Mailer Boxes vs. Envelopes: What's Best for Your Business

Introduction to Packaging Options

The significance of packaging in representing a brand cannot be overstated. The suite of business packaging solutions goes beyond the mundane, offering a spectrum of customizable options, from sturdy yet visually appealing boxes to packaging that amplifies your brand story and blends creativity and functionality to leave a lasting impression on your customers.

“Packaging is an experience.”

When it comes to shipping products, ensuring proper protection during transit is paramount. This entails using appropriately sized boxes and adding packing materials to prevent movement within. If your items exceed the dimensions of a mailer, utilizing a shipping box becomes necessary. The utmost priority remains ensuring the safety of your products during transportation.

Furthermore, the selection of the right packaging communicates details about the product's quality, significance, and expected experience. This underscores the importance of packaging, which stands on par with the product itself.

Given the array of packaging and box choices available in the market, brands often face challenges in determining the optimal options for their products. This blog aims to provide insight into the diverse available options and assist in making informed choices.

Understanding Envelopes for Business Use

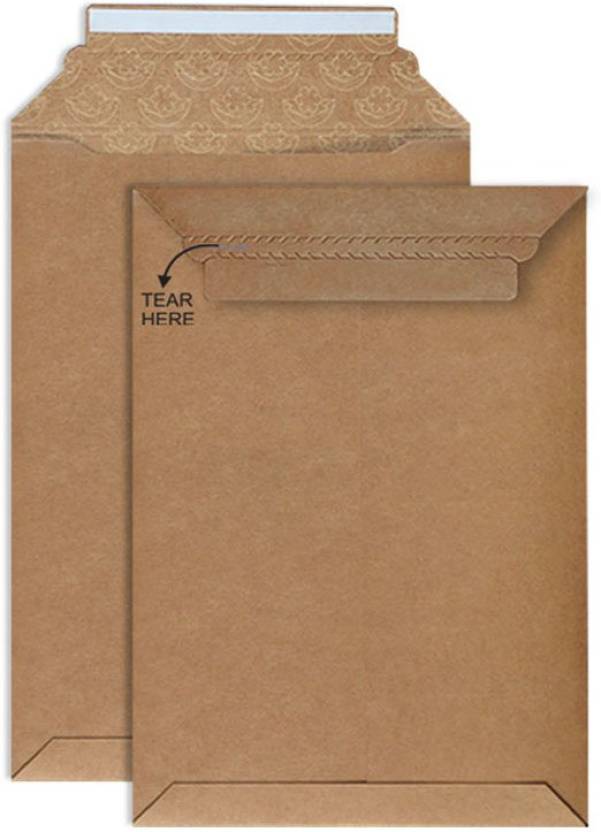

Envelopes also called flat mailers, serve as excellent packaging solutions for flat or thin, lightweight items such as apparel, books, picture frames, wallets, sunglasses, cosmetics, jewelry, and essential oils. Enhance the presentation of your business correspondence and products by using a premium selection of envelopes offered in the market. Whether you're sealing a vital document or delivering a personalized message, envelopes convey an aura of professionalism and sophistication. Available in various sizes, colors, and finishes, including Poly Mailers, Paper Bags, Standup Pouch, Bubble Mailers, Rigid Mailers, Padded Mailers, Tyvek Envelopes, Paper Envelopes, Ship-Lite Envelopes, Jiffy Rigi Bag Mailers, Glamour Mailers, Nylon Reinforced Mailers.

These can be made of paper, plastic bags/polyethylene, flat corrugated boxes, or cloth.

Common Types of Mailer Boxes

- Paperboard Box

Paperboard stands as a lightweight yet sturdy paper-based material renowned for its capacity to form custom shapes and structures swiftly. Its versatility makes it exceptionally well-suited for personalized packaging solutions. This material is derived by processing fibrous materials from wood or recycled waste paper, which are transformed into pulp through turning and bleaching processes. Available in various grades, each tailored to specific packaging requirements, paperboard offers flexibility in its applications.

