The Real Cost of Custom Packaging: What Small Businesses Overlook

Introduction

There is a perception that packaging doesn’t have an impact on a brand’s image. Often, businesses just use those boring brown boxes to pack their products. However, with the rise of social media, customers have started noticing the little things. If they like a product, they want to post about the brand, they want to talk about the experience. A flimsy box or lazy design? That doesn’t make it to their story. But a thoughtfully packed one? That’s free marketing you didn’t even have to ask for.

Around 72% of consumers say the design of a package can sway their buying decision. This is a stat that reveals just how much the box matters before anyone even opens it. Primarily for small and mid-sized businesses, this creates an opportunity to use packaging as a strategic tool that brings in sales and builds lasting customer loyalty.

Understanding how packaging influences consumer behavior gives businesses the clarity to make smarter investment choices. But to truly maximize its potential, it is essential to break down the many elements that contribute to custom packaging costs. Each factor plays a role in both brand perception and bottom-line efficiency.

Breaking Down the True Costs Behind Custom Packaging

Custom packaging involves more than just choosing a box design. Several factors contribute to the overall expense, and understanding each one is key to making smart decisions.

- Setup Fees. It often comes as a first surprise. These cover the initial costs of creating molds, printing plates, or cutting dies tailored specifically to your design. Setup fees are typically one-time charges but can be significant, especially for smaller runs.

- Minimum Order Quantities (MOQs). It is another important consideration. Suppliers often require a minimum number of units per order to justify production costs. These minimums affect inventory planning and cash flow, particularly for businesses with limited storage space.

- Material Selection. Packaging materials vary widely in price depending on durability, sustainability, and aesthetic qualities. High-end materials enhance brand perception but can influence cost-per-unit substantially.

- Production Waste. These are the scraps and rejects that end up during manufacturing. Efficient design and close coordination with suppliers help minimize this, but it remains a cost many underestimate.

- Storage and Logistics. Lastly, this also adds layers of expense. Packaging takes up space, and managing inventory means considering warehousing fees and transportation costs.

To better understand where packaging budgets often go beyond expectations, let us break down each overlooked factor one by one.

Setup Fees and Their Impact on Budget Planning

Setup fees are often the first substantial cost in custom packaging. These charges cover the creation of printing plates, molds, and cutting dies unique to your design. They require skilled labor and specialized equipment, which explains why they come as a fixed upfront expense regardless of order size.

From a technical standpoint, setup fees vary depending on:

- Printing Process: Flexographic printing generally requires more elaborate plate making than digital printing, influencing costs.

- Die-Cut Complexity: Intricate shapes or multiple cut lines increase die creation time and expense.

Color Usage: Each additional color in printing demands a separate plate, which raises setup fees.

Smaller orders feel the impact of setup fees more sharply because these costs are amortized over fewer units. Businesses ordering fewer units should carefully evaluate how setup fees affect per-unit pricing.

Getting into the technical side of things can help reduce the setup fees. For example, standard dielines and modular designs allow reusing plates, cutting down costs. Early engagement in design discussions also avoids costly redesigns after setup begins.

Planning for setup fees as an initial step helps businesses accurately forecast packaging budgets and avoids surprises during production

Minimum Order Quantities and Why They Matter

Minimum Order Quantities, or MOQs, are a big deal in custom packaging. They are the smallest number of units a supplier will produce in one run. This rule exists because running machines, ordering materials, and setting up production all come with a price, no matter how many boxes you order.

For small businesses, minimum order quantities packaging requirements can feel like a trap. You might have to buy more packaging than you need, tying up cash and filling up storage space. But understanding why MOQs exist helps you plan smarter and maybe even negotiate better.

Material Selection and Its Impact on Costs

Not all packaging materials feel the same. Some materials are tough, others flimsy. And yep, that difference shows up in the price.

You can go with plain cardboard or splash out on something fancy and eco-friendly. The fancier the material, the more it usually costs. But good packaging materials can make your product look like a million bucks, while cheap stuff might send the wrong message.

Plus, heavier or bulkier materials can jack up your shipping bills or require more storage space. The trick? Finding a balance that fits your brand without blowing your budget.

Not sure what materials to even consider? In this blog, you can check out a breakdown of some of the most common packaging supplies and what they are typically used for.

