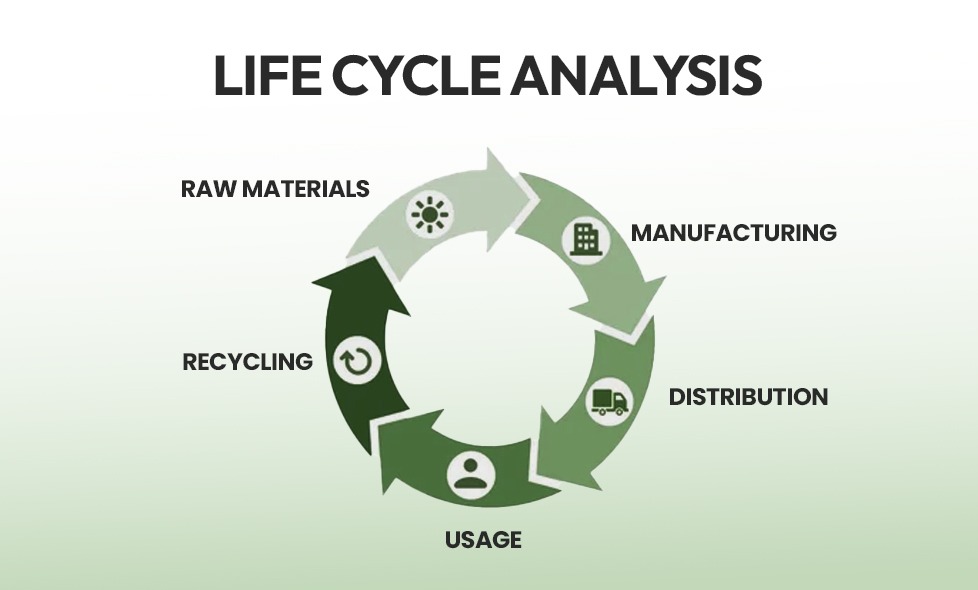

“Eco-friendly” starts long before a box hits the shelf and doesn’t end when it is tossed in the bin. This is why serious buyers and sustainability officers are relying on Life Cycle Analysis (LCA) to validate packaging claims.

Unlike surface-level certifications or supplier promises, LCA digs into the full environmental impact of your packaging product, starting from raw material extraction to end-of-life disposal.

Why a Box’s Entire Lifecycle Beats Any Single “Green” Label

A recycled logo doesn’t mean low impact. A kraft board doesn’t mean zero emissions. What matters is how that box performs across each stage:

- Raw Materials: Virgin fiber vs recycled pulp, plus the energy used to process each

- Manufacturing: Type of equipment, local energy sources (coal-fired vs renewable), water usage, waste handling

- Transportation: Whether the packaging travels 60 miles or 6,000 before it gets to your dock

- Usage Phase: How it behaves in real fulfillment; dimensional weight impact, stacking strength, and damage rates

- End-of-Life: Curbside recyclability, landfill rates, microplastic shedding, or compost facility acceptance

If your supplier cannot produce even a basic LCA snapshot or third-party impact report, it is completely guesswork. And no, quoting “biodegradable” stats from raw material vendors doesn’t count. You need product-level data, not category-level marketing.

Domestic vs Imported “Sustainable Packaging”

Let’s say you are comparing a U.S.-made corrugated mailer to an imported “green” box made from 70% recycled fiber. This table breaks down the operational and environmental differences between typical imported packaging and verified U.S.-made alternatives:

| Criteria | Imported Boxes | U.S.-Made (LCA Verified) |

| Freight Emissions | 5,000+ miles via ocean freight → ~4 metric tons CO₂ per 40’ container | Local sourcing (500–1,000 miles) = significantly lower transport emissions |

| Material Transparency | Often uses mixed-source pulp without traceable FSC chain-of-custody | Verified FSC/SFI fiber blend with full documentation |

| Structural Integrity | Inconsistent GSM, thin liners, higher failure in crush/moisture testing | ECT-tested liners, consistent GSM, built to spec for compression and stacking loads |

| Print & Adhesive Safety | Solvent-based inks, high-VOC glues in many offshore runs | Water-based inks, low-VOC adhesives, safe for most retail and food compliance needs |

| Recyclability | Often contaminated with waxes, foils, or multi-material laminates | Curbside-compatible designs, recyclable tapes and mono-material structure |

| Operational Impact | More returns, higher damage rates, slower repacking due to weak box integrity | Faster fulfillment, lower returns, better fit with automation and warehouse handling |

Key LCA Metrics Worth Tracking

Make these part of your packaging procurement check:

- Global Warming Potential (GWP): Total CO₂ emissions per unit

- Cumulative Energy Demand (CED): Energy input from source to ship

- Water Footprint: Total liters consumed and treated

- Post-Consumer Content %: Not just recycled, what kind of recycled

- End-of-Life Scenario: Landfilled, recycled, incinerated (by region)

Final Checklist: How to Know Your Packaging Is Actually Eco-Friendly

Now that you have gone through the technical side of things, it's time to address the real question: what makes a packaging box eco friendly?

Here is a practical checklist you can run through before you place your next packaging order:

- Is the material source certified and traceable?

Check for valid FSC or SFI documentation tied to your specific batch.

- Does your supplier provide a product-level LCA report?

Ask for lifecycle data specific to the packaging SKU you’re ordering.

- What’s the actual recycled content and of what type?

Post-consumer > post-industrial. Ask for a breakdown and how it impacts structural performance.

- Can every component be recycled curbside in your delivery zones?

This includes tapes, coatings, and inserts. “Recyclable” doesn’t mean anything if your local MRF can’t handle it.

- Is the packaging designed for efficient logistics?

Flat-packed, dimensionally optimized boxes cut both emissions and freight costs. Oversized or overbuilt boxes burn fuel and waste space.

- Does it meet your retailers’ compliance standards?

If you ship to Amazon, Walmart, or Target, your box needs to be automation- and testing-friendly.

- Does it include any non-compostable or synthetic fillers?

Foam peanuts, mixed plastic windows, or metalized prints disqualify the entire unit from compost streams.

If your current supplier avoids these questions or cannot provide clear answers, that should raise a red flag.

Eco-friendly packaging is all about traceability, measurable impact, and real-world performance at every stage of the supply chain.

So, start asking better questions. And only pay for packaging that’s built to meet the standards your business actually needs. At UCanPack, we build packaging that answers every one of these questions up front.

After all, every box you ship is part of your brand’s footprint!