Measuring Boxes 101: Inside vs Outside Dimensions & Getting the Perfect Fit

Fit Begins with the Function, Not the Ruler

When you are packing a product, especially one that’s fragile, oddly shaped, or meant to impress the end customer, the first thing you measure shouldn’t be the box. It should be the function. What exactly does that packaging box need to do once it’s filled, sealed, and on its journey?

Will it sit on a shelf for weeks? Will it go through multiple touchpoints in a warehouse? Will it carry branding that needs to stay pristine? Or is it simply expected to absorb some shocks and reach the destination in one piece?

These small packaging decisions don’t always feel like a big deal in the moment. But at scale, they add up fast. Amazon, for instance, reengineered its box sizing strategy to better match product dimensions across millions of shipments. With smarter fit, the company managed to reduce cardboard use by over 35% and eliminate more than 60,000 tons of waste in a single year. Multiply that by the scale of global logistics, and the impact is massive.

So, your tape measure can wait. Because getting the fit right begins with understanding the journey.

Decoding Dimensions: What You’re Actually Measuring

When manufacturers list box sizes, they are usually talking inside packaging dimensions which is the usable space inside the box once it is fully assembled. These measurements help determine whether your product will fit in the box.

But what about the outside dimensions? Those are what freight companies, warehouse shelving, and retail displays care about. A half-inch difference in exterior length can mean the difference between fitting five boxes per shelf or four. And that’s not a small cost difference over time.

Let’s break it down:

- Length is the longer side of the opening

- Width is the shorter side of the opening

- Height (sometimes called depth) is the distance from the opening to the bottom

Always double-check whether a supplier is quoting inside or outside dimensions. On bulk orders, that half-inch confusion can lead to pallets that do not stack right or products that do not fit at all.

The Wall Thickness Trap

Here’s where things get technical.

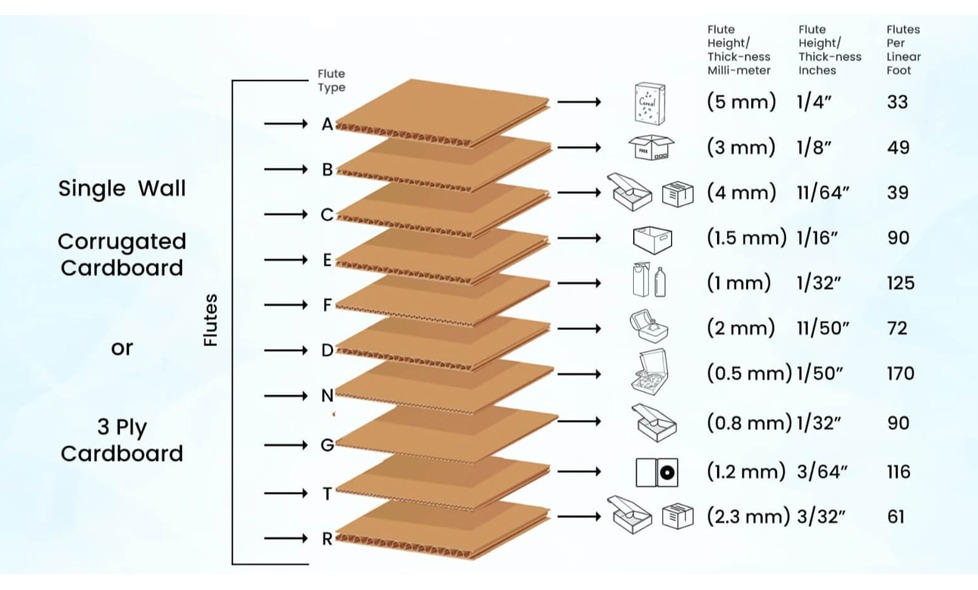

A single-wall corrugated box is typically around 1/8” thick (that’s B-Flute). Double-wall can go up to 1/4”, and triple-wall? Nearly 1/2”.

If your product fits perfectly into a box based on internal dimensions, do not assume it will squeeze into the next size down. Wall thickness eats space; quietly, invisibly, and often after you’ve placed the order.

When calculating outside dimensions for storage, shipping, or cube optimization, always account for the board thickness. A triple-wall 20x20x20 box might sit closer to 21 inches on every edge externally.

Need accurate specs? Check the product pages of most corrugated shipping boxes, they usually mention ECT ratings, flute type, and wall thickness to help you plan smarter.