Two primary options exist: Bleached and Kraft/CUK (unbleached "brown") paperboard. While both are commonly utilized, Kraft is favored for its eco-friendliness. However, it possesses lower moisture resistance, rendering it less suitable for wrapping food-related items or frozen goods compared to SBS.

- Corrugated Box

Corrugated material, often referred to as cardboard, is primarily recognized as the material used for large shipping, shoe, storage, and moving boxes. Comprising three layers of paper, an outer liner, an inner liner, and a corrugated medium known as fluting-this construction grants cardboard its durability and rigidity.

This packaging material is predominantly crafted from recycled raw materials, presenting an environmentally friendly aspect. A notable advantage is its recyclability, allowing it to be reused multiple times. Corrugated boards come in various types such as single-faced, double-faced, twin-wall, and triple-wall, each offering distinct features, performance, and strength. This versatility in construction materials enables the production of packaging tailored to specific needs. Increasingly, corrugated packaging has gained prevalence in e-commerce and product packaging. Its popularity stems from being a budget-friendly, lightweight, and cost-effective solution that provides effective protection for items during transit through the mail.

- Rigid Boxes

This type of packaging finds its typical usage in luxury items or high-end electronics. Resembling corrugated material, it distinguishes itself by being crafted from highly condensed paperboard, rendering it significantly stronger. Its thickness measures four times more than that of a standard folding carton.

While this packaging option stands as one of the more expensive choices within the realm of corrugated materials, its elevated cost is justified. It serves as a signal to customers that the product enclosed merits the premium packaging. However, a notable drawback lies in its inefficiency concerning space utilization. While companies like Apple have excelled in optimizing air-reduction inside the box, not all manufacturers can achieve this, leading to shipping inefficiencies due to oversized packaging.

- Chipboard Packaging

This particular packaging type finds widespread use across various industries, commonly observed in electronics, medicine, food, cosmetics, and even certain beverage sectors. Another variant of paperboard, sourced from reclaimed paper stock, it boasts the flexibility to be cut, folded, and shaped into nearly any desired form, making it an exceedingly cost-effective option.

Chipboard, available in diverse densities and strengths, does have limitations regarding its suitability for heavy items. Primarily designed for lightweight products such as cereal, tissue boxes, and various household items, it might not withstand substantial weight. Moreover, storage poses a challenge as chipboard structures can weaken and disintegrate swiftly in the presence of moisture. Hence, this packaging option is best suited for products that are already sensitive to such environmental factors.

Comparative Analysis: Durability and Protection

Cardboard stands out as an exceptionally durable packaging material, often considered the optimal choice for businesses. Its robustness plays a crucial role in safeguarding products by preventing moisture intrusion, a critical factor for items enduring lengthy transportation periods and for protecting food products.

In contrast, envelopes offer an aesthetic and minimalist packaging approach, ensuring durability through additional protection, utilizing high-quality PE foam and sturdy kraft paper. Padded envelopes, once utilized and separated into two parts, can be recycled, promoting their eco-friendly disposition.

Environmental Impact and Sustainability

The environmental footprint of envelopes depends on several factors. While paper envelopes originate from trees, a renewable resource, and are often recyclable or made from recycled paper, their overall eco-friendliness is influenced by various stages in their production, distribution, and delivery. In 2023, the sustainability of direct mail has emerged as a prominent topic. Both large corporations and individuals are displaying heightened interest in the sourcing and manufacturing processes of envelopes, emphasizing a growing awareness of environmental impact.

Cardboard is biodegradable and can be used as compost material. One ton of corrugated cardboard generates 538 kg of carbon equivalent emissions in its entire life cycle. Typically, cardboard boxes and shipping cartons undergo processing without bleach as they do not require a pristine white appearance. According to the New York Department of Environmental Conservation, over 97% of corrugated cardboard boxes have non-toxic water-based printing. The U.S. recovers about 70% of all corrugated cardboard boxes for recycling; it makes up the bulk of paper recycling.

