UCanPack Blog

Costly Packaging Mistakes SMEs Overlook and Simple Ways to Fix Them

Imagine this scenario. Your product which is handcrafted, priced with care, gets carefully packaged into a standard brown box. A week later, a customer dings you for “more packaging than product.ReadMore

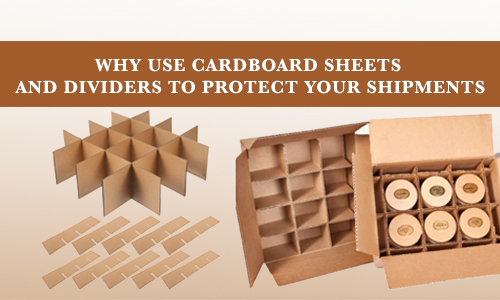

How Cardboard Sheets and Dividers Protect Shipments and Build Brand Trust

A box alone never tells the full story of safe shipping. Every business that packs and ships knows the uneasy moment before a delivery reaches its customer. Will everything inside arrive the way it left? This is where protective packaging earns its reputation. While most conversations center on box strength or outer packaging, the real heroes of safe transit often stay hidden inside the box: corrugated cardboard sheets and shipping box dividers.ReadMore

Think Local or Go Global? Practical Insights on Domestic and Overseas Packaging Suppliers

Imagine this. A growing business lands a major order and requires packaging supplies that fit both brand and budget. In fact, a recent KPMG study found that over two thirds of large U.S. firms plan to move supply operations closer, shifting nearly 10 percentage points toward North or South America, driven by a desire for control, quality, and agility. The decision seems simple at first. But sourcing never follows a straight line.ReadMore

Measuring Boxes 101: Inside vs Outside Dimensions & Getting the Perfect Fit

When you are packing a product, especially one that’s fragile, oddly shaped, or meant to impress the end customer, the first thing you measure shouldn’t be the box. It should be the function. What exactly does that packaging box need to do once it’s filled, sealed, and on its journey?ReadMore