One Size Doesn’t Fit All: Packaging Solutions for Diverse Product Lines

“Which Box Do We Use for This One?”

Somewhere on a warehouse floor, someone might be holding a box in one hand and a product in the other. The product does not quite fit. It shifts too much. The corners push out. Void fill is added, tape gets doubled, and shipping time increases. Multiply that scene by 50 SKUs and hundreds of orders per day. That is the real cost of not having the right packaging system in place.

As your product line grows, packaging complexity follows. What once worked for three SKUs stops working for thirty. That is when packaging stops being a creative conversation and becomes an operational one.

Recent market data from S&P Global confirms that the packaging sector is now prioritizing operational leverage over volume growth, as SKU diversity and fulfillment costs weigh more heavily than ever.

So, you don’t just need boxes. You need a system. One that scales with your product variety, protects your goods, makes your fulfillment team faster, and still makes your brand look good on arrival.

Let us explore what that actually takes.

Why Box Variety Is a Supply Chain Problem, Not a Design Problem

Packaging is often misunderstood as a branding decision. But for growing businesses, it is a supply chain decision. One that affects speed, cost, and customer experience. Here is why:

- Order Consolidation: When packaging does not match product dimensions, you lose the ability to consolidate SKUs into single shipments efficiently.

- Picking & Packing Efficiency: If staff must guess which packaging box fits each product, fulfillment slows down. That delay adds labor cost and risk of error.

- Warehouse Space: A stack of oversized boxes wastes valuable racking. Undersized ones increase returns.

- Return Rate & Damage: Using packaging that does not support product weight or form leads to in-transit damage, especially when dealing with fragile, irregular, or stacked items.

- Customer Perception: An over-packed box doesn’t just cost more. It feels careless.

The misalignment between box design and product shape is clearly annoying but it also creates friction across your entire logistics chain.

“But Can’t We Just Pick One Size and Use Void Fill?”

Many businesses start here. It is simple. Just stock one or two box sizes and fill the gaps with air pillows or kraft paper.

It works for a while. Until it does not.

Using excess void fill doesn’t just look bad. It creates:

- Higher dimensional weight charges: You are literally paying to ship air, not the product.

- More packaging material waste: Which increases your sustainability footprint.

- Longer packing time: More steps = more labor.

- Weaker protection: No void fill can fully compensate for an ill-fitting box.

- Inconsistent unboxing: Which matters a lot in DTC or gifting scenarios.

A single-size strategy is easy to manage, but it rarely holds up when you introduce products with different shapes, fragility levels, or shipping destinations. At that point, it is no longer a question of aesthetics; it is one of function and efficiency.

Let’s Talk Fit Tolerance, SKU Mapping, and Structural Logic

The best packaging systems aren’t built by adding more box styles randomly. They are engineered.

Here is how most brands make it work:

- SKU Dimension Clustering: Start by grouping your products by dimension and fragility and not by product category. A mug and a candle might go in the same box if their dimensions are similar.

- Structural Logic: Choose styles based on function. Die-cut mailers boxes for lighter, presentable items. Double-wall RSCs for bulk or weight-heavy products.

- Modular Inserts: Foam cradles, kraft inserts, and flexible corrugated trays help standardize outer packaging while customizing the internal fit.

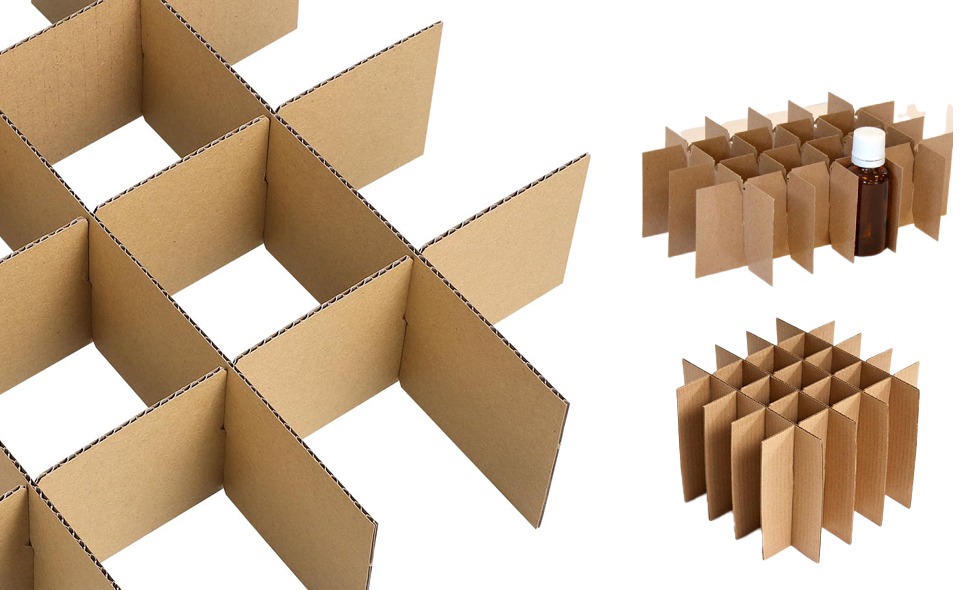

- Adaptive Dividers: Especially useful in skincare, candle, food, or apparel kits where multiple items of varying sizes ship together.

