How to Choose the Right Box Style (Not Size): The Ultimate Guide for Non-Packaging People

Introduction

When sourcing packaging, choice often stops at size. But packaging box style determines how well products ship, how they look on arrival, and how smoothly your team works. This guide skips the supply-chain jargon and zeroes in on matching shape, structure, and unboxing experience with your real-world needs.

Want to know a fact? 72% of consumers report that attractive packaging influences their purchase decisions, and about 67% feel paper or cardboard packaging makes a product seem premium. That means a decision about box style can shape both your fulfillment efficiency and customer perception.

We will explore the most common packaging box styles, explain why form matters more than brand names, and give you a clear path to choosing packaging boxes that support your product, protect your margins, and work well with your operations.

Ready to match your product with the right structure? Let us begin.

Breaking Down the Most Common Box Styles

There are thousands of packaging box variations in the market, but most corrugated packaging in ecommerce and retail supply chains revolves around a few structural standards. Choosing the correct one has less to do with what “looks good” and everything to do with efficiency, cost-per-unit, and how your product behaves during handling and transit.

Here are the primary technical styles you should know:

RSC (Regular Slotted Container)

Best for: Uniform items, bulk shipping, warehouse fulfillment

Structure: All flaps have the same length. Outer flaps meet at the center when closed.

Why it works:

- Highly material-efficient

- Compatible with automation (e.g., case erectors)

- Ships flat and stores easily

- Works with standard stock box sizes

This is the industry’s most commonly used shipping box and for good reason. It optimizes internal volume vs. material use and integrates well into high-speed fulfillment environments.

Die Cut Mailers (Indestructo-Style)

Best for: Small-to-medium-sized DTC products, subscription kits, premium packaging

Structure: One-piece box with attached lid and locking flaps, custom die-cut to fit.

Why it works:

- Tamper-resistant design

- Minimal void fill needed

- Easier unboxing experience

- Offers structural integrity even without tape

Die cut mailers excel where presentation and protection intersect. If your brand cares about branded experiences or protective single-unit shipping, this style gives you control without requiring custom inserts.

Literature Mailers

Best for: Documents, print media, flat products like folders or apparel

Structure: Side-fold design with rollover edges for stiffness

Why it works:

- Easy to assemble without tape

- Strong edge rigidity for flatter products

- Professional presentation without excess packaging

- These are ideal when branding and form factor are more important than internal padding. If you ship books, media kits, or anything that should arrive crease-free, this is the perfect box for you.

Once you have narrowed your options to the standard box styles used across industries, it becomes easier to align function, cost, and brand impact. And if you want to understand in-depth about such common boxes, you can check out this blog:Mailer Boxes, Shipping Boxes, or Literature Mailers: How to Choose the Right One for Your Business.

How Function Dictates Form in Packaging

You don’t need to be an engineer to make smart packaging choices. You just need to ask the right questions about what your product actually demands. These three functional filters can guide your entire box style decision, without overthinking materials, sizes, or design.

Is it shipping something fragile?

Protective inserts, padding clearances, and crush resistance become non-negotiables. In this case, your choice isn't just about size. It is all about designing around shock absorption. The structural integrity of the box matters, and so does the ability to secure cushioning or dividers in place

Will it be displayed on a shelf or opened in front of a customer?

If yes, the style must do more than protect, it must present. Here, things like seamless closures, clean die-cut edges, and coated finishes often add more value than extra padding. Also, ease of unboxing becomes just as important as stacking efficiency.

Does the product require inserts or cushioning?

The decision here should flow from your internal packaging needs. Are you using foam cutouts, paper wraps, molded trays? Your packaging box must be designed to hold those inserts efficiently. Even a slightly wrong box depth can increase damage risk and shipping costs.

