How to Choose the Right Flute Type in Corrugated Boxes

Selecting the right cardboard box for packaging involves considering several critical factors to ensure your product is well-protected during storage and shipping. Boxes serve a vital role, not only in protecting products but also in building a company's brand identity and delivering a memorable unboxing experience for customers. Cardboard boxes are also selected based on its sustainability and shipping requirements.

These considerations encompass:

Box Type: Selecting the right type of cardboard box is a crucial decision in the realm of packaging. There are two primary options to consider: paperboard boxes, often referred to as product boxes, and corrugated cardboard boxes, known for their strength and durability.

Paperboard Boxes (Product Boxes): Paperboard boxes are known for their slim profile, typically measuring 0.010 inches or less in thickness. Paperboard thickness is typically measured in either grams per square meter (GSM) or points. The thinnest white paper falls within the range of 35-55 GSM, commonly found in newspapers and magazines. Standard office paper falls between 90-120 GSM and is widely used for various purposes. Promotional posters often use paper weighing 130-250 GSM. For high-quality brochures and magazines, heavier yet flexible cards ranging from 260-300 GSM are suitable. The thickest and sturdiest paper, with a weight of 350-450 GSM, is ideal for making product boxes, business cards and invitations.Despite their thin appearance, they offer remarkable flexibility, sturdiness, and an elegant look. These qualities make them a popular choice in industries where aesthetics and durability are paramount, such as cosmetics, bakery goods, toiletries, and clothing.

Ensuring the durability of the chosen paperboard box is vital to withstand the rigors of shipping. As products traverse from manufacturer to consumer, they encounter diverse challenges, including mechanical stress, temperature variations, and environmental factors. Consequently, safeguarding products from potential damage during transit becomes paramount. The durability of a paperboard box functions as a protective barrier for the enclosed items, shielding them from external forces like handling impacts, transportation vehicle vibrations, and harsh weather conditions. Boxes lacking in durability pose a risk to the products they contain, potentially resulting in breakage or spoilage during the shipping process.

Corrugated Cardboard Boxes (Shipping and Mailer Boxes): Corrugated cardboard boxes are known for their thickness and strength. These robust boxes are versatile and find applications in various scenarios, from mailers and pizza boxes to shipping, moving, and storage containers. They excel in withstanding the rigors of transit and providing superior protection to their contents.

The choice between paperboard and corrugated cardboard hinges on the specific needs of your product and the level of protection required. Paperboard boxes shine in presenting products elegantly, while corrugated cardboard boxes prioritize strength and durability, making them ideal for shipping and protecting items in transit.

Types of Corrugated Cardboard in Box Manufacturing: Corrugated cardboard consists of flat liners with wavy layers known as flutes sandwiched in between.

