Stop Shipping Air: Understanding Dimensional Weight & Packaging Size Optimization

Introduction: Why Your Box Size May Be Costing You More Than You Think

Every business that ships products eventually hits the same realization that box size affects a lot more than just how your packaging looks. It has an impact on your shipping costs, your storage requirements, and your margins across the board.

Shipping carriers like FedEx and UPS calculate rates based on more than just actual weight. They use something called dimensional weight in packaging, which factors in the volume your box occupies in a truck or airplane. The larger the box, the higher the chargeable weight, even if the product inside is lightweight.

Global logistics data reveals that freight transport makes up around 8% of greenhouse gas emissions and up to 11% when including warehousing and ports. This highlights how inefficient packaging affects cost and carbon footprint alike.

If your business ships even a few hundred boxes a month, the dimensions of each carton can change your bottom line. Optimizing packaging box size becomes more than design concern. It becomes a strategic move to improve margins and streamline distribution.

In this guide, we will look deeper into dimensional weight, walk through packaging size optimization, and share practical steps to right-size every shipment. So you save on cost and space, while boosting operational performance.

Ready to unravel what makes packaging smarter? Let’s begin with the fundamentals.

What Is Dimensional Weight and Why It Exists

Dimensional weight (DIM weight) is the pricing method used by major carriers like FedEx, UPS, and DHL to account for space taken up in transit. Instead of charging purely by physical weight, carriers calculate a “chargeable weight” depending on how much volume a box occupies in relation to its actual weight.

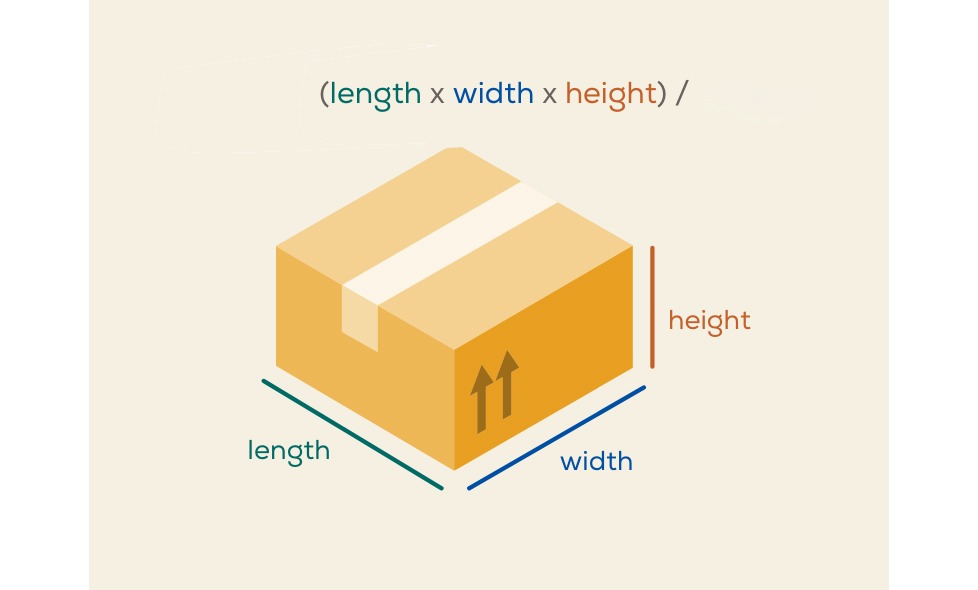

The dimensional weight formula is simple:

DIM weight = (L × W × H) ÷ DIM divisor

The DIM divisor varies depending on the carrier and service type. For example, UPS uses 139 for domestic services. So, a box measuring 20" × 14" × 10" with an actual weight of 5 lbs would be billed as:

(20 × 14 × 10) ÷ 139 = 20.14 lbs (chargeable)

That is a 15-pound difference. Multiply that across a month’s shipments, and you start to see why packaging dimensions carry weight, literally and financially.

Dimensional pricing was introduced to make up for underutilized cargo space. A packaging box of pillows costs less to ship than a box of dumbbells, but takes up more truck space. Carriers needed a way to charge based on volume, not just mass. DIM weight solved that.

It also pushed businesses to rethink their box choices, making packaging size a cost lever, not just a design detail.

Where Packaging Size Optimization Comes In

When you are shipping products daily, small misalignments in box sizing multiply into bigger costs. Packaging size optimization is not just a cost-cutting tactic; it is a supply chain efficiency play.