Cost Considerations: Pricing and Budgeting

The cost of shipping, warehousing, and fulfillment is greatly influenced by the materials, dimensions, and weight of your packaging. Inefficiencies in packaging can lead to substantial financial losses, amounting to thousands or even millions of dollars annually. However, by revamping your packaging design, selecting appropriate materials, and reducing sizes, substantial cost savings can be achieved on a yearly basis.

Emphasizing compact packaging, minimizing inserts, and adopting standardized packaging practices prove to be highly cost-effective solutions. Keeping packages as small as possible not only helps in reducing shipping and logistics expenses but also contributes to environmentally friendly practices, promoting green packaging initiatives.

Customization and Branding Opportunities

A well crafted branded mailer box can significantly benefit your business. Beyond leaving a memorable impression on customers, it serves to distinguish your brand amidst competitors. Mailer boxes adorned with your company logo enhance brand visibility within the market, amplifying recognition among consumers.

Custom packaging holds substantial significance for every product-based business. It not only elevates brand recognition and awareness but also contributes to an enhanced customer experience. Moreover, it plays a pivotal role in safeguarding products from potential damage, ensuring their safe transit to customers.

Size and Weight Implications for Shipping

The dimensions provided on a shipping box typically refer to its interior measurements, encompassing the length, width, and height. These specifications assist in determining whether your item will properly fit within the box. However, when you pack your item inside the box and prepare it for shipping, you'll need to measure the outside dimensions of the shipping box. Carriers base their shipping fees on these external measurements.

Measuring the package dimensions involves gauging the length, width, and height of the box from the outside using measuring tools such as a ruler or tape measure. To record your box measurements accurately, it's advisable to have a pencil and a piece of paper handy to note down the external dimensions of the box.

Different shipping carriers have different criteria for limits to package dimensions and weight.

USPS size and weight limits are:

- 108 inches in length

- 130 inches in combined length and girth

- 70 lbs in weight

UPS size and weight limits are:

- 108 inches in length

- 165 inches in combined length and girth

- 150 lbs in weight

FedEx Ground size and weight limits are:

- 108 inches in length

- 165 inches in combined length and girth

- 150 lbs in weight

Customer Experience and Presentation

A customer's interaction with a brand spans various stages throughout their buying journey. Among these stages, one of the most pivotal moments is the unboxing experience. This moment occurs when a customer opens their package and encounters their purchase for the first time. The unboxing experience holds immense importance as it has the potential to significantly influence customer satisfaction and foster brand loyalty.

Brands have several key points to craft a positive unboxing experience for their customers. Here are a few tips:

- Use high-quality materials and construction.

- Design packaging that’s appealing to look at.

- Personalize the packaging.

- Make the product packaging easy to open.

- Include a clear call to action.

Unboxing marketing extends beyond merely displaying a product; it commemorates the arrival of that product into a customer's life. By transforming this moment into a noteworthy event worth sharing, brands not only cultivate a deeper connection with their audience but also generate captivating content that others find compelling and are eager to engage with and share.

Case Studies: Apple strategically leverages its product packaging to fulfill its brand promise and bolster its intelligent marketing approach.

Consistent with the brand's signature aesthetic of simplicity and cleanliness, the iPad's packaging stays true to Apple's identity. The cover art on the box features a life-size photo of the product without any textual marketing content. This choice serves as a compelling marketing message, creating anticipation and positioning the product as the focal point. The packaging predominantly showcases the Apple logo and the product name on the sides, while concealing product specifications and copyright details discreetly at the bottom backside. This design approach ensures that the brand remains the center of attention, aligning seamlessly with the overall brand image.

The packaging reflects the same level of elegance, cleanliness, and user-friendliness characteristic of other Apple products. Opening the box echoes the familiar experience of unpackaging an iPhone or iPod, delivering the simplicity and consistency that Apple customers anticipate and appreciate. Even the packaging materials, such as the silk paper stock and the "how to use" card, exude premium quality, featuring a soft, rich finish, a subdued varnish, a slightly creamy hue, and a silver metallic foil stamp on the Apple logo. This attention to detail extends the tactile satisfaction to the packaging itself, aligning it as an extension of the product. Instead of opting for cost-saving measures with subpar packaging and materials, Apple integrates the packaging seamlessly with the product, embodying an extension of its quality.