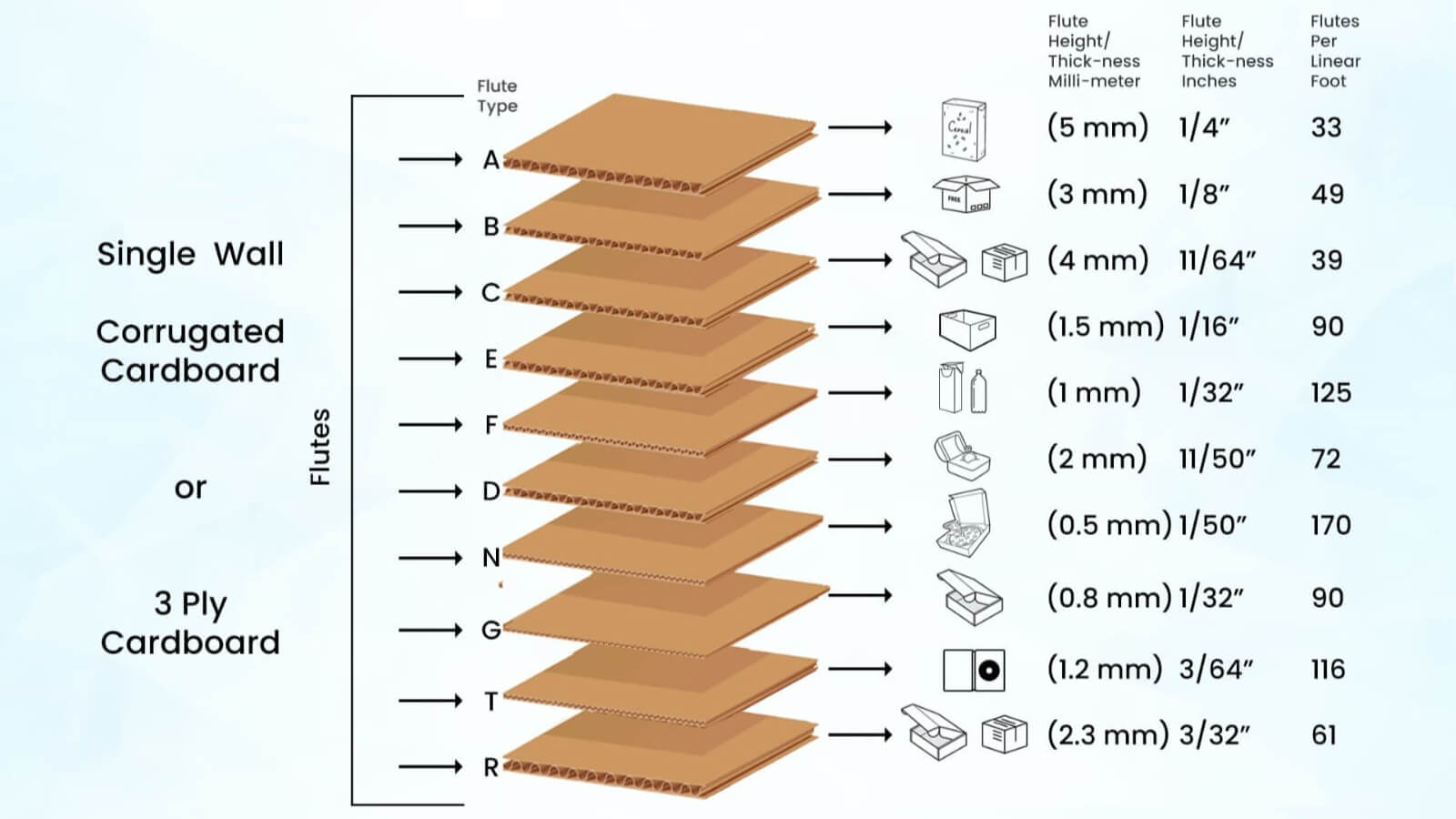

These flutes come in various types (A, B, C, E, F, D, N, G and T), each suited for different product needs. Smaller flutes generally offer enhanced crush resistance and printability, while larger flutes provide better cushioning and stacking strength. The choice between them depends on specific packaging needs and the desired level of protection for the enclosed products. The number of flutes per square foot has a significant impact on cardboard strength.

|

Flute Type |

Flute Height/ Thick-ness Inches |

Flute Height/ Thick-ness Milli-meter |

Flutes Per Linear Foot |

Common Uses |

|

A Flute |

1/4” or 0.25 inches |

5 mm |

33 |

Thickest and strongest, compression resistance, cushioning properties (storage boxes, fragile items packaging) |

|

B Flute |

1/8” or 0.125 inches |

3mm |

49 |

Padding, displays, inner packaging, can be printed (mailer boxes, retail packaging and cardboard sheets) |

|

C Flute |

11/64” or 0.17 inches |

4mm |

39 |

Heavier items, can be printed (shipping boxes, furniture packaging, glass packaging, Dairy packaging) |

|

E Flute |

1/16” or 0.06 inches |

1.5mm |

90 |

Retail packaging, less strong, can be printed (mailer boxes, displays, ballot boxes, pizza boxes) |