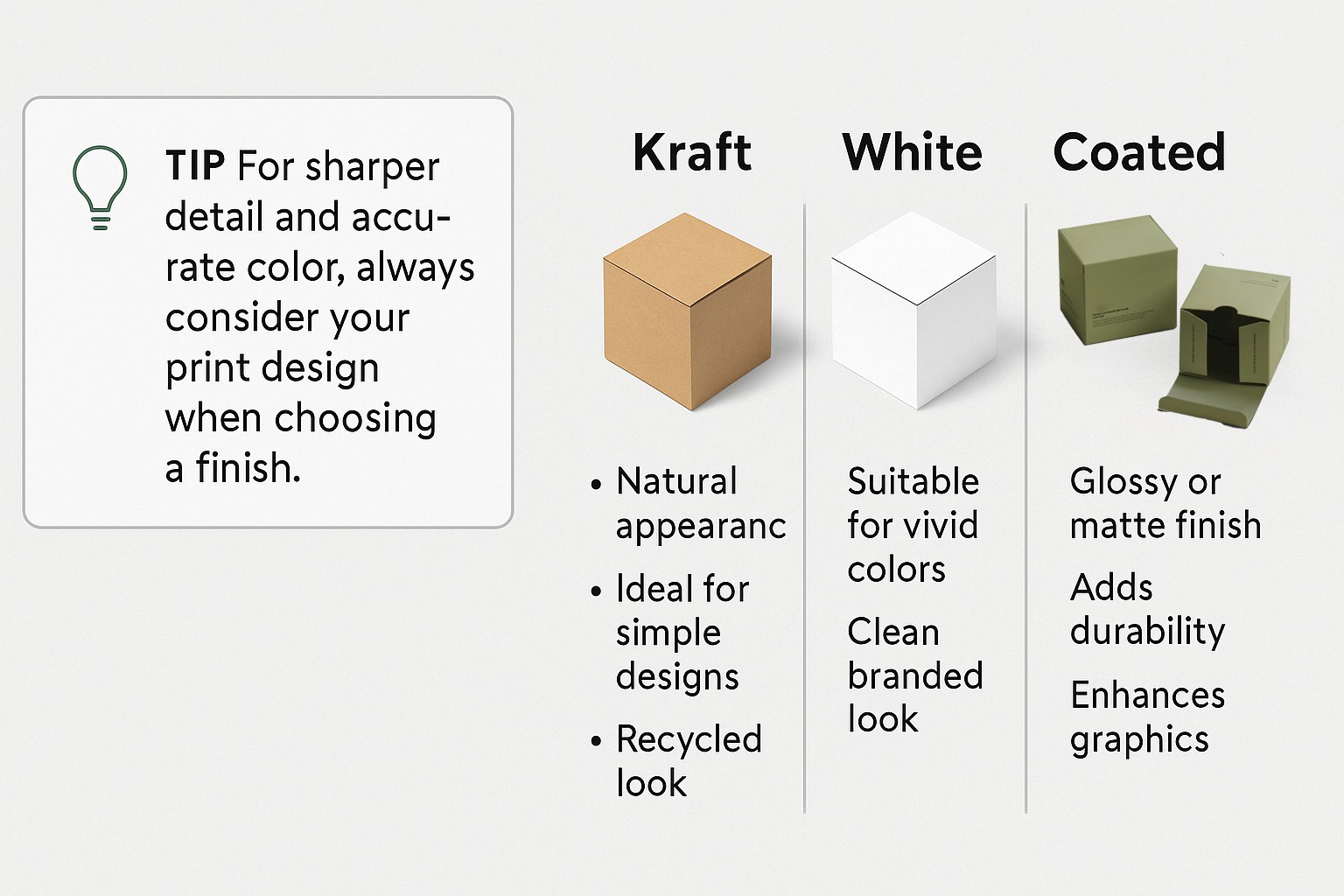

When to Choose Kraft, White, or Coated Finishes

Surface finish is not just a design detail. It impacts how your packaging prints, how your brand looks in unboxing photos, and how durable the box feels when it reaches the customer.

- Kraft Boxes

Kraft is often chosen for its natural, earthy appeal. It works well with bold, high-contrast designs, especially black, deep blues, or saturated reds. But colors like pastels, greys, or yellows may appear muted or shift slightly when printed. That is because kraft absorbs ink differently than white substrates and does not support white ink. Any white space in your design will show up as raw kraft.

This finish also appeals to brands that want a minimalist or eco-conscious aesthetic. And it generally hides scuffs and handling marks better in transit.

- White Boxes

White finishes are versatile and ideal for vibrant, color-heavy branding. Logos that use multiple hues or require fine print detailing show up more accurately on white. If your design includes gradients or soft tints, white will ensure they print with fidelity.

White boxes also give a more “retail ready” look for shelf display, and they allow for subtle textures like matte or glossy coatings to add polish.

- Coated or Laminated Boxes

Coated finishes offer durability plus visual impact. They are great for heavy ink coverage, full-panel designs, or premium product lines that need extra protection from moisture, dust, or handling wear. Coatings also allow effects like spot gloss, UV, or metallic overlays, useful for high-end cosmetics, electronics, or subscription boxes.