Apple's marketing strategy highlights the product's intuitive nature, emphasizing the ease of use. The minimalistic approach extends to the user instructions, which are streamlined and concise, guiding users to find detailed instructions online or within the product itself. This strategy caters to the familiarity of existing Apple users while ensuring a user-friendly experience even for first-time Apple users.

The iconic red and yellow box of the McDonald’s Happy Meal has a special ability to bring smiles to children's faces. This packaging evokes joy and excitement as kids eagerly anticipate the toy enclosed within. Additionally, for adults, the box often sparks nostalgic memories.

Having existed for over 40 years, the Happy Meal has played a pivotal role in establishing McDonald’s as a family-friendly brand. While the packaging design has undergone evolution, its fundamental structure has remained consistent. In the past, the box featured puzzles and mazes, whereas the current version showcases a minimalist design with vibrant red and yellow colors. This modern approach aims to evoke happiness in recipients, complementing the toys provided with each meal.

Here are the key lessons for your dream branded packaging:

- Know what your customers expect from your brand and deliver it in all aspects of your product, ranging from its design to the packaging used for shipping.

- Your brand is much more than your logo: it encompasses every interaction a customer has with your business. Assess all touchpoints with your customers to ensure they authentically reflect your brand.

- Simplify your message and communicate it as directly as possible. Condense your copy to its essence, and whenever feasible, utilize visuals to convey your message effectively.

- Be you, all the time. Successful brands convey a company's persona in a manner that transcends a mere commercial entity. Your brand persona should mirror who you are and what sets you apart from other companies in your industry. Ensure consistency in portraying this identity, and always remain true to your brand values.

Future Trends in Packaging for Businesses

There's a growing emphasis on using packaging materials that are sustainable, biodegradable, and easily recyclable, aligning with eco-friendly practices to reduce environmental impact. With the rise of e-commerce and direct-to-consumer models, there's an increasing demand for personalized and custom packaging solutions that enhance brand identity and customer experience.

Integration of digital technologies, automation, and the Internet of Things (IoT) in packaging processes to improve efficiency, traceability, and interactive consumer engagement. Packaging designs incorporating creativity, simplicity, humor, and distinctive fonts to capture consumer attention. Interactive and active packaging that shares stories or establishes connections with consumers to stand out in the competitive market.

These trends collectively reflect the evolving landscape of the packaging industry, driven by the need for sustainability, technological advancements, personalized experiences, and engaging storytelling approaches to appeal to modern consumers.

Choosing Between Mailers And Shipping Boxes

Determining whether to use mailers or shipping boxes depends on various factors such as business size, budget, and shipping frequency. Consider the following points to make an informed decision:

Protection Needs: Mailers typically use fewer materials than shipping boxes, potentially offering less protection. For fragile items, especially larger ones, consider using shipping boxes unless they're small enough to be adequately protected by bubble wrap.

Size and Weight of the Product: Shipping boxes generally cost more to ship but accommodate larger sizes and heavier weights. However, shipping heavy items in mailers might pose challenges.

Budget Consideration: Shipping boxes may incur higher costs per box and per shipment. If these costs can be factored into the item's overall price, it might not pose an issue.

Reusability: Shipping boxes are often reusable, while mailers are typically best suited for one-time shipments. Consider the lifecycle of your packaging and how it aligns with your shipping needs.

Efficiency in Packing: Assess the efficiency and ease of packing using both mailers and shipping boxes. Consider time taken, ease of use, and practicality in your decision-making process.

Evaluating these elements will guide you toward choosing the most suitable packaging solution for your business. If you're seeking dynamic packaging solutions, reach out to us today to explore how our offerings can elevate your business beyond mere packaging, enhancing your overall brand experience.