|

F Flute |

1/32” or 0.031 inches |

1mm |

125 |

Thinnest and flexible, sleek appearance (jewelry boxes, displays, shoe boxes, cosmetic packaging) |

|

D Flute |

11/50” or 0.22 inches |

2mm |

72 |

Thicker and stiffer (take out boxes, pizza boxes, food packaging and pallets) |

|

N Flute |

1/50” or 0.02 inches |

0.5mm |

170 |

Thin, lightweight, smooth (cosmetic, jewelry packaging, printing) |

|

G Flute |

1/32” or 0.031 inches |

0.8mm |

90 |

Thin and lightweight (pizza boxes, cake boxes, cereal boxes) |

|

T Flute |

3/64” or 0.046 inches |

1.2mm |

116 |

Thin, smooth, flexible (retail displays,bakery boxes, mailers used to pack dvd,cd, books) |

|

R Flute |

3/32” or 0.090 inches |

2.3mm |

61 |

Thin, strong, smooth, better print surface, crisper creasing (mailer boxes, retail packaging, cardboard sheets) |

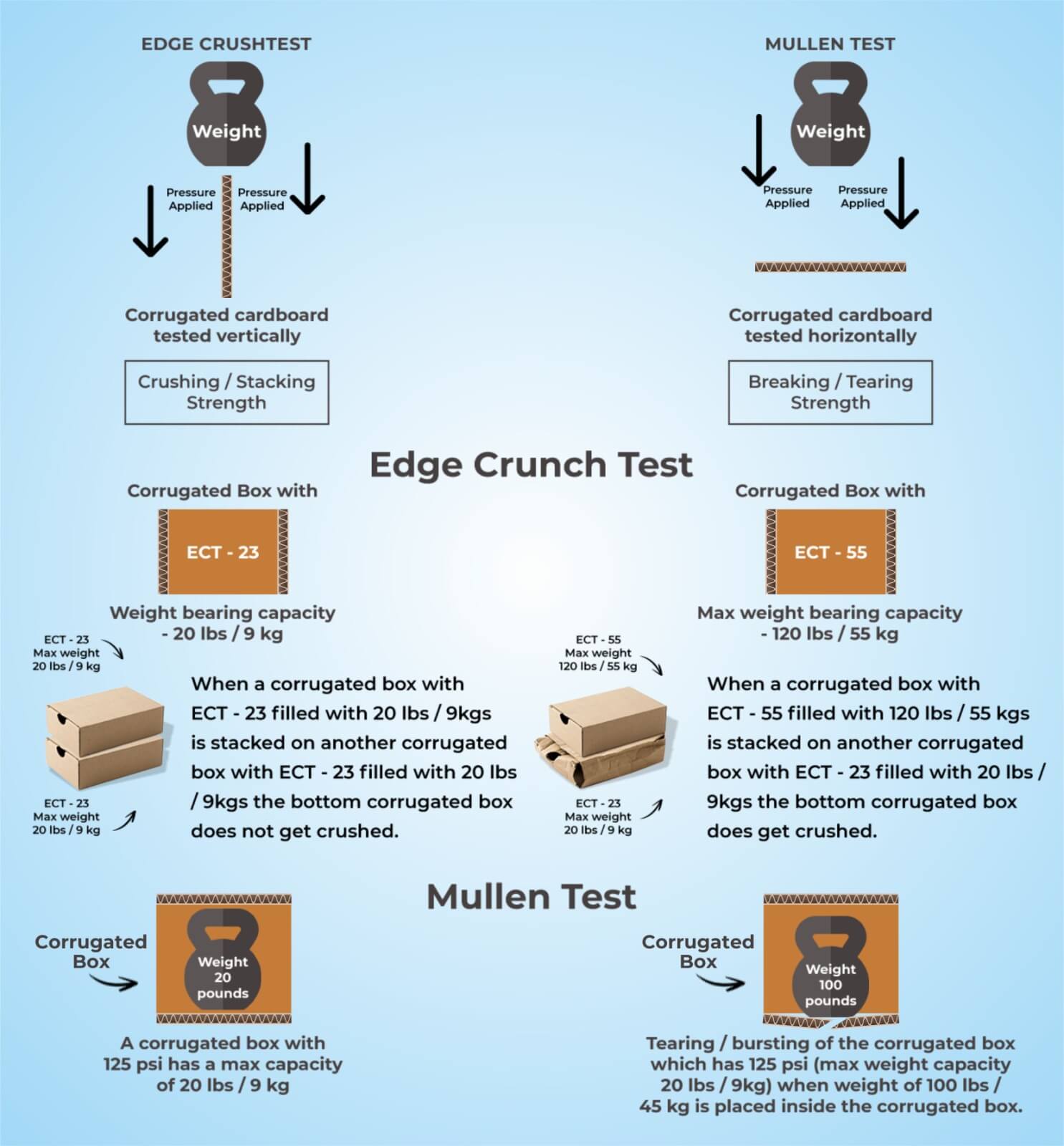

Product Weight: Consider the weight of your product when choosing the type of cardboard. This will influence whether you need a single-wall, double-wall, or even a triple-wall box to provide the necessary strength and durability for safe transport and handling. The weight capacity of a single wall, double wall, triple wall box is determined by its Edge Crush Test (ECT) rating and The Mullen Test. Edge Crush Test is the testing of a cardboard flute in vertical position, which determines the stacking strength of the box. The Mullen test is testing how strong the box is to resist puncture.The Mullen Test rating is measured as pounds per square inch (psi). Nowadays, most of the companies use Edge Crush Test in the selection of the boxes. A box made with 200# The Mullen Test is stronger than a box made with 32 ECT.

Single Wall Boxes: Single-wall boxes feature one corrugated medium sheet sandwiched between two liner sheets. Basically Single wall boxes are made of 3-ply corrugated sheets. Single wall boxes are made of flutes A, B, C and E.These boxes are particularly popular among Small and Medium Businesses (SMBs) and