- Variable Wall Strength: Use 32 ECT single wall for light retail, but 275# or 51 ECT double-wall for heavier SKUs.

The logic is simple: match product needs with box structure, and you reduce waste, returns, and more importantly, packing time.

This is where packaging stops being visual and becomes operational.

How Some Brands Pull It Off with Only 3 or 4 Box SKUs

It is not about having 50 different boxes. It is about having the right 3 or 4.

Smart packaging is like a clean toolkit. Many DTC brands, especially in cosmetics and apparel, ship hundreds of SKUs using just a few optimized box styles.

You can analyze packaging dimensional weight breaks to stay under carrier thresholds. You can also use modular inserts to create snug fits without custom boxes per SKU. And if you want to get deeper into how dimensional weight impacts cost and how to optimize box sizing across your supply chain, here’s a detailed blog that breaks it down.

Design packaging “tiers” include small (1-2 items), medium (3-4), large (bulk/full sets).

So you can rely on stock sizing for volume and use branding layers (like sleeves) to differentiate.

Imagine a skincare company using three box sizes, one for single-item refills, one for bundled kits, and one for subscription packaging boxes. With custom inserts and consistent exterior branding, these three boxes serve dozens of SKUs, at scale.

What About Branding? What About Cost?

These are valid questions. Here is how experienced brands address them:

Branding

Your branding doesn’t come solely from the outer packaging. It comes from print consistency, clever use of color or white space, and internal details like branded tissue, sleeves, stickers, or QR codes.

A standardized box doesn’t mean a boring one. Mailer boxes with clean kraft prints still feel premium when designed thoughtfully.

Cost

Custom packaging does not automatically mean expensive. Many packaging suppliers in US now offer lower MOQs (as low as 250 units) with competitive pricing.

- Strategic customization helps you save on:

- Damage-related returns

- Dimensional weight penalties

- Labor time at the packing station

- Storage footprint

- Short answer: You are not choosing between “affordable” and “custom.” You are actually optimizing for total cost across the system.

Here’s What a Real Packaging System Looks Like

Different products move through your system in different ways. A hoodie doesn’t travel like a candle jar. A perfume set isn’t packed like refill pouches. That is why businesses don’t think in terms of “a packaging box”, they think in terms of components. The primary box, the insert, the wrap, and the label all change depending on what is being shipped and how it is meant to arrive.

Here are some examples of products and how their packaging systems are typically structured:

Packaging Breakdown

| Product Type | Primary Box | Insert/Modular Element | Branding Layer |

|---|---|---|---|

| Hand cream (single unit) | E-flute die-cut mailer | None | Printed exterior + sticker |

| Perfume set (gift box) | Tuck-top rigid mailer | Custom foam cradle | Kraft sleeve + QR code |

| Hoodie (folded apparel) | Standard mailer box | Tissue wrap | Printed label |

| Bulk B2B order (12 candles) | 275# double-wall RSC box | Kraft divider | Exterior shipping label |

| Ecommerce refill pouches | Padded kraft mailer | None | Printed insert card |

With a system like this, you cover:

- Direct-to-consumer retail

- B2B fulfillment

- Gifting

- Subscription

- Refill programs

All without bloating your packaging SKUs.

When Products Are Too Different to Standardize

Of course, not every business can consolidate this cleanly. If you ship everything from fragile glassware to soft apparel to hard goods, you will need more variation.

In these cases, you can consider:

- Flexible packaging for soft or odd-shaped items

- Multi-depth mailers that adjust height based on contents

- Nested inserts that stack or fold into each other

- Custom die cut packaging boxes to tailor to fragile or uniquely shaped products

- Hybrid model: use stock sizes externally with fully custom internal cushioning

A personalized approach is especially important in multi-SKU kits, seasonal collections, and marketplaces where unboxing experience matters as much as protection.

A Quick Tip on How to Get Started Without Overcomplicating It

You don’t need to overhaul your entire packaging operation overnight.

Start here:

- Pull dimensional data for your top 20 SKUs.

- Cluster them into fit ranges (e.g., 4x4x4–6x6x6).

- Choose 3–4 box sizes that serve 80% of your products.

- Add 1 custom insert per box that can adapt to product changes.

- Review your shipping data for dimensional weight red flags.

- Run a mock fulfillment scenario and see where time and materials are saved.

This system builds clarity before you go into design or print.

Let UCanPack Help You Build the Skeleton of Your Packaging System

You already know your product line is diverse. But your packaging doesn’t need to be chaotic.

With UCanPack, you get access to:

- Made-in-USA custom packaging boxes in any size or structure

- Rapid turnaround times with low MOQs

- Pre-scored dielines to simplify design

- Structural support for inserts, dividers, and protective elements

- Supply chain knowledge that makes packaging more than just a box, it becomes a part of how your business works

Want to get smarter about how your products move through the world? Let’s map out the right-sized system that does justice to every product in your line.

Sure, one size doesn’t fit all but one system can!