Hidden Waste Costs You Don’t See on the Invoice

Every custom box tells a story. But behind the scenes, there is usually a trail of waste. Not the kind you can toss in a bin, but the kind that quietly chips away at your margins.

We are talking about design misprints, production overruns, and excess materials ordered "just in case." These don’t always show up in the final quote, but they hit your bottom line all the same.

Here is a simplified view of where packaging waste usually sneaks in:

| Source of Waste | What It Looks Like | Cost Impact |

| Over-ordering materials | Ordering extra units to meet MOQs or cover ‘what if’ cases | Ties up cash and storage space |

| Design errors | Incorrect dielines, misalignment, or too much ink coverage | Leads to reprints or redesigns |

| Poor fit | Box too big/small for product, causing damage or excess fill | More returns, more padding used |

| Inefficient shapes | Non-stackable or awkwardly shaped packaging | Higher shipping/storage costs |

The fix? Get intentional. Use dielines that minimize material waste. Talk to your supplier early. Avoid guesswork by testing a prototype before full runs. It is small changes like these that keep you from paying for trash (literally).

Storage Costs Businesses Often Overlook

Packaging costs don’t stop once the order is placed. Storing packaging materials adds expenses that many businesses underestimate.

For example, ordering three months’ worth of custom packaging boxes means having a large inventory sitting around. If sales slow down or shipping is delayed, those boxes stay unused longer, tying up capital.Storage expenses

include more than just warehouse rent. Extra labor to manage and organize inventory, the risk of damage from long-term storage, and the chance that packaging materials become outdated all add to costs.

Even businesses with sufficient storage space face challenges like increased handling time and complicated warehouse operations.

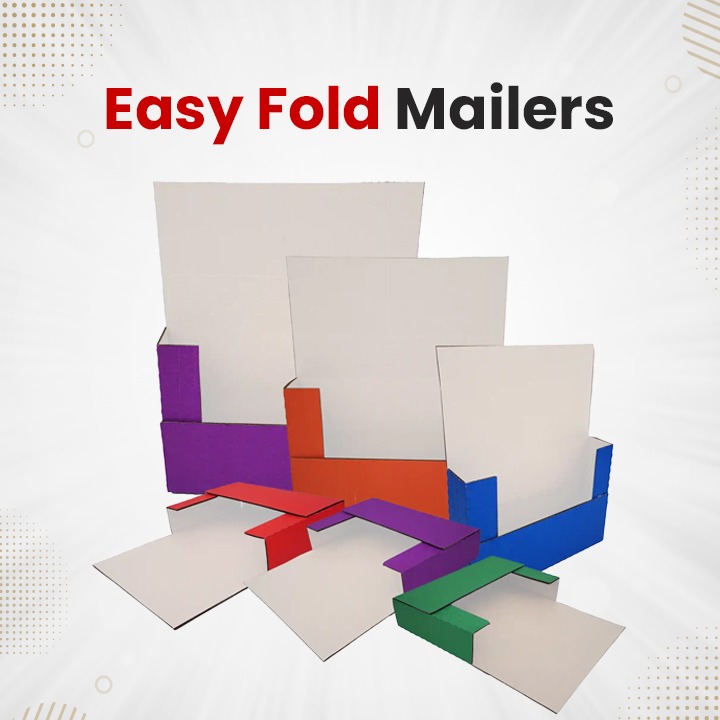

Choosing packaging solutions like Easy Fold Mailers can also help. These mailers save space by folding flat and can be quickly assembled when needed, reducing storage demands and improving efficiency.

Balancing packaging orders to meet demand without overstocking helps control costs and keeps cash flow steady. Recognizing these storage costs leads to smarter budgeting and prevents unexpected expenses.

Final Thoughts on Managing Packaging Costs

Custom packaging shapes how your brand is seen and how your business runs. Costs like setup fees, minimum orders, material choices, waste, and storage all quietly add up. Understanding these hidden expenses helps you plan better and avoid surprises.

Smart businesses work with suppliers who get their needs and find packaging solutions that fit both brand and budget. Ordering thoughtfully and choosing efficient materials keeps costs in check while making a strong impression on customers.

When you are ready to take control of your packaging, Ucanpack offers a range of options designed for businesses looking to balance quality, cost, and convenience. After all, thoughtful packaging isn’t just about luxury; it’s part of building a brand customers trust and remember.