find extensive use for shipping a range of items, including jewelry, beauty products, clothing, and small goods. Estimations of weight capacity for single-wall boxes rely on their ECT (Edge Crush Test) ratings and Mullen Tests, which assess strength and durability, ensuring their appropriateness for specific applications. Given the prevalent use of single-wall boxes by SMBs, comprehending their weight-bearing capabilities through rigorous testing is essential for streamlining packaging and shipping operations.

Double Wall Boxes: Double wall boxes consist of two corrugated sheets securely glued together, forming 5-ply corrugated sheets. These boxes find extensive use in the retail sector for the storage and stacking of items like vegetables, fruits, furniture, beverages, and pharmaceuticals. They are also utilized for moving purposes. Gaylord boxes, constructed from double-wall cardboard sheets, serve similar functions. Typically, double wall boxes are crafted using a combination of BC flutes, representing one layer of B flute and one layer of C flute. This combination offers an optimal balance of strength and cushioning. Various types of double-wall boxes, including BC, EB, BB, EC, BE, AC, AB and CC, are produced using specific cardboard flute variations. The strength of these double-wall boxes is dictated by the specific combination of cardboard flute types chosen in their production process.

Triple Wall Boxes: Triple-wall boxes are constructed from three corrugated sheets, typically employing 7-ply corrugated sheets. These boxes are primarily designed for heavy appliances, substantial furniture, and large, weighty components. Gaylord boxes, commonly used for palletization and stacking, are often crafted from triple-wall sheets. The most frequently used triple-wall combination comprises cardboard with BAC, AAC, and CAC flutes.The strength of these triple-wall boxes is influenced by the specific combination of cardboard flute types selected during the manufacturing process.