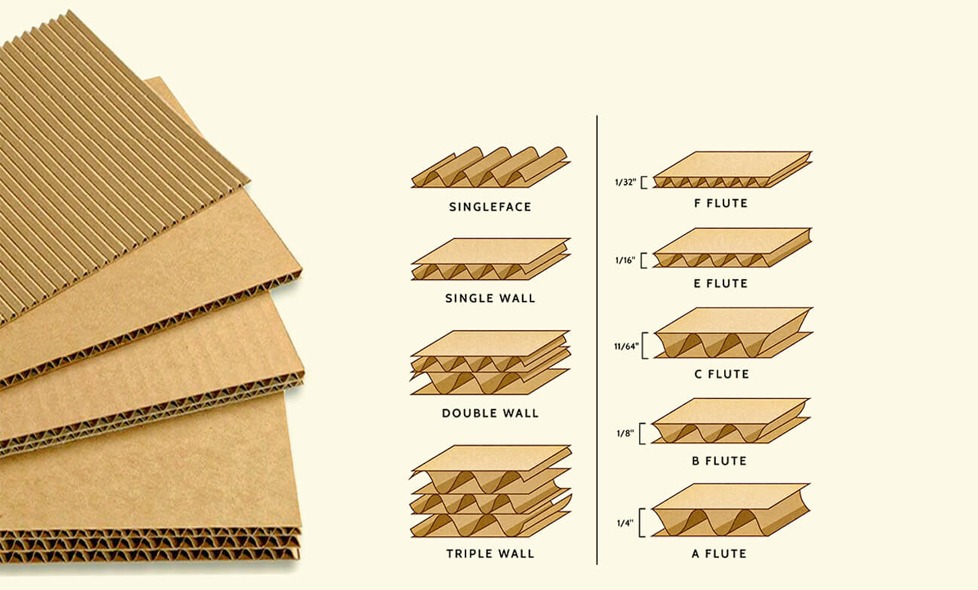

Don’t Mix Up Style with Strength: What Actually Impacts Durability

It is easy to assume that a “strong-looking” box is a strong box. But durability in packaging is not about visual thickness, color tone, or flap design. It is about structural engineering and material specs. The box style has great importance, but it’s the board grade, flute type, and construction quality that define how much impact or pressure a box can handle during storage and transit.

For example:

- A sturdy RSC box made with single-wall C-flute board (3/16") can often outperform a flashy die-cut mailer made from thinner E-flute (1/16") material, especially when it comes to stacking or pallet shipping.

- Double-wall construction (two layers of fluting) adds significant compression strength but increases the box’s footprint and cost, which may not be necessary for lightweight items.

What you are shipping, how far it is traveling, and how it is being handled along the way should shape your material and strength decisions.

Want to keep it simple? Most ecommerce packaging for retail performs well with 32 ECT single-wall corrugated boards but if you are shipping fragile items or sending wholesale corrugated boxes through long freight routes, you’ll want to go sturdier.

Final Checklist Before You Order

Choosing the right packaging box style becomes easier when you pause to ask the right questions, before hitting “order.” This quick checklist can help you align design with real-world usage, so you are not second-guessing after production.

- What is the primary function of this box?

Are you shipping, shelving, or handing off in-person? Every application changes the ideal box profile. - Have you tested fit and closure with your actual product?

A few physical samples go a long way in avoiding sizing surprises, especially for products with irregular dimensions. - Will the box require inserts, padding, or tamper evidence?

These needs often dictate whether you go with a mailer, RSC, or something more custom. - Is the unboxing experience important for your brand?

If yes, factor in interior design, printing finish, and how easy the box is to open and reseal. - Do your suppliers or fulfillment partners have box constraints?

It is worth checking if they prefer certain styles, dimensions, or board grades. Streamlined collaboration can reduce handling errors. - Have you looked at board strength, not just box shape?

The style supports function, but the strength supports weight. Both matter.

If you have considered all these, you are not just ordering packaging. You are making a decision that supports your brand, your team, and your supply chain.

Want to Explore Box Styles in Real Life? Let’s Help

You do not need to figure it all out on paper. Sometimes, holding a sample in your hand or seeing how your product fits in a real box makes all the difference. If you are rethinking your current packaging or sourcing for a new launch, we make it simple to experiment and customize, without jumping through hoops.

And if you are ready to explore style options or want to test a few samples, we’ve got you.

AtUCanPack, you can browse die-cut mailers, standard RSC boxes, or custom printed solutions in white and kraft finishes. All designed with performance and presentation in mind.

Let’s get your packaging working harder for your business!