Packaging Boxes Behave Differently When Loaded

An empty box is easy to measure. But a loaded box? That’s where performance varies.

Corrugated packaging behaves like a living system under pressure. Load-bearing stress can slightly bulge the sides or compress the top panel, especially if boxes are stacked.

This is why box construction matters so much. A 12x12x12 cube made with ECT-32 kraft might survive light retail use. But when you add 60 lbs of metal tools or start stacking pallets, the same cube with a double-wall or 44 ECT spec makes all the difference.

So before you finalize “fit,” ask yourself how that box will behave under load, during stacking, and when being handled. Use structural choices to guard against unexpected dimension creep.

Think in Volumes, Not Just Length x Width x Height

Here’s a smarter way to think: volume efficiency.

Imagine you are shipping 250 small boxes of cosmetics. You want to fit as many as possible into master cartons. Instead of guessing combinations, calculate the interior volume of the master carton and work backward.

Say your master carton has inside dimensions of 20x16x12 inches. That gives you 3,840 cubic inches. Now measure the outside of the cosmetic boxes and play a little 3D Tetris. How many can you fit with minimal air gaps?

Not only does this approach improve packaging density, it reduces filler waste, cuts freight cost, and boosts sustainability. It also makes repeatable, scalable packaging workflows much easier.

Measuring for Inserts, Fillers, or Foam? Think Backwards

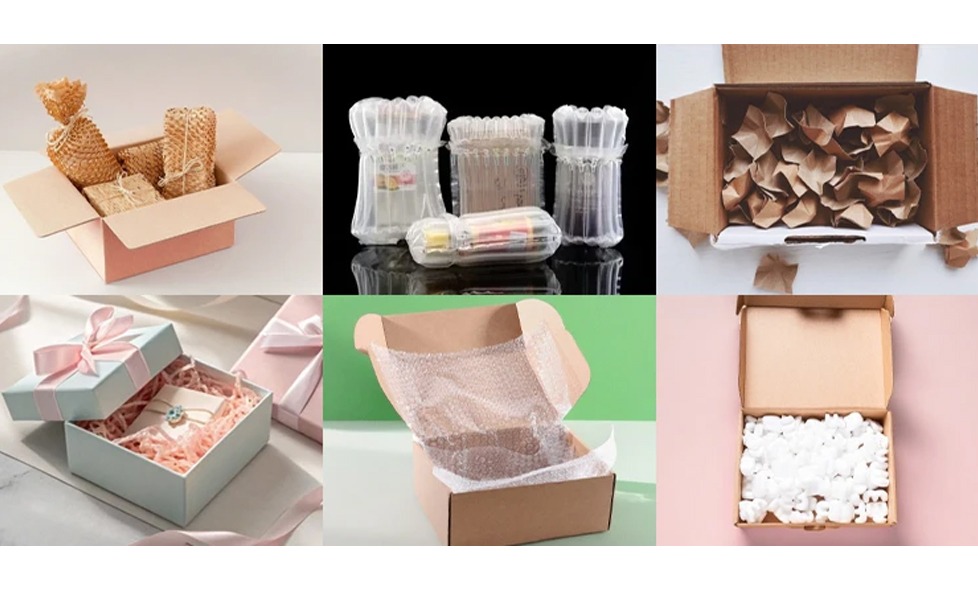

When measuring for protective packaging, the outer box comes after you have chosen your inner support system.

If your product needs a foam insert, retention frame, or divider, you will want to first prototype those dimensions. Once the internal structure is locked, measure that total shape to determine the required inner box space.

And don’t forget that certain inserts need compression. For example, a water-activated tape dispenser with retention film might need a tight frame to hold it in place. That tension changes the required space slightly.

Most users who go for custom printed easy fold mailers or use die-cut inserts follow this inverted logic. They build from the inside out to avoid rework.