Here is the table that can help to choose the right box for the product by weight-bearing capacity:

|

TYPE OF WALL BOX |

POSSIBLE FLUTE TYPES |

ECT RATING (EDGE CRUSH TEST) |

MULLEN TEST (BURST TEST) |

MAXIMUM WEIGHT CAPACITY |

|

SINGLE WALL BOX |

B, C |

ECT 23 |

125 psi |

15/20 pounds |

|

SINGLE WALL BOX |

B, C |

ECT 26 |

150 psi |

25/35 pounds |

|

SINGLE WALL BOX |

B, C |

ECT 29 |

175 psi |

45/50 pounds |

|

SINGLE WALL BOX |

B, C, A, E |

ECT 32 |

200 psi |

55/65 pounds |

|

SINGLE WALL BOX |

B, C, A |

ECT 40 |

225 psi |

75/80 pounds |

|

SINGLE WALL BOX |

B, C, A |

ECT 44 |

300 psi |

85/90 pounds |

|

SINGLE WALL BOX |

B, C, A |

ECT 55 |

326 psi |

115/120 pounds |

|

DOUBLE WALL BOX |

BC, AC |

ECT 44-48 |

275 psi |

95/100 pounds |

|

DOUBLE WALL BOX |

BC, AC |

ECT 51-55 |

350 psi |

115/120 pounds |

|

DOUBLE WALL BOX |

BC, AC |

ECT 61-65 |

400 psi |

135/140 pounds |

|

DOUBLE WALL BOX |

BC, AC |

ECT 71-75 |

500 psi |

155/160 pounds |

|

DOUBLE WALL BOX |

BC, AC |

ECT 82 |

660 psi |

180/185 pounds |

|

TRIPLE WALL BOX |

BAC, AAC |

ECT 67 |

700 psi |

230/240 pounds |

|

TRIPLE WALL BOX |

BAC, AAC |

ECT 80 |

900 psi |

250/260 pounds |

|

TRIPLE WALL BOX |

BAC, AAC, CAC |

ECT 90 |

1100 psi |

270/280 pounds |

|

TRIPLE WALL BOX |

BAC, AAC, CAC |

ECT 112 |

1300 psi |

290/300 pounds |

Gaylord boxes are constructed using various combinations of cardboard flutes, including double wall, triple wall, four wall, five wall, and seven wall configurations.

Dimensions of the Product: The dimensions and configuration of your product are pivotal factors in determining the appropriate box size and style. The box should be well-matched to your product's size and shape to avoid wasted space and ensure a snug fit. Precisely measure the length, width, and height of your product; these measurements are fundamental in selecting a box. In the United States, standard box measurements are typically expressed in inches, reflecting the country's predominant use of the Imperial system of measurement. These standardized box dimensions play a crucial role in various industries, from packaging and shipping to storage and retail. The common box sizes help streamline logistics, as they are compatible with pallets, shelving units, and transportation containers. This consistency in sizing not only enhances efficiency but also facilitates uniformity in pricing and labeling. It simplifies the process of selecting the right packaging solution for businesses, ensuring compatibility with industry standards and regulations while accommodating diverse product sizes and shapes.

Usage of the Box: When selecting a box, it's essential to factor in its intended purpose, as this can greatly vary and impact your choice. Boxes serve various functions, including storage, shipping, moving, or display. Each purpose demands specific characteristics from the box. Storage boxes require durability and stacking ability to efficiently organize items. Shipping boxes need to withstand the rigors of transportation and protect their contents. Boxes for moving should be easy to handle and stack securely. Display boxes prioritize aesthetics and presentation to showcase products attractively. The choice of the box type also takes into account whether the products require additional inserts to protect them during transit. These inserts can come in various forms, including foam, paperboard, anti-slip cardboards, corrugated cardboards, plastic inserts, promotional materials, or other essential information. By understanding the distinct requirements associated with these purposes, you can make an informed decision when choosing the most suitable box for your needs, ensuring optimal functionality.

