Made in USA vs Imported Boxes: What B2B Buyers Should Know Before Placing a Bulk Order

Introduction

You have two quotes on your desk. One from a domestic supplier. One from overseas. The numbers look different, but both claim to deliver high-quality packaging.

For example, across the country, demand for corrugated packaging is climbing. According to the Freedonia Group, the U.S. corrugated box market is projected to reach over $52 billion by 2027. This growth shows the steady rise in e-commerce, logistics expansion, and domestic manufacturing investments.

When a supply chain depends on speed, accuracy, and protection, packaging becomes more than just a container. It becomes part of the whole product experience. And for many U.S. businesses, working with American manufacturers brings consistency, faster lead times, and easier communication.

Choosing between imported and U.S.-made packaging boxes go beyond price per unit. The real difference shows up in operations, timelines, and customer satisfaction. That is where this comparison starts.

Let’s break it down properly. Box by box.

The Surface-Level Cost Trap Most B2B Buyers Walk Into

At a glance, you would feel that imported boxes often win the price war. The base cost per unit is usually lower. The savings feel immediate. For bulk packaging boxes, that initial number can look like a done deal.

But those numbers rarely tell the whole story.

Let’s break it down.

| Factor | Imported Boxes | Made in USA Boxes |

| Lead Times | Often 45–90 days | Typically 5–15 days |

| Freight Charges | High, variable, container-based | Lower, zone-based, predictable |

| Duties & Tariffs | Subject to sudden hikes | No import taxes |

| Minimum Order Quantities (MOQs) | Higher due to overseas batching | More flexible options |

| Currency Fluctuation | Exposed to foreign exchange risk | Priced in USD |

| Damage/Loss Risk | Higher during long-distance transit | Higher during long-distance transit |

| Communication Delays | Time zones, language gapsLocal teams, same-day responses | Local teams, same-day responses |

The upfront savings from offshore packaging fade quickly when shipping gets delayed, or customs adds another layer of paperwork. Even a single order stuck at port can disrupt your production schedules or lead to missed delivery promises.

U.S.-made packaging boxes cost more on paper but often result in fewer operational headaches. For B2B buyers placing large orders, these ripple effects create real financial consequences.

A box that costs less but arrives late isn't saving you money.

Quality Standards & Consistency: The Real Differentiator

When packaging is your first impression, inconsistency is not just risky, it’s expensive. Especially at scale.

Imported boxes often come with variability. Different production batches. Inconsistent board grades. Fluctuating GSM and edge crush strength. Some shipments meet spec. Others don’t. And when you are bulk ordering packaging boxes, even a 3% failure rate can mean thousands of unusable units.

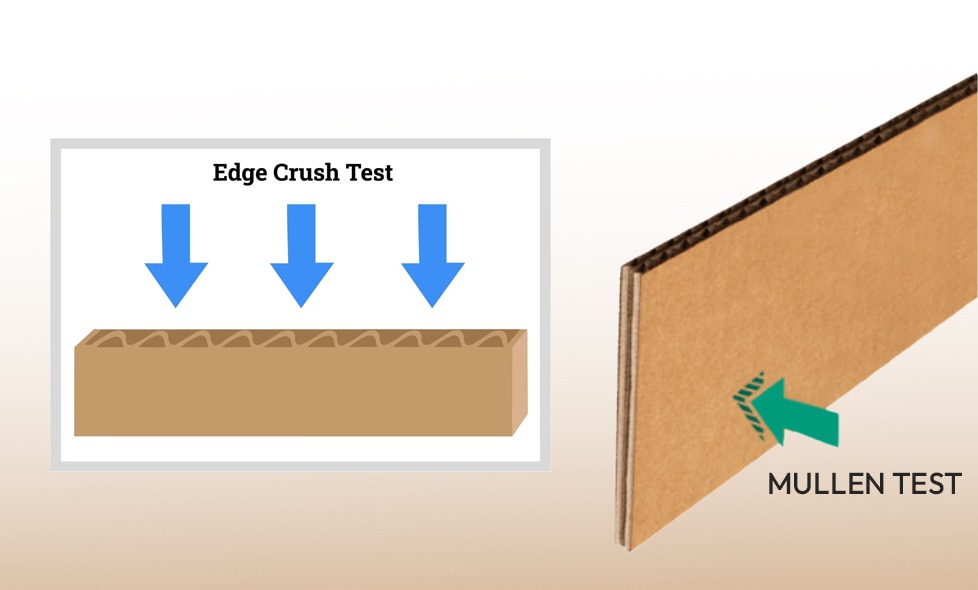

On the other hand, U.S.-made packaging boxes operate under tighter compliance. Most domestic manufacturers adhere to standard tests like the Mullen Burst Test or the ECT (Edge Crush Test) to verify structural strength. And they are not just checking at the start of the run; they are inspecting during, after, and every time they scale.