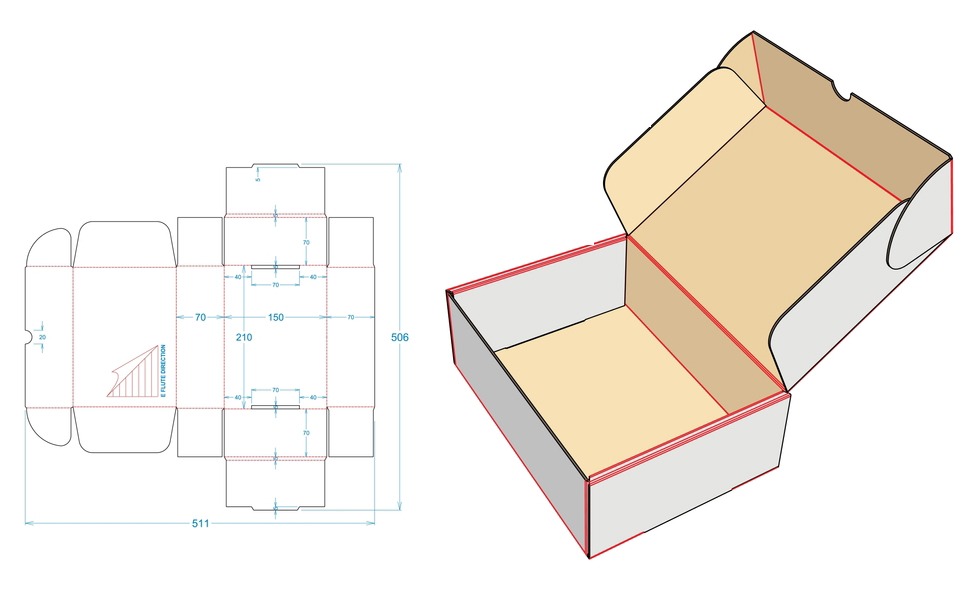

Why Tape, Flaps, and Closures Change Everything

A box won’t seal itself. Either you are using a glue gun, hot melt tape, or water-activated tape, your closure method affects how much space you need on every side.

For instance:

- Water-activated tape creates a strong seal but adds about 1/8” bulk to the overlap

- Reverse tuck flaps may interfere with product fit unless the object is slightly shorter than the box

- Overlap flaps or telescoping lids require height buffers to close smoothly

If you ignore these elements, you end up forcing closure or compressing the product. Both result in structural weakening or visual damage during delivery.

A good rule of thumb: leave 3/16”–1/4” buffer on all sides unless your inner item has built-in padding or protection. Precision fit might look great in CAD but reality likes margin.

Think Like a Brand That Measures with Purpose

Anyone can pick a box that “kind of” fits. But brands that win at scale? They treat every inch like it matters. Because it does.

A little too tight, and your product gets squished or scratched. A little too loose, and you’re wasting filler, freight cost, and storage. These small mismatches pile up across warehouses, shelves, and customer expectations.

Want to tighten up your packaging game? Start with questions like:

- How is the box handled, by humans or machines?

- Does the closure need buffer space for tape, flaps, or reinforcements?

- Will internal packaging add pressure from within?

- Can different products within the same size class share packaging specs?

- Is the shape helping or hurting storage optimization?

And if your workflow involves automation, tight turnarounds, or high-volume SKUs, there is even more at stake. A 1/4” miscalculation might not ruin a single delivery, but repeat it across thousands? That’s a silent leak in your system.

Even when using standard box sizes, you can still get strategic. Multi-depth cartons offer built-in flexibility. Cube boxes reduce movement inside. Flat boxes ship and store better. It’s all about what helps your operation move smoother.

So don’t treat dimensions like background details. See them for what they really are. Little levers that control how fast, how safe, and how professional your packaging feels.

Extra Tip: Watch the Margins

Even when packaging box dimensions look perfect on paper, margins are where fit gets tricky. A box might promise 12 inches inside, but are all 12 usable?

Here is why margins matter more than most think:

- Corner crush zones can steal a quarter inch.

- Fold lines or internal seams can slightly narrow usable width.

- Boxes made on high-speed lines may carry tiny variances batch to batch.

The smarter way? Always subtract a small buffer (around 1/8” to 3/16”) from your internal specs when checking fit. This accounts for manufacturing tolerances, real-world material behavior, and closure compression.

It’s the difference between a snug fit and a forced fit.

Concluding the Measurement Maze with Clarity

Box measurement goes beyond raw numbers. It’s about reading those numbers in context and understanding how each one plays a role in the real world.

The best-fit box considers not only the product but how it moves, how it’s protected, how it’s presented, and how it behaves in the real world. From wall thickness to filler space, from closure overlaps to label placement, each measurement tells part of the story.

UCanPack understands this at a cellular level. If you’re ordering basic kraft shipping boxes, configuring protective bulk cargo cartons, or engineering a full DTC unboxing experience, our approach starts with understanding your dimensions in use, not just on paper.

Need help finding your perfect fit? Start measuring smarter, packing stronger, and reducing rework. Because when the box works, everything downstream flows better.