Branding and Printing: When it comes to customization, printing, and branding, it's essential to choose an appropriate surface. One of the primary considerations in this regard is the brand's logo and the size of the print. The packaging itself can be seen as a canvas for incorporating a company's logo and other branding elements. The dimensions and positioning of these visual elements play a pivotal role in effectively conveying the brand's message. A well-designed package with a prominently featured logo can significantly strengthen brand recognition and recall, thereby reinforcing the company's image in the customer's mind.

When businesses embark on the journey of selecting the perfect packaging for their products, they must carefully consider numerous factors, all of which are intricately tied to their ultimate objective: creating a memorable impression and cultivating brand loyalty. Among these considerations, the brand's logo and print size take center stage. The packaging serves as a platform for showcasing a company's logo and other branding elements. The size and placement of these visual cues are vital for conveying the brand's message effectively. A thoughtfully designed box with a prominently displayed logo can serve to bolster brand recognition and recall, thus solidifying the company's image in the customer's consciousness.

In essence, companies need to align their packaging choices with their overarching goals. Are they aiming to communicate notions of luxury and sophistication, environmental responsibility, or a sense of excitement and enjoyment? By gaining a deep understanding of their target audience and the emotions they aim to evoke, businesses can select the perfect packaging that resonates with their customers and reinforces their brand identity. Ultimately, the right choice of packaging becomes a potent tool for conveying the company's values and making a lasting impact on the customer's perception.

Boxes frequently function as conveyors of essential product details, which are occasionally imprinted directly onto the packaging. This information encompasses product specifications, usage guidelines, safety advisories, and even promotional content. Moreover, packaging may incorporate handling instructions, offering guidance to those involved in shipping, handling, and receiving the package, thereby safeguarding the product's well-being and preserving its condition throughout its voyage. These printed particulars not only offer valuable insights to consumers but also play a pivotal role in upholding the product's excellence and securing its dependable delivery.

Closure Method of the Box: When it comes to selecting the closure method for your packaging, it's important to consider your specific requirements and the nature of your products. There are several closure options available, including tape, glue, and interlocking flaps, and each has its advantages and best-use scenarios.

Tape Closure: Using tape for sealing your boxes is one of the most common and versatile methods. It's easy to apply and provides a secure seal. You can choose from various types of tapes, such as standard packing tape, reinforced gummed tape, or even custom-printed tape with your logo. This method is efficient and works well for a wide range of products.

Glue Closure: Glue provides a more permanent and tamper-evident seal. It's an excellent choice for products that require extra security or for boxes that will be subjected to rough handling during shipping. Glue closures are often used for high-end packaging, luxury products, or when you want to convey a sense of craftsmanship.

Interlocking Flaps: Interlocking flaps, sometimes referred to as tuck flaps or tab-lock closures, are ideal for packaging that will be opened and closed multiple times. They offer a convenient and resealable option. These closures work well for items like folders, portfolios, or presentation boxes. They are easy to open and close without the need for additional materials like tape or glue.

To make an informed decision, consider the following factors:

Product Nature: Consider the fragility and characteristics of your products; if they demand added protection, opting for a more secure closure method like glue may be appropriate. For items that are less delicate, tape or interlocking flaps may suffice. In certain cases, products require additional safeguarding within the box, and this is where various types of corrugated sheets come into play as inserts during transit. Corrugated sheets encompass several varieties, including single face boards, single wall boards, double wall boards, and triple wall boards. Single face boards, characterized by a single fluting layer and a smooth liner on one side, are frequently utilized as inserts within boxes. Their primary role is to create separation and ensure the protection of enclosed products, thus enhancing the packaging's safety standards. Meanwhile, single wall sheets, double wall sheets, and triple wall sheets are selected based on product weight, with heavier items often requiring their use as inserts.

Customer Experience: Consider the unboxing experience and the impression you want to leave on your customers. A well-designed closure method can enhance the overall perception of your brand.

Efficiency: Evaluate the efficiency of your packaging process. Some closure methods are quicker and more convenient than others. Choose one that aligns with your production speed and requirements.