Here is what smart businesses actually look at when optimizing box sizes:

- Product-to-Box Volume Ratio. Every extra inch of empty space adds to your chargeable volume. The goal isn’t just fit, it’s efficient fit.

- Void Fill Requirements. Less space around the product means less filler. That reduces both material use and packing time. You can also check out die-cut mailer boxes, which are designed to reduce internal movement and eliminate the need for excess cushioning.

- Standardized Packaging Dimensions. Optimized sizing makes it easier to stack, store, and pick boxes efficiently, especially in 3PL or high-volume warehouse settings.

- Shipping Method Compatibility. Either you are shipping air or ground, dimensional weight charges kick in above certain thresholds. The right packaging dimensions can help you stay under those limits.

Customer Unboxing Experience. Oversized packaging boxes with excess padding create frustration. Right-size packaging improves both perception and practicality.

If you are in ecommerce, the stakes are even higher. From fulfillment center storage fees to last-mile delivery, packaging inefficiency compounds fast. Optimizing packaging box dimensions is all about how well your system moves from shelf to ship.

Box Size vs Product Size: Why They’re Rarely the Same

There is a common assumption that your box should match your product. Sounds logical. But in real-world packaging, things are far more layered.

Surely, products do not ship by themselves. They require cushioning, inserts, sometimes documentation, sometimes seals. What you are packing may be small, but what protects it, moves it, and helps it arrive in perfect condition takes up space. That space becomes part of your box.

Let’s say you are shipping a set of ceramic mugs. You are not just boxing the mugs. You are boxing air pockets around them, dividers between them, protective padding beneath them, and maybe even branding on top. And if those mugs are going into a warehouse, or being batch-packed with others for a subscription box, the outer box gets recalibrated again.

There is also the operational side. If your fulfillment team relies on pack stations or automation, your packaging box needs to be quick to assemble and efficient to close. That might mean tweaking its size slightly to save seconds, which adds up fast when you're shipping hundreds of orders a day.

And then there is the durability factor. Some items need thicker board strength or structural reinforcement. That is where box size and box strength start to influence each other.

So when a box seems “too big” or “slightly oversized,” it is often for a reason. Not because of bad design, but because that extra bit of space supports performance, across protection, labor, and transit reliability.

Packaging for Ecommerce and Warehouse Logistics

If your packaging boxes move through both warehouses and ecommerce channels, packaging size becomes more than a design detail. It becomes operational leverage.

Right size packaging supports efficiency across three key areas including:

- Warehouse Handling: Standardized box dimensions stack better, shelve faster, and move more predictably across conveyor systems. Whether you use a third-party fulfillment partner or manage your own inventory, packaging box size directly impacts speed and accuracy.

- Shipping Alignment: When your packaging dimensions match carrier expectations, you avoid unnecessary dimensional weight charges. That means fewer surcharges and more predictable freight bills.

Brand and Customer Experience: A box that is too big creates waste and frustration. Too small, and it can damage the product. Getting the balance right is key, especially in ecommerce packaging where unboxing is part of your product story.

If your team is already moving toward automation or scaling SKUs, investing in custom packaging boxes can bring that extra layer of precision. With the right dimensions baked into the design, you reduce touchpoints, trim packing time, and make inventory handling more intuitive, especially in high-volume environments.

Here is a quick snapshot of what optimized packaging achieves:

| Factor | Impact When Optimized |

| Packaging box dimensions | Reduces space usage in storage & transit |

| Right size packaging | Decreases void fill, lowers material cost |

| Box uniformity | Simplifies stacking, labeling & automation |

| Carrier charge thresholds | Helps avoid DIM weight surcharges |

| Customer handling | Improves experience and reduces return rates |

If you ship hundreds of packages a week, these small efficiencies stack up fast, and help your whole system move cleaner, faster, and cheaper.

Want to See Packaging Optimization in Action? Let’s Talk

If you have made it this far, you already understand how packaging box size shapes more than just shipping rates. It influences how fast your team packs orders, how well your warehouse uses space, and how customers experience your product at the time of delivery.

These are real, practical details. And that is where packaging stops being a background task and starts becoming part of how your business runs.

At UCanPack, we work with businesses to build packaging box sizes that really fit. Your product, your process, and your daily volume. If you are trying to reduce air in your shipments or bring consistency to your packaging, we can help you test, scale, and optimize without the guesswork.

Let’s figure out what the right packaging box looks like for your operation and finally stop shipping air!