There is also accountability. If something goes wrong, you are one phone call away from a resolution, not a 14-hour timezone lag and weeks of back-and-forth.

Custom packaging boxes made in the USA tend to hold tighter tolerances in printing, die-cut precision, and moisture control. This means fewer surprises, lower returns, and a more consistent customer experience on your end.

And when your brand rides on the box it ships in, that matters a lot more than most finance sheets account for.

Environmental and Sustainability Considerations

There is surely no shortage of companies claiming to “go green.” But when you are shipping thousands of units a week, the conversation shifts from slogans to real numbers.

Packaging is often one of the most overlooked contributors to carbon footprint in a supply chain. And yet, it sits at the center of sourcing, transport, and end-of-life waste.

Imported boxes don’t just carry duties and freight charges. They carry months-long emissions trails. A single 40-foot container shipped from East Asia to the U.S. can add 4 metric tons of CO2 to your books; before the boxes even hit your loading dock.

With U.S.-made packaging boxes, that number drops sharply. Ground freight across zones emits far less, and you are not building weeks of idle time into your environmental impact.

Then there’s the question of materials. Domestic manufacturers are under tighter regulation. Most use post-consumer recycled content, FSC-certified liners, and water-based inks as standard. You get more transparency, and fewer question marks.

Even smaller packaging products like kraft paper bags, often used for lightweight fulfillment or secondary wrapping, are being re-evaluated. Choosing a U.S.-made kraft paper bag means fewer virgin fibers, reduced microplastic reliance, and full recyclability. Something that's becoming a procurement requirement for large retail buyers.

So, if you're sourcing at volume, local packaging gives you control, clarity, and a cleaner supply chain.

Decision-Making Framework for B2B Buyers

Choosing between imported and U.S.-made packaging is rarely just a budget line item. For most B2B buyers, it’s a decision with supply chain, operational, and brand-level implications.

Here is a practical lens to evaluate your next bulk packaging order:

- Total Cost of Ownership (TCO). Go beyond the unit price. Factor in duties, freight surcharges, buffer stock, spoilage, repacking, and rush shipping for delays. Cost per box means little if you are absorbing losses downstream.

- Lead Time Tolerance. Map out your production and fulfillment windows. If delays create bottlenecks or missed SLAs, shorter lead times from domestic suppliers add more value than low-cost offshore units ever could.

- Material Requirements and Specs. Imported boxes often use inconsistent board grades across batches. If you're shipping fragile items, or printing detailed branding, domestic options with verified GSM, ECT, and print tolerances are safer bets.

- Supply Chain Flexibility. Need to split shipments? Change artwork mid-run? Pull a partial batch early? Domestic vendors can usually accommodate changes without weeks of negotiation. That agility pays off during product launches or demand spikes.

- Compliance and Documentation. If you're answering to procurement audits, industry certifications, or partner ESG benchmarks, traceability matters. Local manufacturers are more likely to provide FSC, SFI, or recycled content certifications without pushback.

- Customer and Brand Impact. Packaging is the first physical touchpoint. Damaged corners, faded ink, or box warping tell your customers a story, and it’s not a flattering one. U.S-made custom packaging boxes tend to hold better consistency in structure and appearance across the entire run.

- Vendor Accountability. Time zones and language gaps create barriers. Domestic partners usually respond same-day, and escalations are easier when there is a mutual legal framework, local accountability, and zero translation lag.

The fewer variables you leave to chance, the fewer surprises your operations team will have to clean up. Packaging doesn’t need to be unpredictable. It needs to work. Every time. Across thousands of units. With zero babysitting. When your supply chain is under pressure, predictability becomes its own form of ROI. And the right packaging partner helps you lock that in early, before the first box even rolls off the line.

At the End of the Day: Made in the USA Matters

By now, you might have seen how packaging choices affect more than just price tags. Bulk packaging boxes from overseas might look cheaper at first, but the real story is about lead times, quality, and the smooth flow of your supply chain. U.S.-made packaging boxes bring reliability, faster responses, and consistent quality that keep your operations steady and your customers satisfied.

Every business has its own priorities. Be it cutting costs, meeting tight deadlines, or hitting sustainability goals. Knowing what matters most helps you make smarter decisions when buying packaging boxes in bulk.

And if you want packaging solutions that work as hard as you do, take a closer look at UCanPack’s range of custom packaging boxes USA. From small packaging boxes bulk orders to wholesale packaging boxes, we are here to support your business with products built for performance and peace of mind.