Tamper Resistance: If tamper resistance is crucial for your products (e.g., pharmaceuticals or sensitive documents), then glue or tamper-evident tape may be necessary.

Finally, factor in the cost of materials and labor associated with each closure method. Some methods may be more cost-effective than others, depending on your volume and budget.

Unboxing Experience: Elevating the unboxing experience for your customers involves a thoughtful blend of elements that go beyond the product itself. Start with the box color, a powerful tool for reinforcing brand identity and setting the tone for the unboxing adventure. The color you choose should resonate with your brand's personality, creating an immediate visual connection. But why stop there? Infuse excitement by incorporating playful packaging elements like tissue paper, adding a touch of elegance and anticipation. Crinkle paper can amplify the joy, enhancing the tactile experience and offering a delightful surprise. Don't underestimate the impact of combining multiple items in one box, increasing customer excitement while providing an efficient and cost-effective shipping solution. Today, the unboxing experience is more than just a transaction; it's an essential part of customer satisfaction and engagement. Craft it with care, transforming an ordinary purchase into a cherished memory. The design, color, and materials used in your packaging, along with thoughtful elements like personalized notes, can create an emotional connection. Remember, customers are not merely buying a product, they're investing in a unique, unforgettable experience.

Environmental Effects on Products: When selecting the appropriate packaging, it's essential to consider the potential environmental effects on both the box and the product during transit. This consideration becomes particularly critical for industries dealing with sensitive items like food and medical products. Environmental factors such as temperature fluctuations, humidity, and exposure to contaminants can significantly impact the integrity and safety of these products. Choosing packaging materials and designs that offer adequate protection against these environmental variables is essential to ensure product quality and safety. By addressing these concerns proactively, businesses in the food and medical sectors can maintain the highest standards of product preservation and consumer well-being.

Regulations and Compliance : When making your packaging selection, it's vital to take into account the specific packaging standards and regulations within your industry. Ensure that the cardboard box you choose aligns with these industry-specific requirements, as they can vary significantly depending on your sector. Compliance with these standards not only guarantees the safe and lawful packaging of your products but also reflects your commitment to professionalism and quality. By staying informed and adhering to these regulations, you demonstrate your dedication to meeting the unique demands of your industry, enhancing product safety, and maintaining a strong reputation within your niche. It's a crucial aspect of responsible and effective packaging decision-making.

Shipping Cost of the Box: When considering the shipping cost of your package, optimizing space by efficiently packing multiple items together can significantly reduce shipping expenses. It's vital to evaluate the fragility or durability of your products, as this directly influences your packaging requirements. Additionally, take into account the dimensions and weight of the box, as these factors play a crucial role in determining the overall shipping cost. Strive to select packaging materials that strike a balance between durability and affordability.

To calculate the shipping cost of a package, various factors come into play:

Shipping Destination: The shipping destination is a fundamental factor. Whether you're shipping domestically within the US or internationally, it significantly impacts the cost. For domestic shipments within the US, there are typically eight zones, and the shipping cost increases with the distance from the point of origin.

Delivery Timeframe: The desired delivery time frame selected by the customer is another pivotal consideration. Shipping companies offer diverse delivery options, including:

- Same Day Delivery: The quickest service for same-day arrival.

- Next Day Select: Ideal for overnight shipments requiring swift delivery.

- 2nd Day Select: Packages reach their destination within two days.

- 3-Day Select: Suitable for less time-sensitive express shipments.

- Ground: Day-definite delivery, taking between 5 to 8 days. Note that some companies operate exclusively on business days, while others provide weekend delivery. Certain carriers also offer the option to hold packages for specified durations upon request.

Dimensional Weight (DIM): DIM weight, often referred to as DIM, determines the billable weight of the package. To calculate DIM, follow these steps:

- Measure the length, width, and height of the box, with the length being the longest side.

- Determine the actual weight of the box.

- Use the formula DIM = (Length x Width x Height) / DIM factor, where L represents length, W is for width, H is for height, and DIM is the dimensional weight.

- Different shipping carriers like UPS, USPS, FedEx, and DHL have their specific DIM factors.

- Round all measurements to the nearest whole number.

Each major shipping carrier employs specific DIM(Dimensional) formulas to determine shipping costs based on package size. Here are the formulas used by these carriers:

UPS:

- For Daily Rates: DIM weight = (Length * Width * Height) / 139

- For Retail Rates: DIM weight = (Length * Width * Height) / 166

- For countries using centimeters: DIM weight = (Length * Width * Height) / 5000

- The billable weight is the greater of the dimensional weight or the actual weight.

- Additional handling charges may be incurred for packages with dimensions where the longest side of the box exceeds 48 inches or the second-longest side of the box exceeds 30 inches.

- If the average weight of the box is greater than 50 pounds or packages over 50 pounds additional handling charges are added by UPS.

USPS:

- DIM weight = (Length * Width * Height) / 166

- USPS applies dimensional weight for packages larger than one cubic foot. The maximum actual weight allowed is 70 pounds.

- USPS stands out as the most cost-effective choice for shipping packages weighing less than 2 pounds, making it the overall economical option for domestic shipments in the United States.

FedEx:

- Using inches per pound: DIM weight = (Length * Width * Height) / 139

- Using centimeters per kilogram: DIM weight = (Length * Width * Height) / 5000

- Make sure to check size and weight restrictions.

DHL:

- DHL calculates cost based on volumetric weight, considering both actual and volumetric weight. The formula varies by transportation mode:

- For air freight: ((L x W x H, in centimeters) / 6,000) x number of packages

- For ocean freight: ((L x W x H, in centimeters) / 1,000) x number of packages

- For rail freight: ((L x W x H, in centimeters) / 3,000) x number of packages

- Density ratios may vary by location and carrier for road freight.

Keep in mind that each carrier may have its own terms, size restrictions, and weight limits, so it's essential to check their specific guidelines before choosing a shipping option.

Billable weight of the Box: Billable weight is a method employed by carriers to determine shipping costs per package, considering both the dimensional weight (dimensions like length, width, and height) and the actual weight of the shipment. The higher of these two weights is used as the billable weight for your shipment, which in turn dictates the applicable shipping rate.

Additional Surcharges: Certain shipping companies may apply extra charges to shipments based on various factors.

- Residential surcharges

- Deliveries to rural or remote areas

- Address inaccuracies

- Oversized packages

- Incorrect weight or dimensions provided for the box

- Adherence to packaging regulations such as using strapping or tape for sealing

- Peak-season surcharges

- Incorrect placement of the shipping label (if not on the longest side of the box)

- Box dimensions and shapes

- Overweight packages

- Delivery time selection

All of these elements collectively impact the overall shipping cost of a package. Businesses and customers should carefully consider these factors when planning their shipments.

Sustainability of the Box: Prioritizing environmental sustainability within your business entails opting for easily recyclable cardboard boxes. Embracing eco-friendly or recyclable packaging aligns with your company's sustainability objectives and resonates with environmentally-conscious customers. By choosing cardboard boxes that can be readily recycled, you contribute to reducing environmental impact and waste. This commitment not only demonstrates your environmental responsibility but also appeals to a growing market of eco-conscious consumers who actively seek products packaged in environmentally-friendly materials. It's a proactive step toward building a positive brand image, fostering customer loyalty, and ensuring your business aligns with the values of sustainability and responsible resource management.

In summary, taking into account factors like product fragility, dimensions, weight, shipping destination, and suitable packaging materials is essential when choosing the right box for a product. These considerations work together to determine the best packaging solution, ensuring the product's safe delivery while reflecting the brand's identity. A thoughtful evaluation of these factors enables businesses to make informed decisions, leading to efficient and protective packaging solutions that meet their needs.